Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5 results about "Hazardous waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hazardous waste is waste that has substantial or potential threats to public health or the environment. Hazardous wastes may be found in different physical states such as gaseous, liquids, or solids. A hazardous waste is a special type of waste because it cannot be disposed of by common means like other by-products of our everyday lives. Depending on the physical state of the waste, treatment and solidification processes might be required.

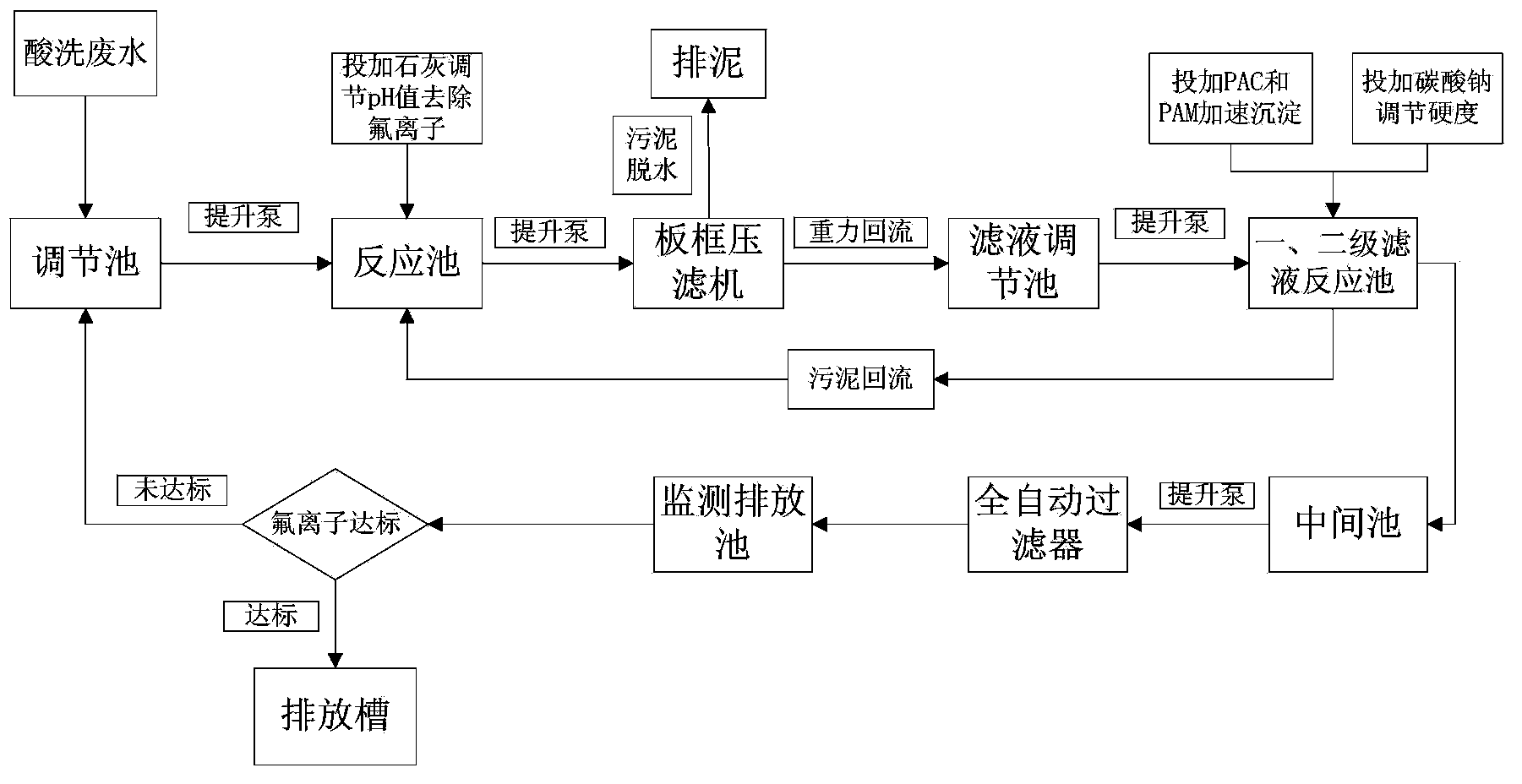

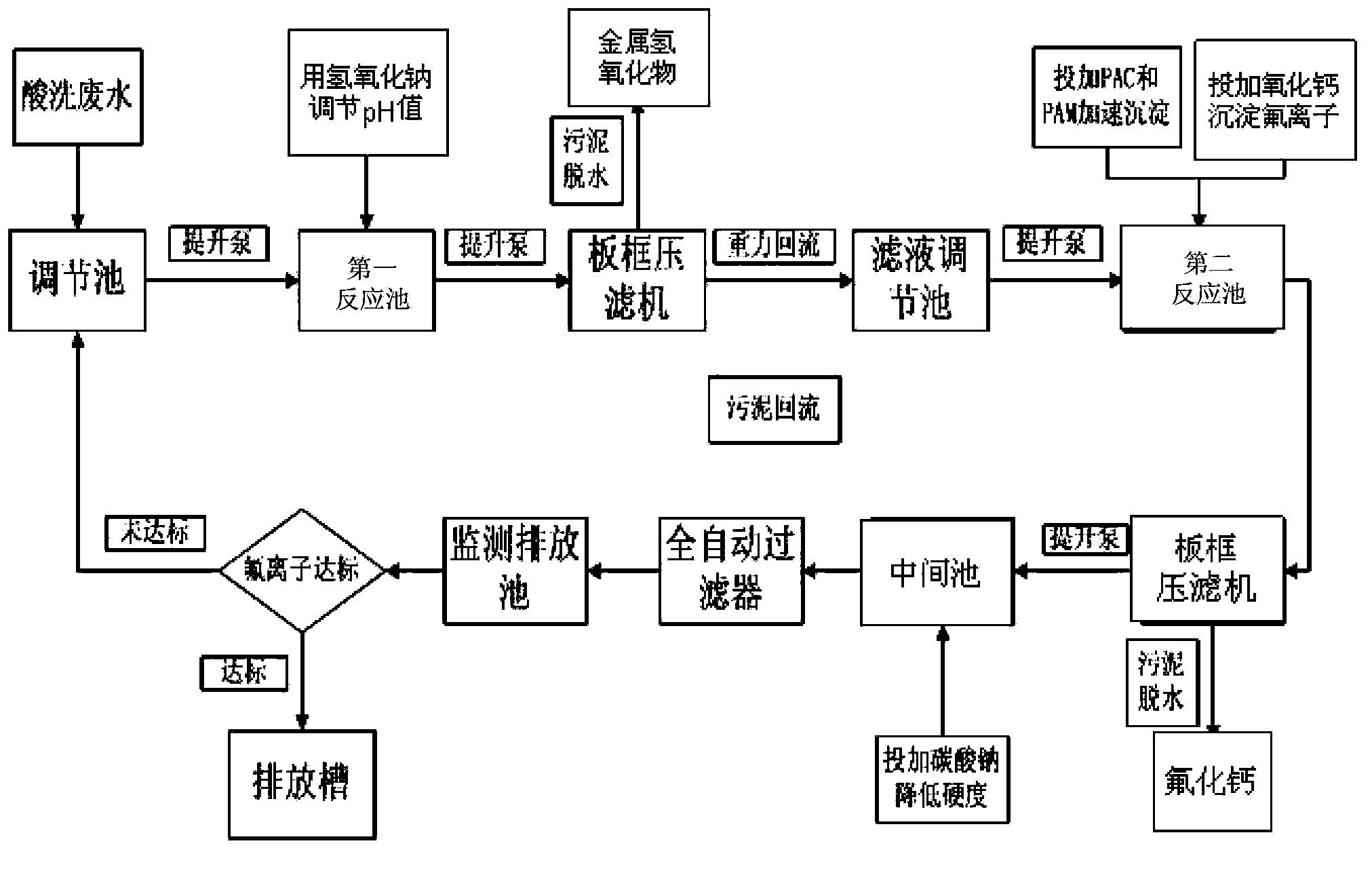

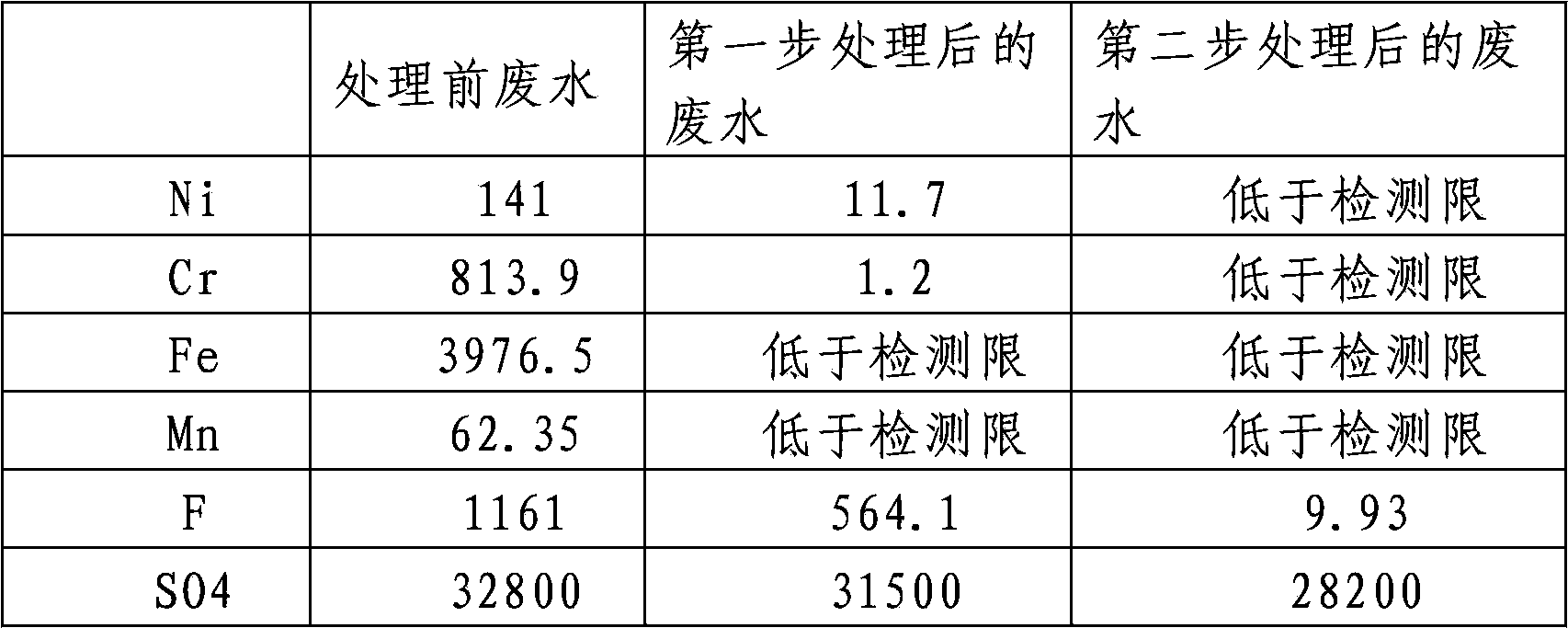

Double-alkali neutralization treatment method of heavy metal-containing acidic wastewater

Owner:宝钢特钢长材有限公司

Method for analyzing contents of fluorides in hazardous wastes

InactiveCN110057896AEasy to handleAvoid lostPreparing sample for investigationMaterial electrochemical variablesCombustionTest sample

The invention provides a method for analyzing the contents of fluorides in hazardous wastes. According to the method, a pretreated sample is completely combusted in an enclosed space by adoption of anoxygen bomb combustion technology; one part of the fluorine element in the oxygen bomb is absorbed by absorption liquid in the oxygen bomb and the other part is absorbed by absorption liquid in a gasabsorption station through a gas form; the absorption liquid is combined to obtain fluoride extracting solution; and the extracting solution is treated to obtain to-be-tested sample solution. Fluorine ion series standard solution is prepared; and a standard curve is drawn for a negative logarithm (E(Mv)-log cF-(mg / L))of the concentration of fluorine ions via a potential value E. An ion chromatograph-fluoride ion selective electrode is utilized to measure the potential value of the to-be-tested sample solution; and the content of the fluorides is calculated via the standard curve according tothe measured potential value. The method is relatively high in test result correctness and is capable of greatly shortening the test time at the same time.

Owner:JIANGMEN YAMEN NEW FORTUNE ENVIRONMENTAL PROTECTION IND CO LTD

Oxidative degradation method for cyanide in cyaniding tailings

InactiveCN107890622AReduce consumptionPromote decomposition and releaseChemical protectionVacuum extractionHigh pressure

Owner:FUJIAN SHUANGQISHAN MINING +1

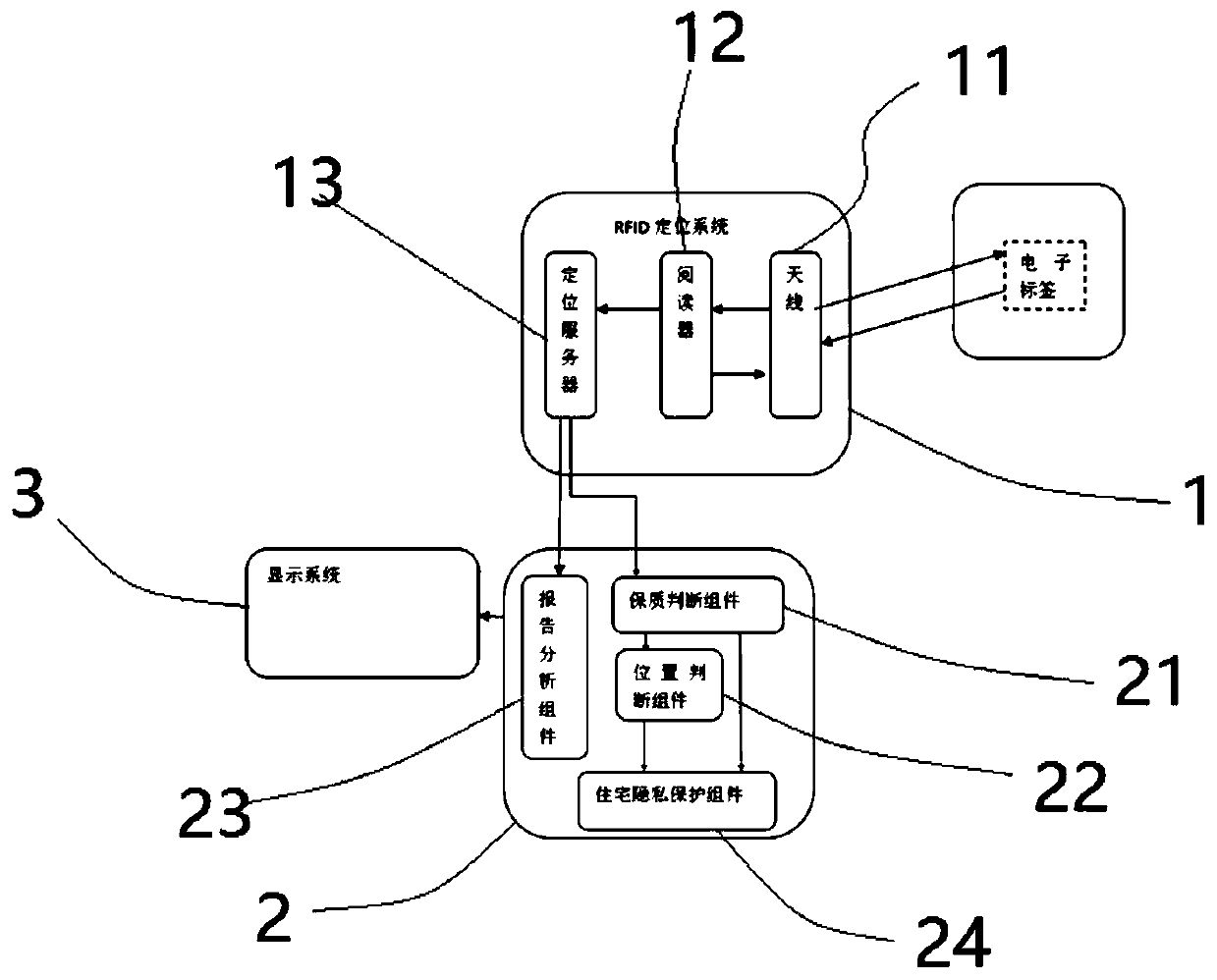

Dangerous waste positioning and recycling system based on RFID technology and dangerous waste judgment method

PendingCN110084386AAvoid pollutionMaster distribution in real timeSustainable waste treatmentData processing applicationsInformation processingEcological environment

Owner:CENT SOUTH UNIV

Deslagging system of hazardous waste melting furnace

The invention provides a hazardous waste melting furnace deslagging system which is arranged at a deslagging outlet in the bottom of a hazardous waste melting furnace and comprises a slag cooler body, a heating element, a rotary gear granulator, a cooling fan, a water cooling coil and a cooling nozzle, and the top of the slag cooler body is fixedly communicated with the bottom of the hazardous waste melting furnace; the heating element is arranged in a connector of the hazardous waste melting furnace and the slag cooler body; the rotary gear granulator is arranged on the slag cooler body; the cooling fan is connected with the ventilation pipeline and is communicated with the first ventilation opening of the slag cooler body; the first ventilation opening of the slag cooler body is connected with the slag cooler lower cone in the target tangential direction; the water cooling coil pipe is arranged between the outer surface and the inner surface of the slag cooler body; a first ventilation opening of the slag cooler body faces the cooling fan; and the cooling nozzle is arranged at the second position of the slag cooler body. Discharged molten glass bodies are granulated and cooled, and the slag discharging efficiency of the hazardous waste melting furnace can be improved.

Owner:CHONGQING UNIV +1

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap