A kind of supporting wheel manufacturing equipment and supporting wheel manufacturing process

A technology for manufacturing equipment and rollers, applied in the field of machinery, can solve problems such as mold precision drop, wear, and unfavorable product quality, and achieve the effects of speeding up the manufacturing process, improving molding accuracy, and improving manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

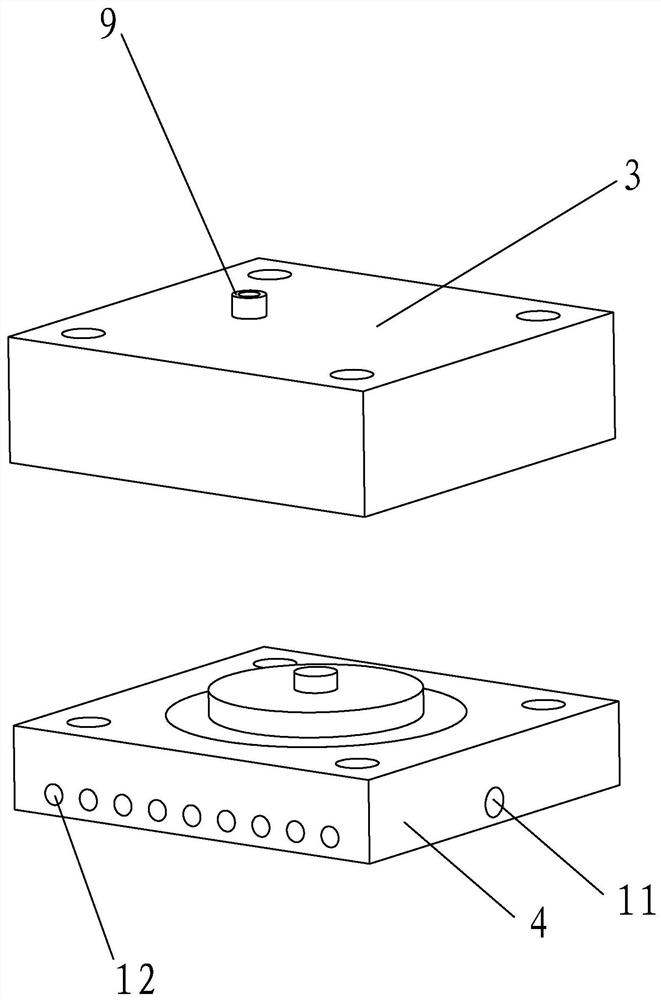

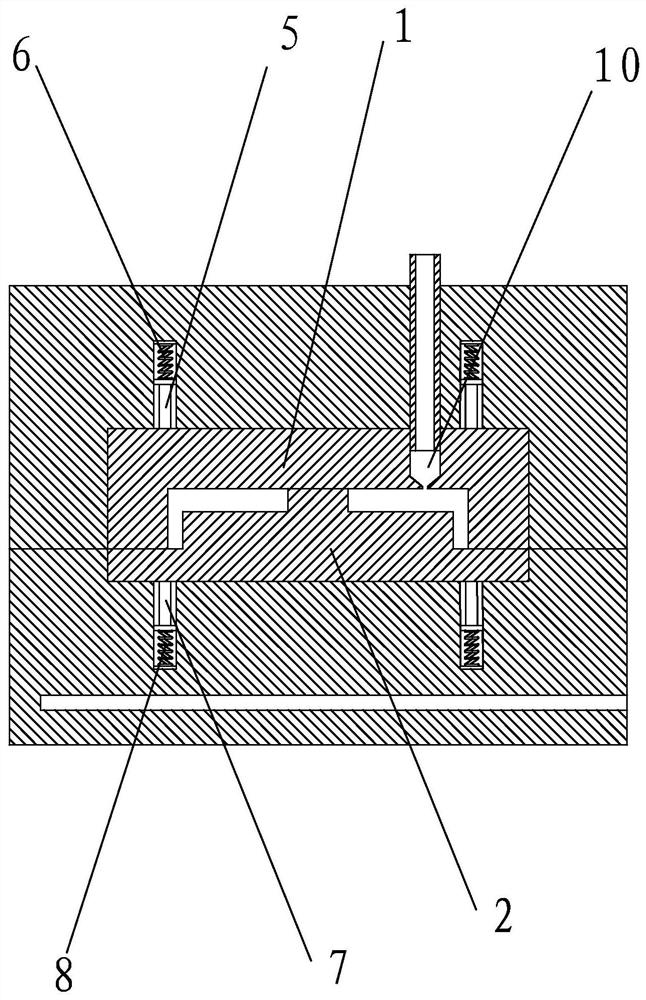

[0034] A kind of supporting wheel manufacturing equipment of the present invention, such as figure 1 with figure 2 As shown, it includes a first mold 1 and a second mold 2, and also includes a first supporting seat 3 for carrying and installing the first mold 1, and a second supporting seat 4 for carrying and installing the second mold 2; the first supporting seat 3 has pre-installed The first pretensioning device that tightens the first mold 1 and the second mold 2; in the actual use process, when the accuracy is reduced, the first mold and the first mold in the first support seat and the second support seat can be replaced by installation and disassembly. The second mould, thereby achieving the accuracy of the pouring mould; when the first support seat and the second support seat are closed, the first pre-tightening device can provi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap