Aero-engine high-pressure fuel and grease heat radiator

An aero-engine and radiator technology, which is applied in the direction of engine lubrication, engine components, machines/engines, etc., can solve the problems of heavy system weight, inconvenient maintenance, affecting installation, etc., to reduce system pipelines and reduce maintenance requirements. , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the claimed protection scope is not limited to the description.

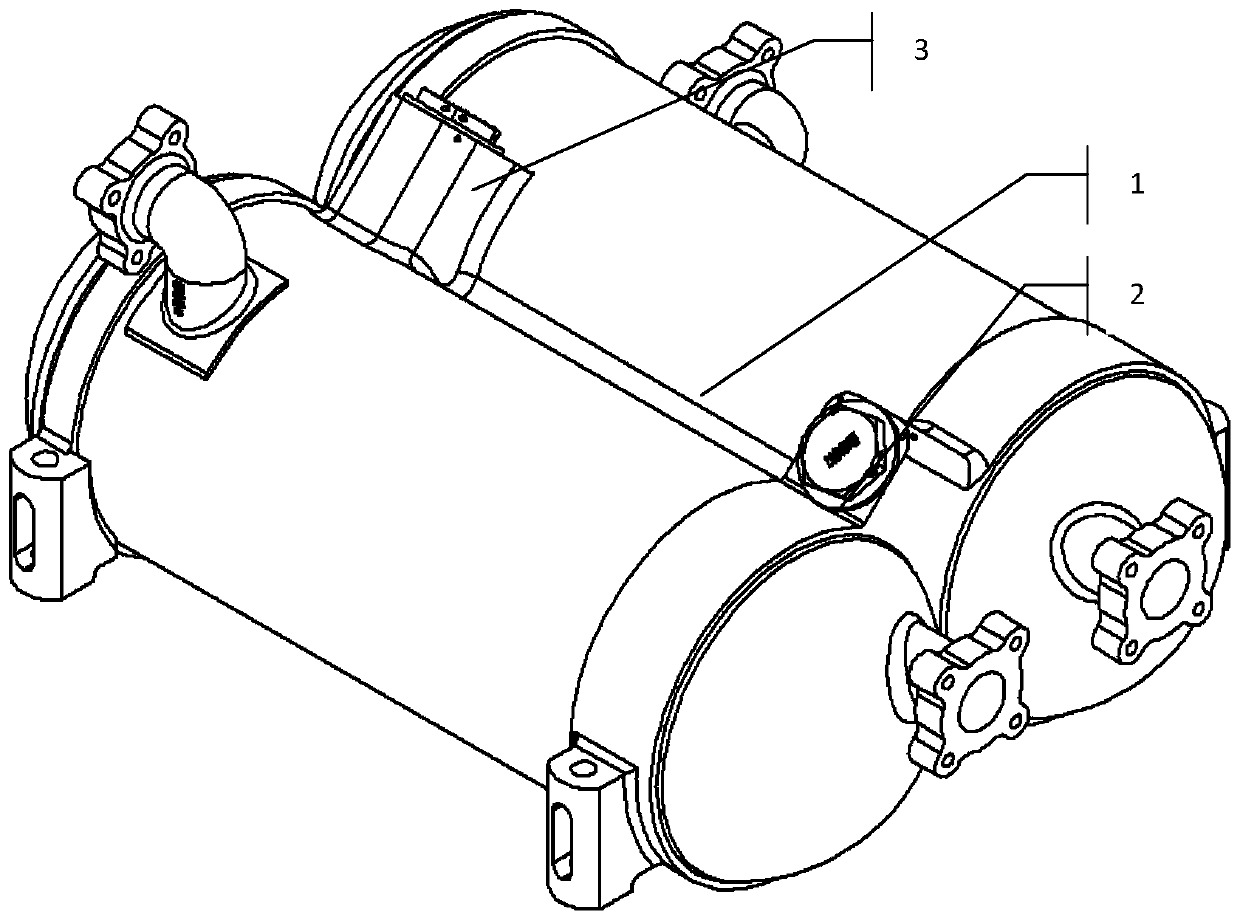

[0028] Such as figure 1 Shown is a structural diagram of a double-core structure high-pressure fuel oil radiator of the present invention. On the whole, the structure is mainly composed of a double-core body fuel oil radiator assembly 1, a fuel safety bypass valve 2, and oil The safety bypass valve 3 is composed of a fuel / lubricating oil safety valve that is assembled and connected with the double-core fuel and lubricating oil radiator assembly 1 by threads.

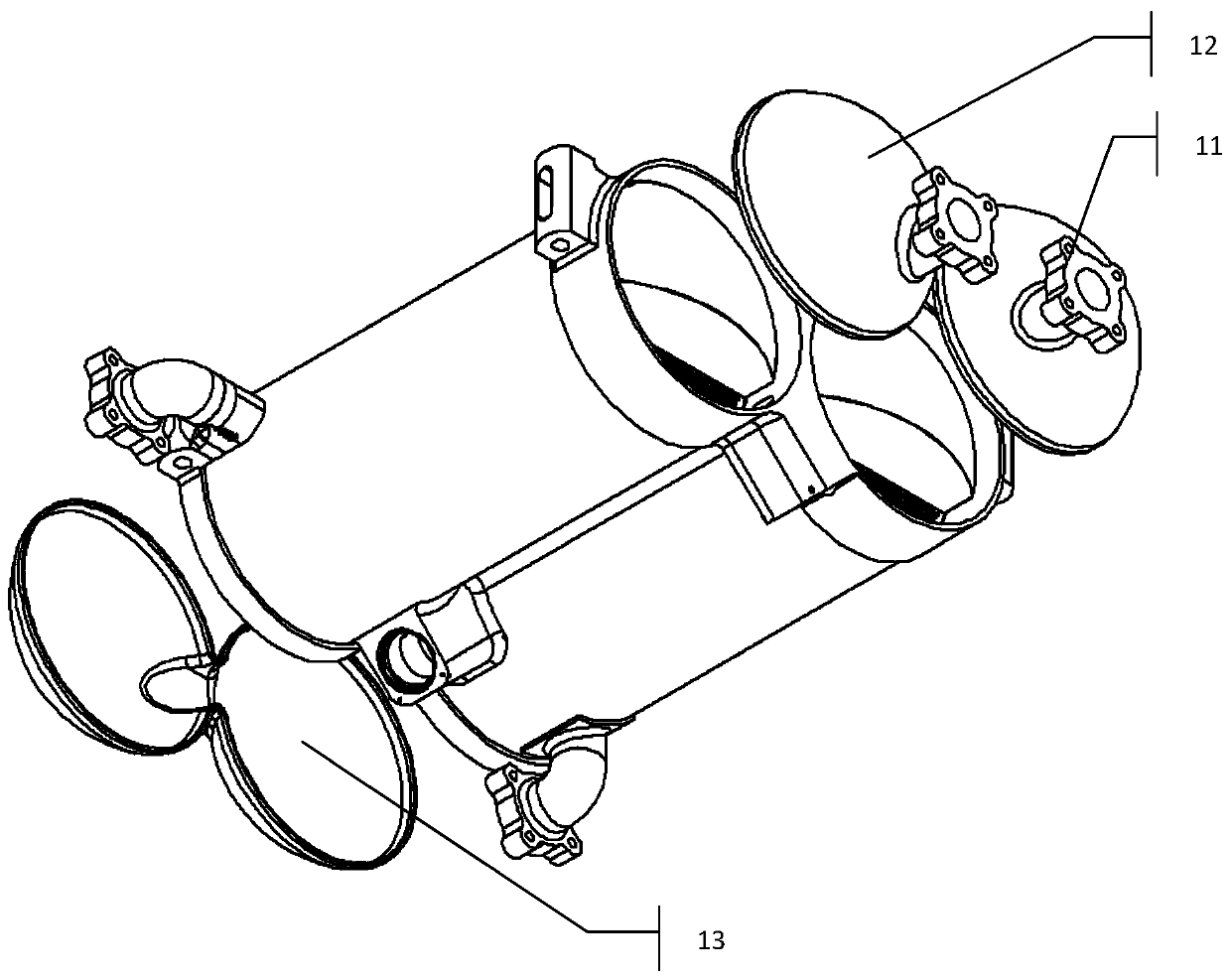

[0029] Such as figure 2 As shown, it is a schematic diagram of a double-core fuel oil radiator assembly 1 in a high-pressure fuel oil radiator with a double-core structure of the present invention, which mainly consists of a double-core fuel oil radiator core 10, a fuel inlet ball Cover 11, fuel outlet spherical cover

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap