High-efficiency spring production shaping device

A sizing device and high-efficiency technology, applied in the direction of manufacturing tools, manufacturing springs from wires, furnace types, etc., can solve problems such as quality impact, quality impact, and inability to cool springs, so as to achieve quality assurance and avoid softening and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

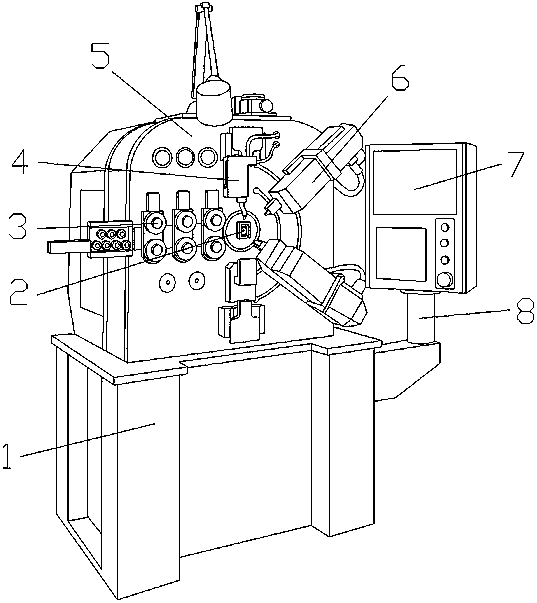

[0022] see Figure 1-Figure 4, the present invention provides a high-efficiency spring manufacturing sizing device, its structure includes a main base 1, a spring heating port 2, a conveying mechanism 3, a cooling device 4, a processing panel 5, a sizing spindle 6, a control panel 7, and a panel support 8, The panel support 8 has an L-shaped structure, and the slot at the lower left end is installed on the upper right side of the main base 1 by embedding, and the bottom of the control panel 7 is installed at the upper end of the slot at the panel support 8 by buckling. The bottom of the processing panel 5 is fastened with the upper end of the main base 1 and the right end of the surface is provided with two shaping spindles 6, and the middle position of the front surface of the processing panel 5 is provided with a groove for movable installation of the spring heating port 2, so The conveying mechanism 3 described above is mounted on the middle part of the left end of the front s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap