Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10 results about "Water cooled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water cooling is sometimes referred to as liquid cooling, because various other substances are sometimes used instead of, or in addition to, water.

Method and device for preparing iron nitride material by double promotion of nanocrystallization and strong magnetic field

InactiveCN101607701APromote formationSuppress generationNitrogen-metal/silicon/boron binary compoundsIron powderIron nitride

The invention relates to a method and a device for preparing iron nitride material by double promotion of nanocrystallization and a strong magnetic field. An electrical heating body and a water cooling sleeve are sequentially arranged outside the inner stainless steel wall of the device, and a magnetic field generating device is arranged outside the water cooling sleeve. The method for preparing iron nitride comprises the following steps: firstly, preparing pure nanometer iron powder or pure nanometer iron films; putting the iron powder or the iron films into the device; leading in hydrogen gas; preserving heat for 10-90 minutes at 300-450 DEG C; naturally cooling to 60-100 DEG C, applying a magnetic filed of 6-20 T by the magnetic field generating device at the temperature, and leading in ammonia gas at the same time; raising the temperature in a reactor to 120-250 DEG C and preserving for 8-30 hours; and naturally cooling to room temperature. In the invention, nitridation reaction can be carried out in the condition of low temperature, which is beneficial to the formation of alfa''-Fe16N2 and the inhibition of the generation of other iron nitride substances. The content of the prepared iron nitride material alfa''-Fe16N2 reaches 65-99 percent.

Owner:NORTHEASTERN UNIV LIAONING

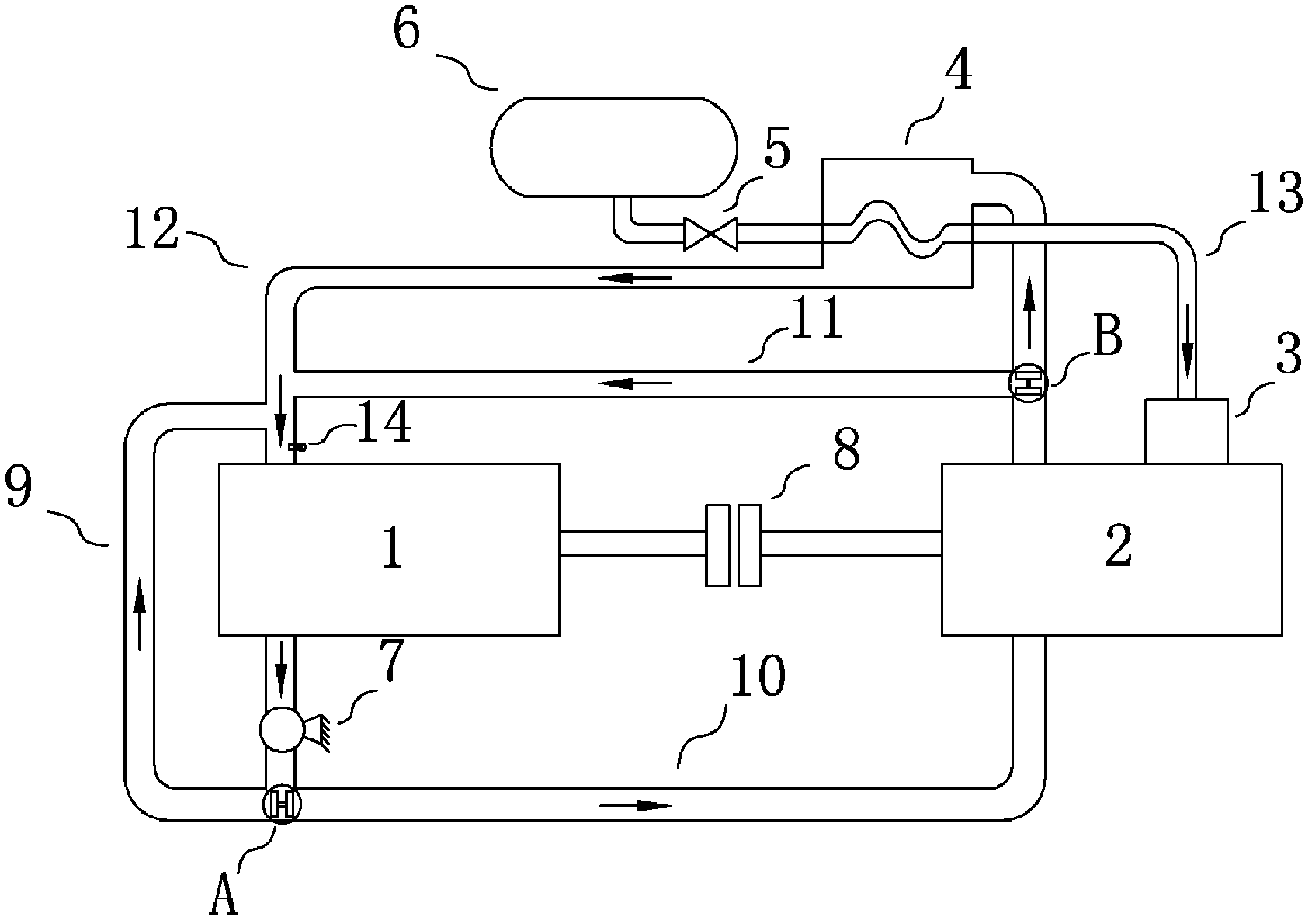

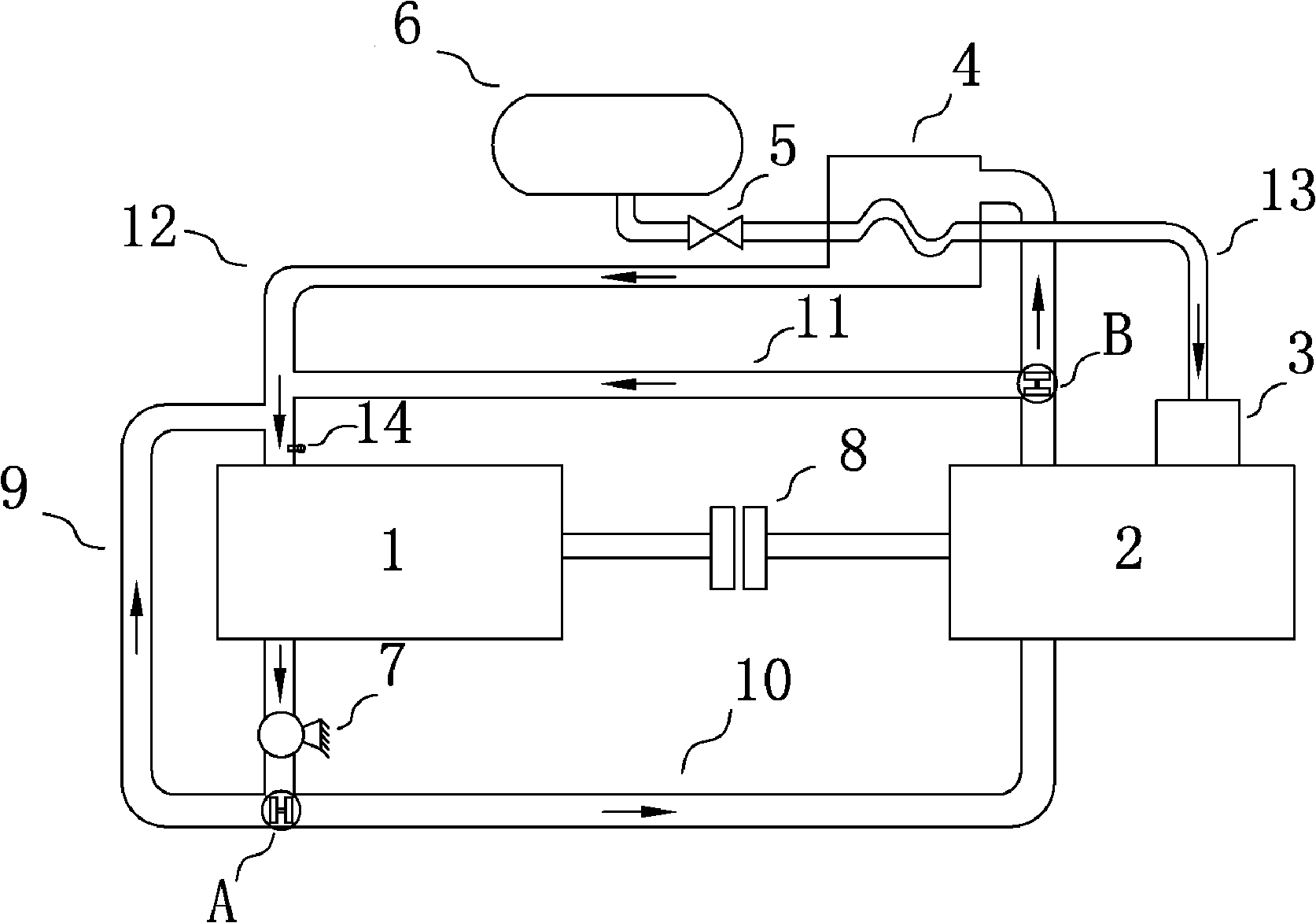

Pneumatic and internal combustion hybrid system based on multi-stage utilization of afterheat of cooled water

InactiveCN102505998AImprove working environmentIncrease cycle power outputCoolant flow controlInternal combustion piston enginesThermostatInlet pressure

Owner:ZHEJIANG UNIV

Sterilizing and softening method and sterilizing and softening device for exchanging heat of water into and out of water heater

InactiveCN101769592AReduced risk of burnsEfficient productionSolar heating energySolar heat devicesTemperature controlPotable water

The invention discloses a sterilizing and softening method for exchanging heat of water into and out of a water heater. A heat exchange interface of delivered hot water / boiling water and inlet water is adopted based on a water heater / water boiler with a temperature control device and the heat exchanged hot water is continuously heated, wherein the hot water / boiling water continuously exchanges heat with the inlet water when delivered. A sterilizing and softening device manufactured according to the method for exchanging the heat of the water into and out of the water heater consists of the water heater / water boiler with the temperature control device and a water inlet / outlet connection pipe. The device is characterized by comprising the heat exchange interface of the hot water / boiling water and the inlet water to be sterilized and softened. The method and the device has the advantages that the heat exchange of the hot water / boiling water and the inlet water can reduce the heating time, enables the production of purified water to be more effective and is favorable for saving energy; and the water boiler for providing drinking water can deliver the boiled water cooled to between 30 and 50 DEG C so as to shorten the time of waiting for the cooling of the drinking water, and reduce the danger of scald when the school students drink the boiled water. Two embodiments are provided with attached figures.

Owner:施中天

Multifunctional electron beam zone melting furnace

PendingCN111118596AMeet the smelting methodSynchronized Coordinated MovementsPolycrystalline material growthBy zone-melting liquidsAutomatic controlZone melting

Owner:GRIMAT ENG INST CO LTD

Combined type air conditioning unit with double cooling systems

PendingCN113757854ADistribute quicklyIncrease temperatureLighting and heating apparatusAir conditioning systemsElectric machineryEngineering

Owner:盐城市力马空调工程有限公司

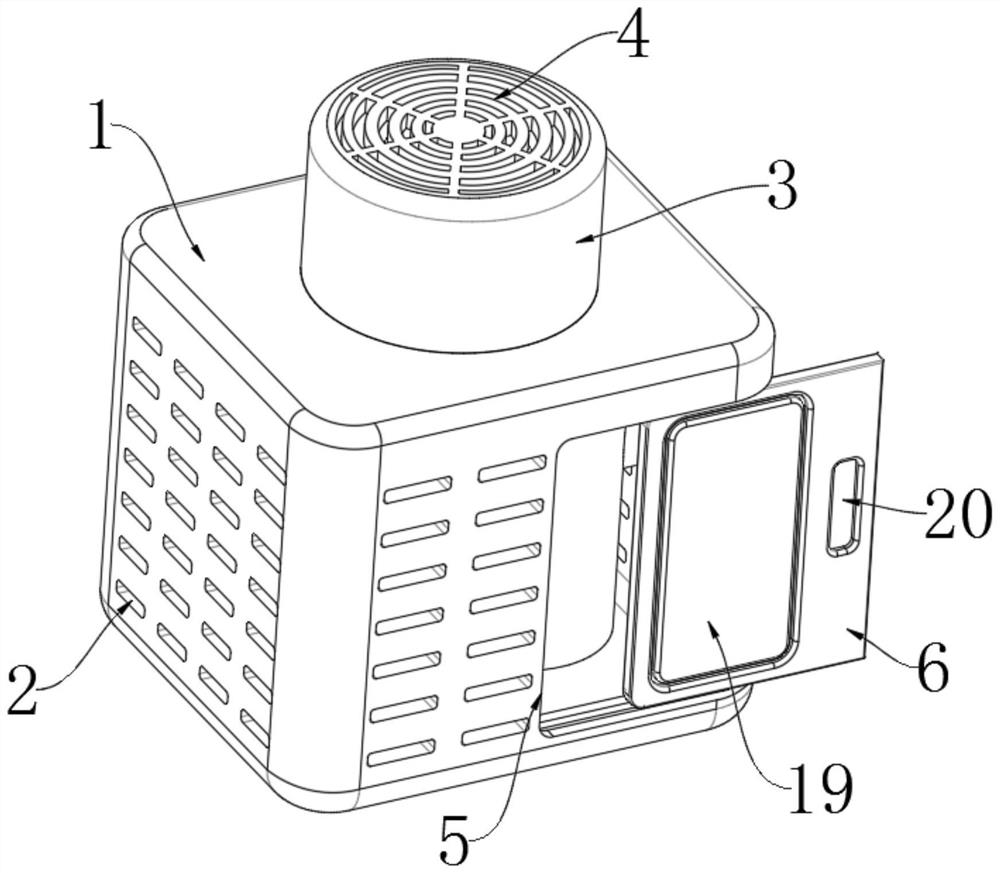

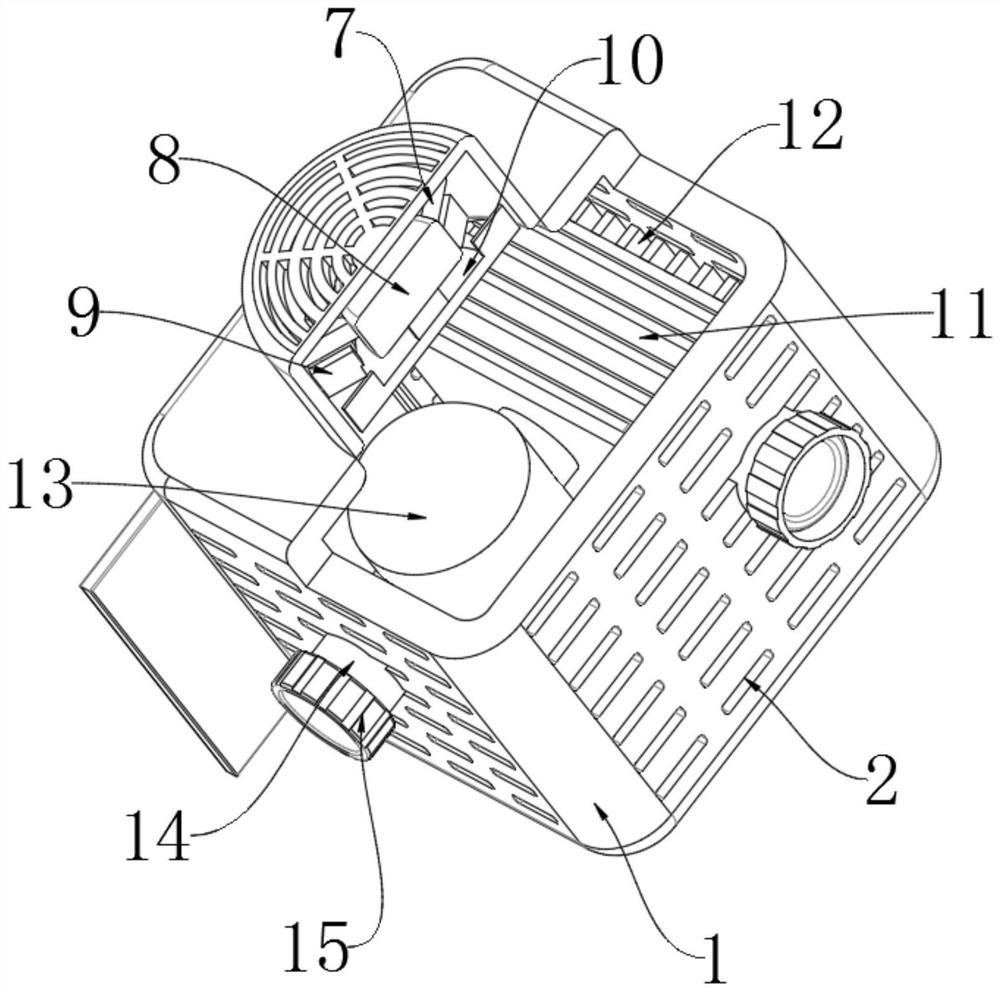

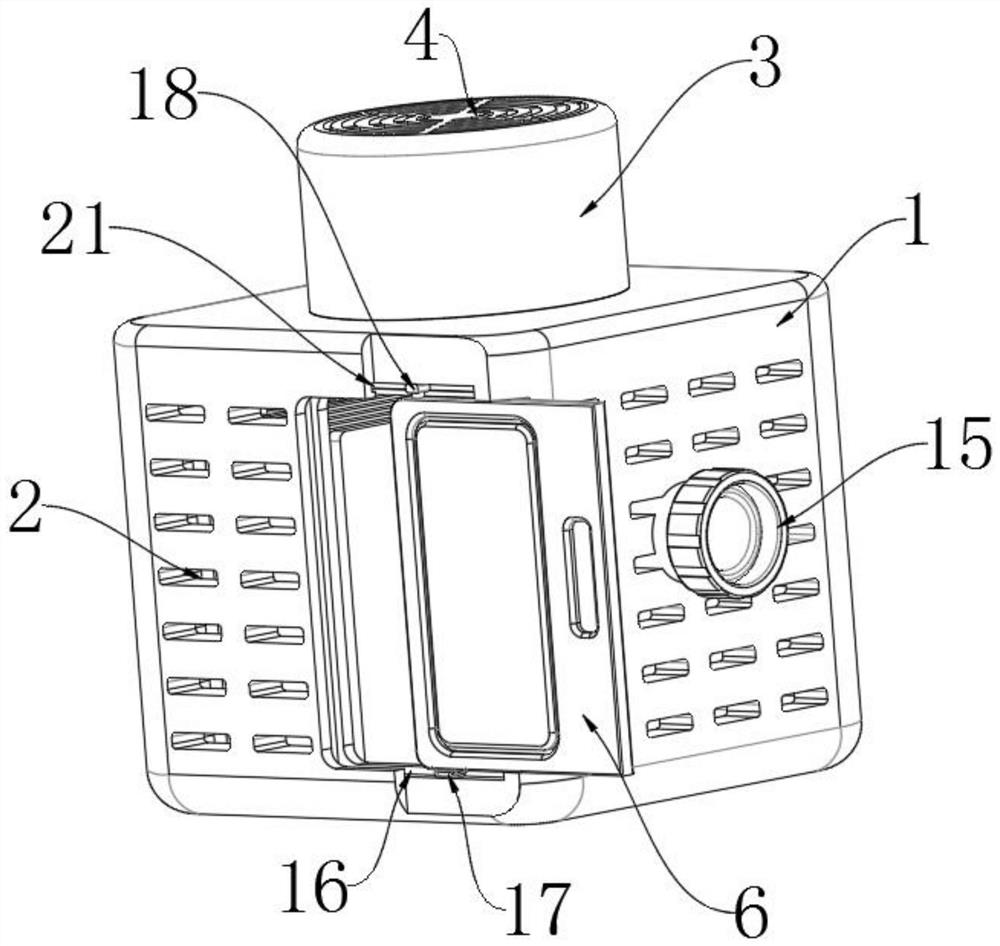

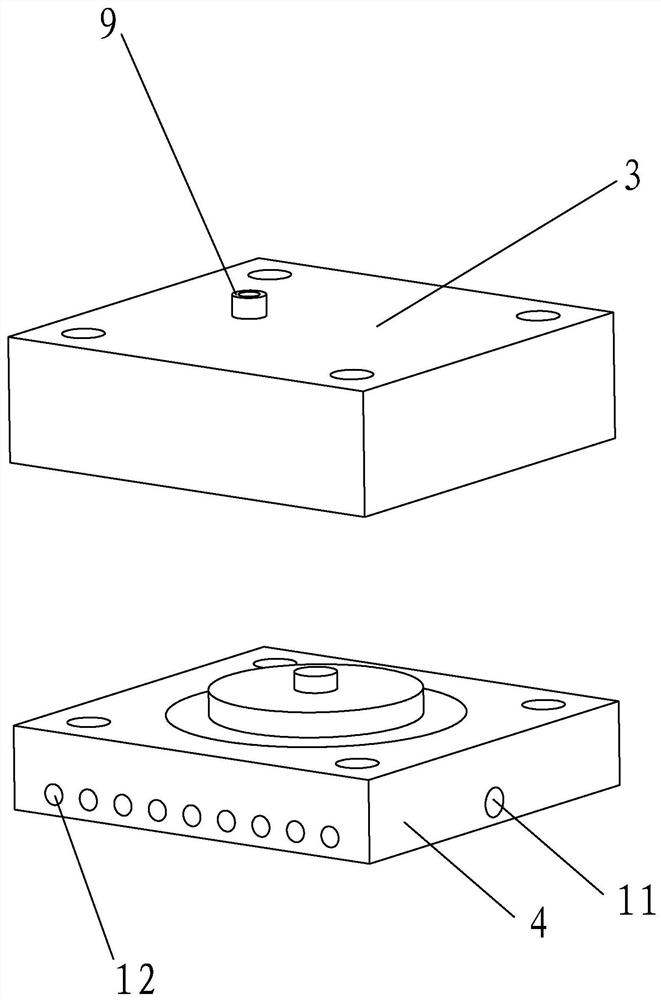

High-efficiency water-cooling computer radiator

InactiveCN112947716AEfficient heat dissipationImprove cooling effectDigital data processing detailsEngineeringMechanics

The invention provides a high-efficiency water-cooling computer radiator which comprises a shell, cooling fins, a water-cooling device, a mute fan and an exhaust fan, wherein the interior of the shell is divided into three parts, the exhaust fan is arranged on the leftmost side, the water-cooling device is arranged in the middle, the mute fan is arranged on the rightmost side, a ventilation pipeline is installed in the water-cooling device, an air inlet is formed in the left end of the ventilation pipeline, an air outlet is formed in the right end of the ventilation pipeline, cooling fins are installed on the surface of a shell of the radiator, a water inlet and a water outlet are formed in the bottom of the shell, and water cooling liquid in the water cooling device can be replaced conveniently. The water cooling device and the mute fan are combined together, heat dissipation can be conducted on a computer more efficiently, the heat dissipation effect is better, water cooling liquid in the water cooling device can be replaced at any time through the water inlet and the water outlet in the lower portion of the shell, and use is convenient.

Owner:TIANJIN YUDONG AUTO PARTS CO LTD

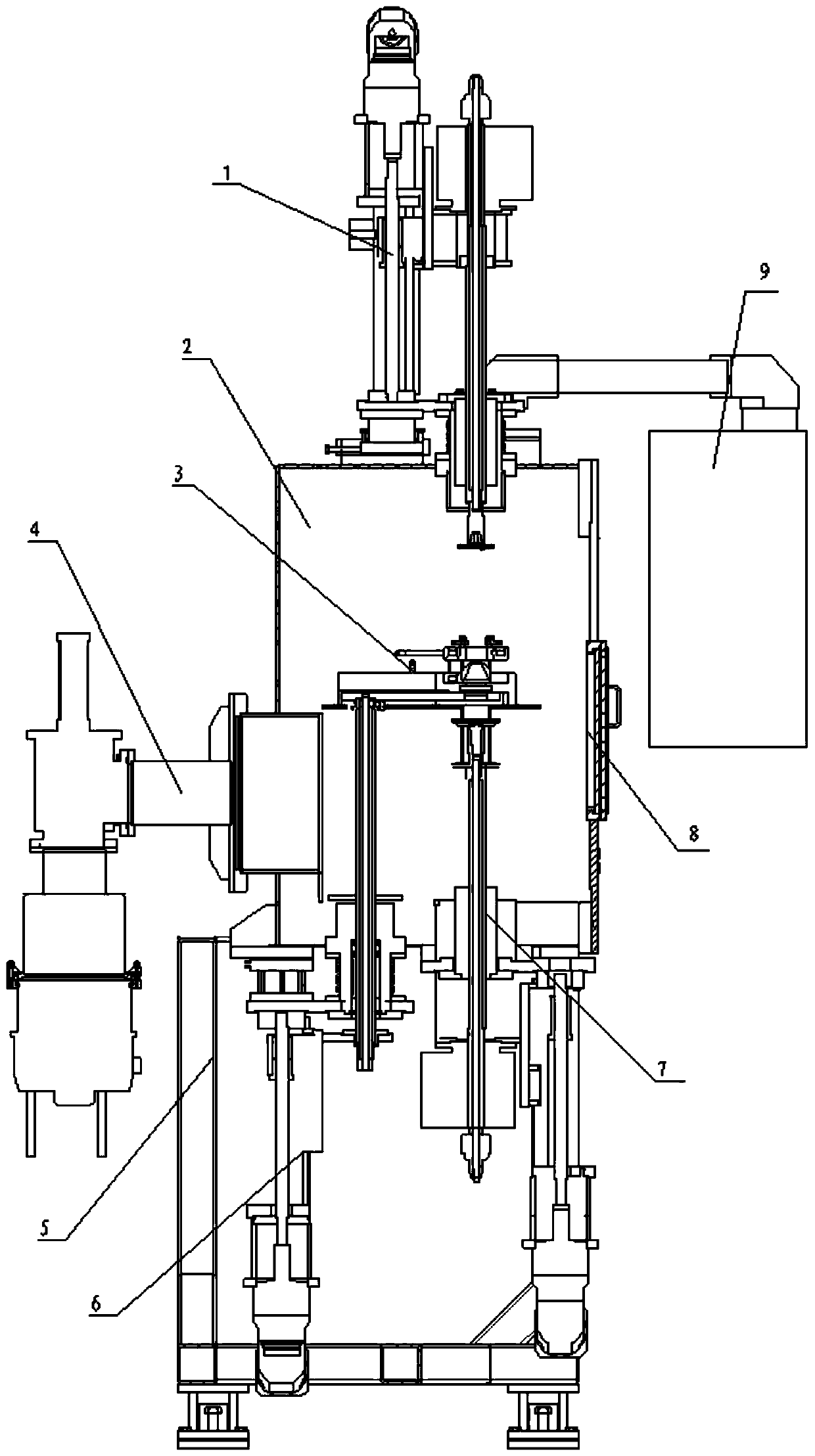

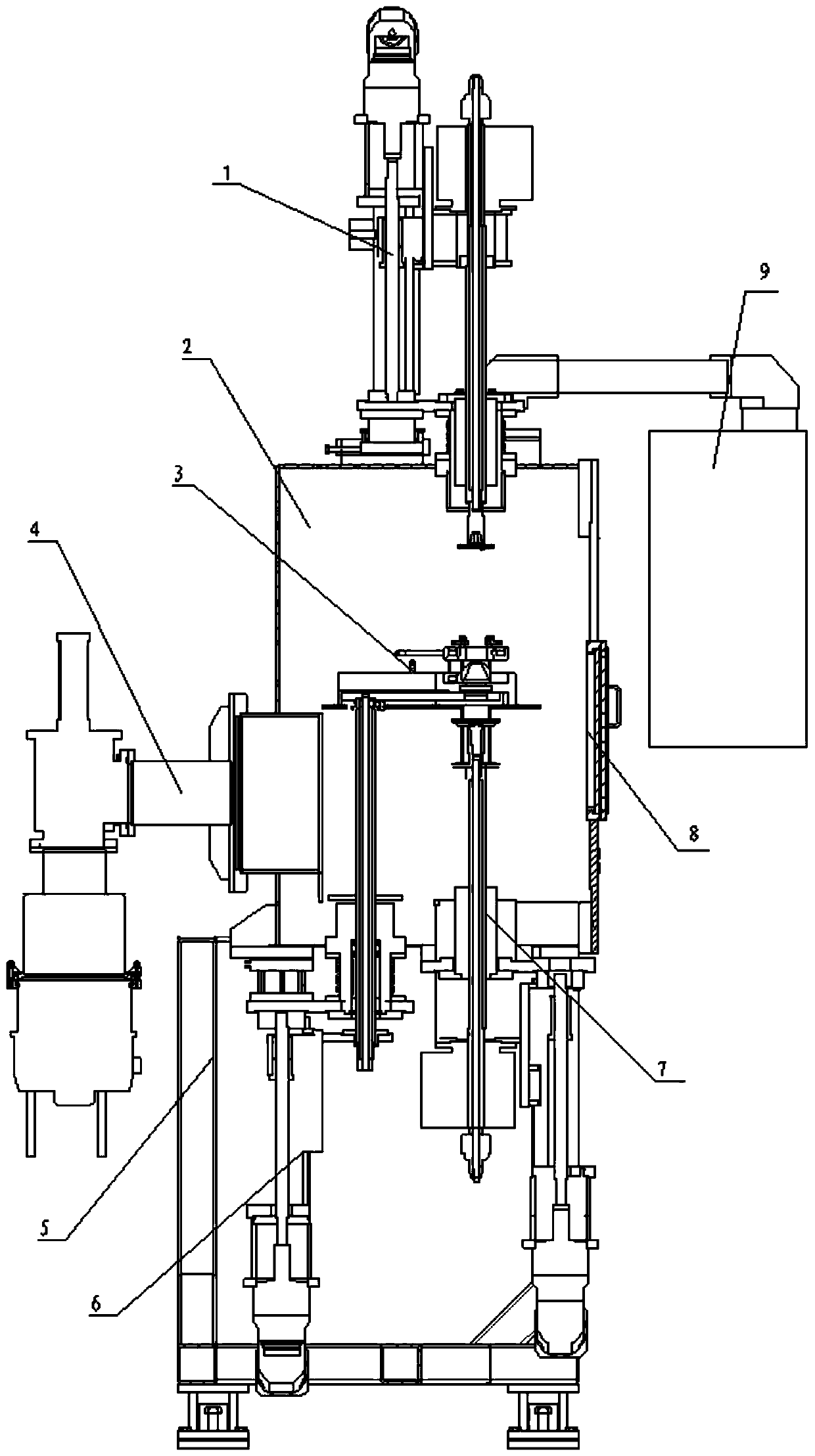

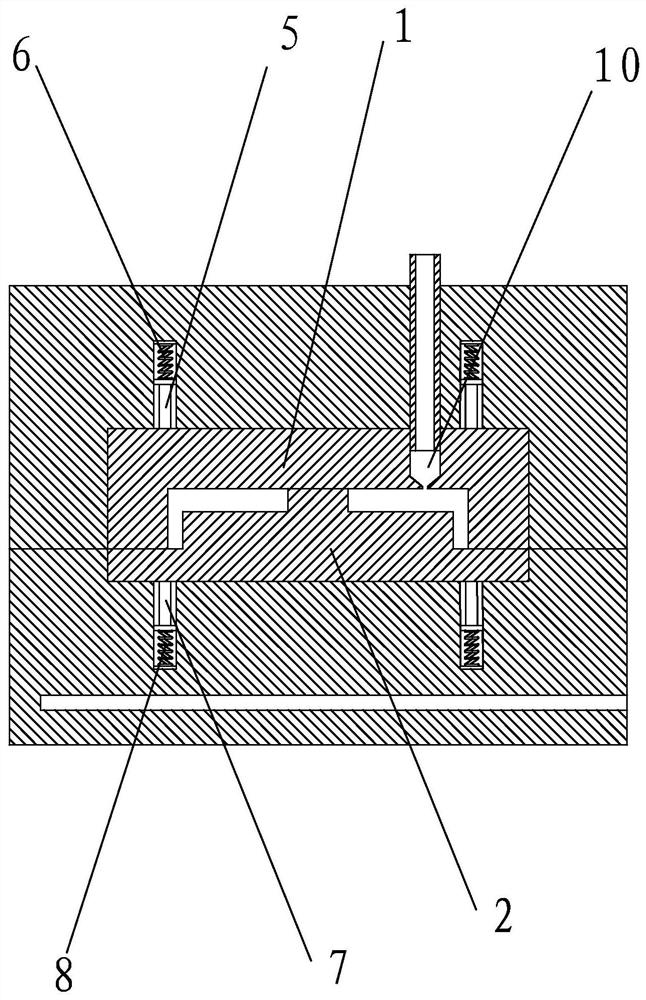

A kind of supporting wheel manufacturing equipment and supporting wheel manufacturing process

ActiveCN111687382BClosed tightlyGuaranteed accuracyFoundry mouldsFurnace typesManufacturing technologyMachined surface

Owner:泉州市宏山工程机械有限公司

Vertical pump structure

ActiveUS20200325907A1Avoid accumulationPrevent leakageEngine sealsPump componentsEngineeringStructural engineering

A vertical pump structure is adapted to be mounted on a water cooling tank. The vertical pump structure comprises a pump casing, an upper shaft seal, a shaft and a lower shaft seal assembly. An upper annular flange and a lower annular flange are formed on an inner surface of the pump casing. A drain space is formed between the two annular flanges. A drain hole communicates with the draining space and an internal space of the water cooling tank. The shaft is inserted through the two annular flanges. Two gaps, which are formed between the shaft and the two annular flanges, are respectively sealed by the upper shaft seal and the lower shaft seal assembly. Therefore, even if the lower shaft seal assembly fails, the upper shaft seal can still prevent leaking fluid from polluting the work place.

Owner:WALRUS PUMP CO LTD

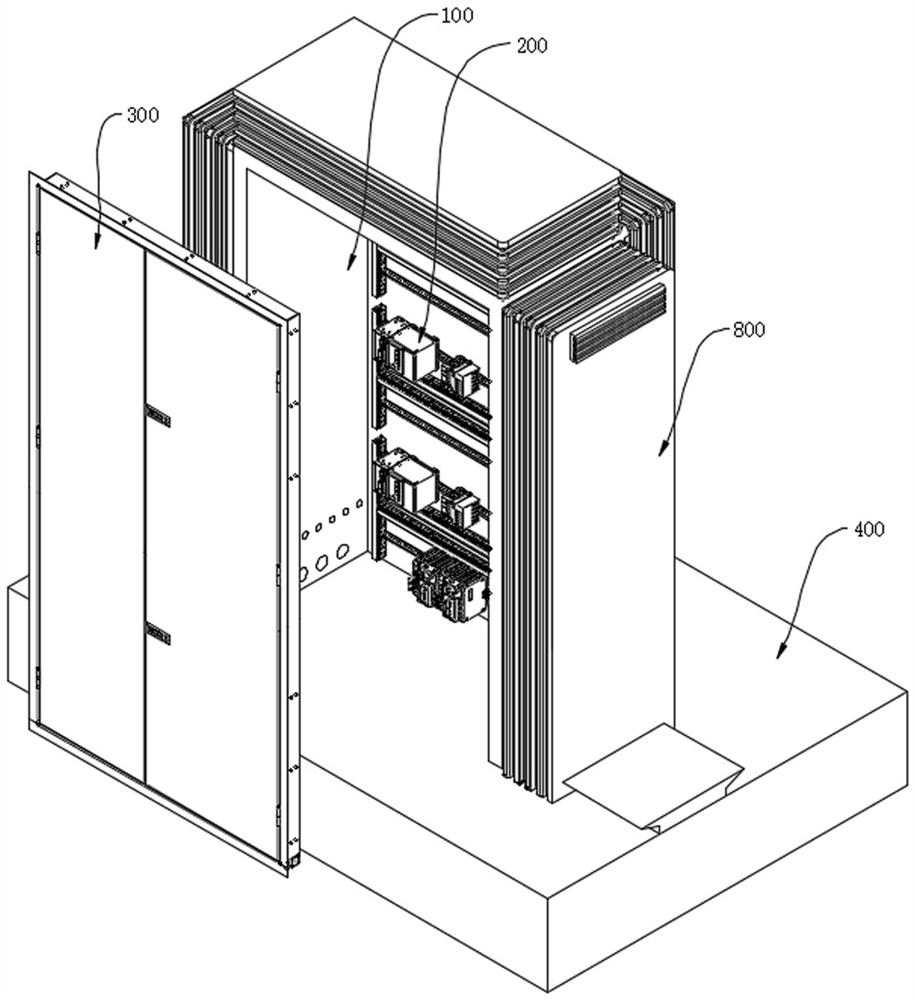

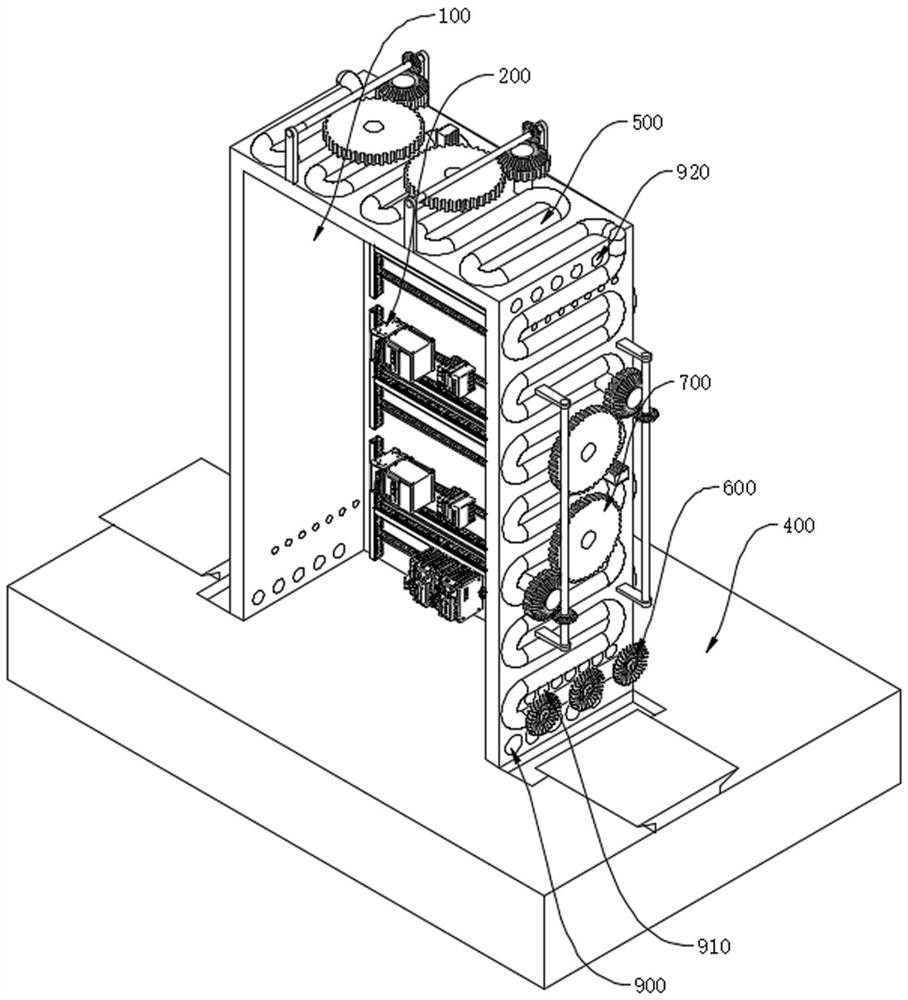

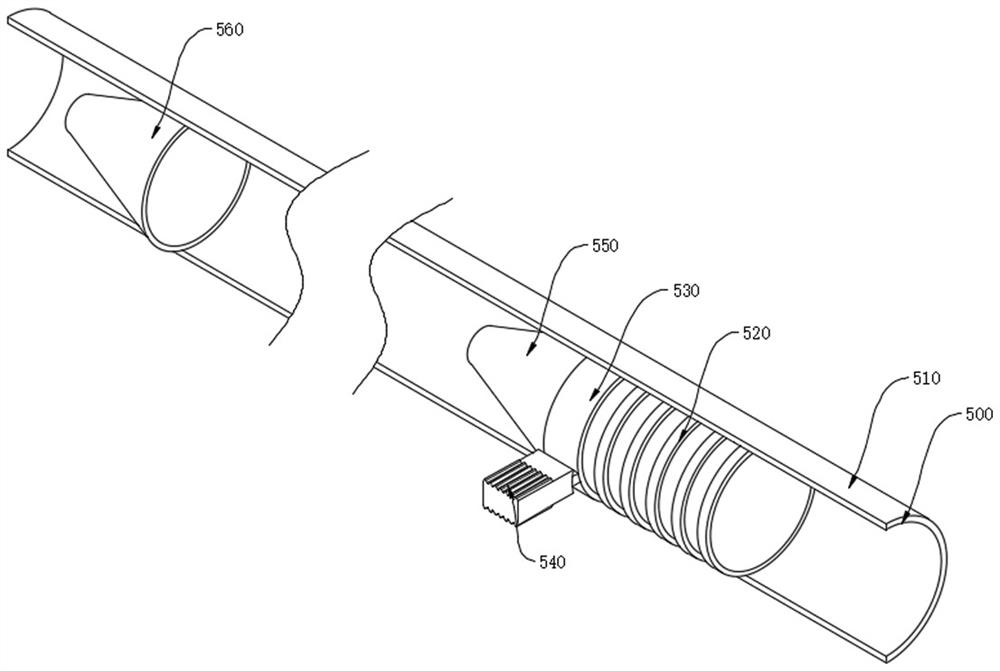

Self-adaptive temperature control type high-voltage switch cabinet for large-temperature-difference region

PendingCN114678796ATemperature recoveryRapid cooling treatmentSwitchgear detailsSubstation/switching arrangement cooling/ventilationTemperature controlEngineering

Owner:山东鼎盛电气设备有限公司

Deslagging system of hazardous waste melting furnace

The invention provides a hazardous waste melting furnace deslagging system which is arranged at a deslagging outlet in the bottom of a hazardous waste melting furnace and comprises a slag cooler body, a heating element, a rotary gear granulator, a cooling fan, a water cooling coil and a cooling nozzle, and the top of the slag cooler body is fixedly communicated with the bottom of the hazardous waste melting furnace; the heating element is arranged in a connector of the hazardous waste melting furnace and the slag cooler body; the rotary gear granulator is arranged on the slag cooler body; the cooling fan is connected with the ventilation pipeline and is communicated with the first ventilation opening of the slag cooler body; the first ventilation opening of the slag cooler body is connected with the slag cooler lower cone in the target tangential direction; the water cooling coil pipe is arranged between the outer surface and the inner surface of the slag cooler body; a first ventilation opening of the slag cooler body faces the cooling fan; and the cooling nozzle is arranged at the second position of the slag cooler body. Discharged molten glass bodies are granulated and cooled, and the slag discharging efficiency of the hazardous waste melting furnace can be improved.

Owner:CHONGQING UNIV +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap