Ultrathin loudspeaker-type radiator and damping ultrathin radiator

A radiator and speaker technology, applied in sensors, electrical components, etc., can solve the problems of radiator vibration, equipment instability, ultra-thin radiator, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

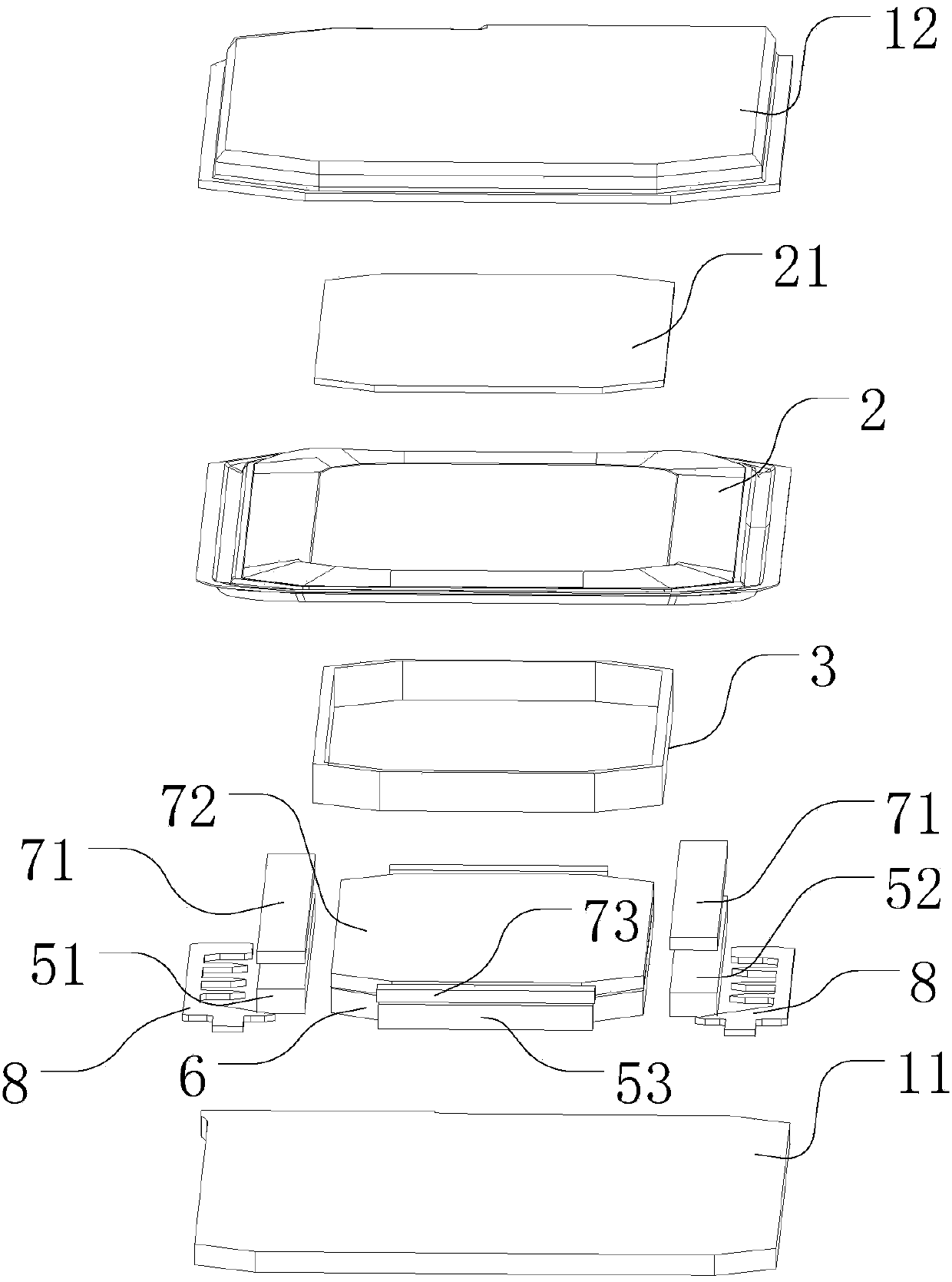

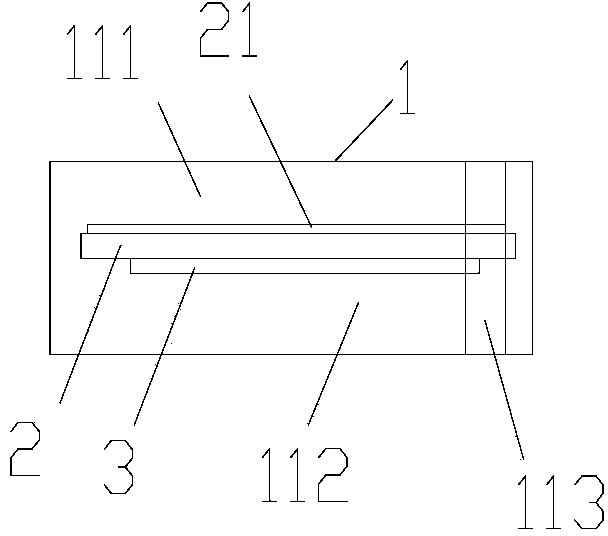

[0026] An embodiment of the present invention provides an ultra-thin speaker-type heat sink, comprising: a heat conduction chamber, a vibrating diaphragm accommodated in the heat conduction chamber, a voice coil, and opposite sides of the voice coil that are perpendicular to the side and have opposite magnetic loops The magnetic device, the vibrating diaphragm divides the heat conduction chamber into two air chambers, the side walls of the two air chambers are provided with air holes, the voice coil and the vibrating diaphragm are fixed together, and the terminal of the voice coil extends out of the heat conduction chamber for receiving The input of alternating current, the magnetic device and the alternating current in the voice coil generate ampere force to drive the voice coil and the vibrating diaphragm to vibrate in the heat conduction chamber, which is used to discharge or inhale the gas in the two air chambers through the corresponding air holes.

[0027] Such as figure 1

Embodiment 2

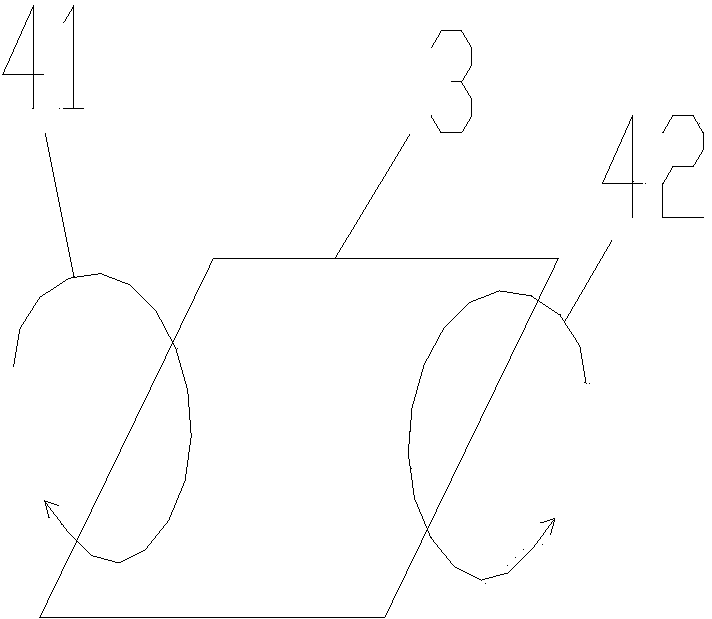

[0038] In order to further reduce the overall vibration of the vibrating heat sink, the embodiment of the present invention makes improvements on the basis of the above-mentioned embodiment 1, and provides a shock-absorbing ultra-thin heat sink, including symmetrically arranged on the center line as a whole A plurality of the above-mentioned ultra-thin speaker-type radiators, the ultra-thin speaker-type radiators on both sides of the symmetry axis have opposite vibration phases, and the plurality of ultra-thin speaker-type radiators are installed on a bracket.

[0039] Such as Figure 5 As shown, taking the shock-absorbing ultra-thin radiator composed of two ultra-thin speaker radiators as an example, the ultra-thin speaker radiator 10 and the ultra-thin speaker radiator 20 are arranged in an axisymmetric structure, and the bracket 30 has two A unit fixing frame is used to respectively fix the ultra-thin loudspeaker radiator 10 and the ultrathin loudspeaker radiator 20, that is,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap