Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8 results about "Decarburization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Decarburization (or decarbonization) is the process opposite to carburization, namely the reduction of carbon content. The term is typically used in metallurgy, describing the reduction of the content of carbon in metals (usually steel). Decarburization occurs when the metal is heated to temperatures of 700 °C or above when carbon in the metal reacts with gases containing oxygen or hydrogen. The removal of carbon removes hard carbide phases resulting in a softening of the metal, primarily at the surfaces which are in contact with the decarburizing gas.

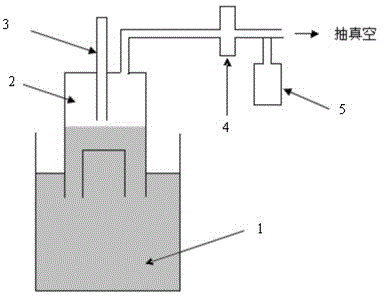

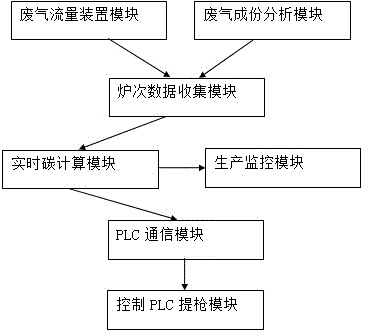

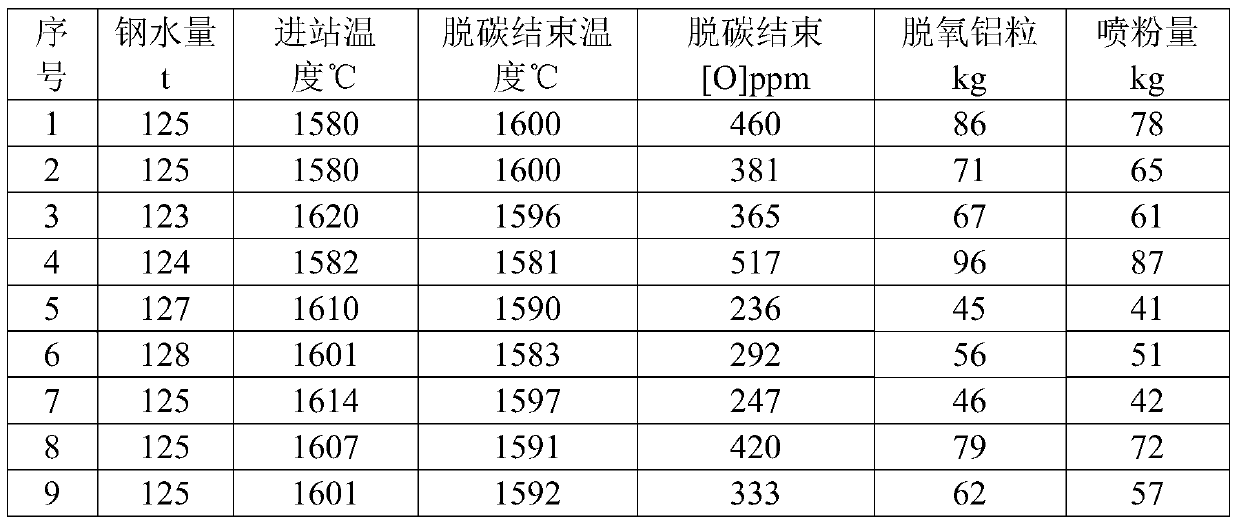

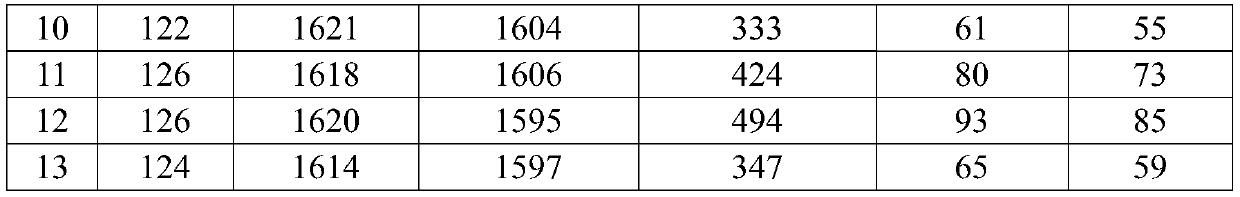

Mass spectrometer based RH dynamic decarbonization method and device

InactiveCN104131137ARealize automatic controlRealize stop blowingAutomatic controlRelevant information

Owner:NANJING MEISHAN METALLURGY DEV +2

Modification technology of aluminum deoxidization product of non-oriented silicon steel

InactiveCN110283962ADeoxidizationDecarburization

Owner:MAANSHAN IRON & STEEL CO LTD

Continuous spheroidizing annealing method for high-carbon chromium bearing steel round steel

PendingCN114107626AImprove uniformityPromote the transformation of globularizationBrinellingHeat conservation

Owner:LIANFENG STEEL (ZHANGJIAGANG) CO LTD

Bearing steel pipe inspection quality control method for cold rolling and expanding bearing

ActiveCN113088639AQuality improvementExtended service lifeFurnace typesTesting metalsBrinellingCarbide

The invention discloses a bearing steel pipe inspection quality control method for a cold rolling and expanding bearing. In the production process of a bearing steel pipe, pipe blank factory inspection, spheroidizing annealing state capillary pipe inspection and stress relief annealing state finished pipe inspection are sequentially carried out; stress relief annealing state finished pipe inspection includes hardness inspection, microscopic structure inspection, carbide non-uniformity inspection and decarburized layer inspection; during hardness inspection, the Brinell hardness is 179-190 HBW, and the grade is 2-3 according to the fifth grade diagram evaluation in the appendix A of GB / T 18254-2016 during microscopic structure inspection. The bearing steel pipe is subjected to quality control through the method, the surface of the bearing produced through cold rolling and expansion is free of cracks, the structure uniformity is high, thus the quality of the bearing is improved, and the service life of the bearing is prolonged.

Owner:JIANGXI HONGRUIMA STEEL PIPE

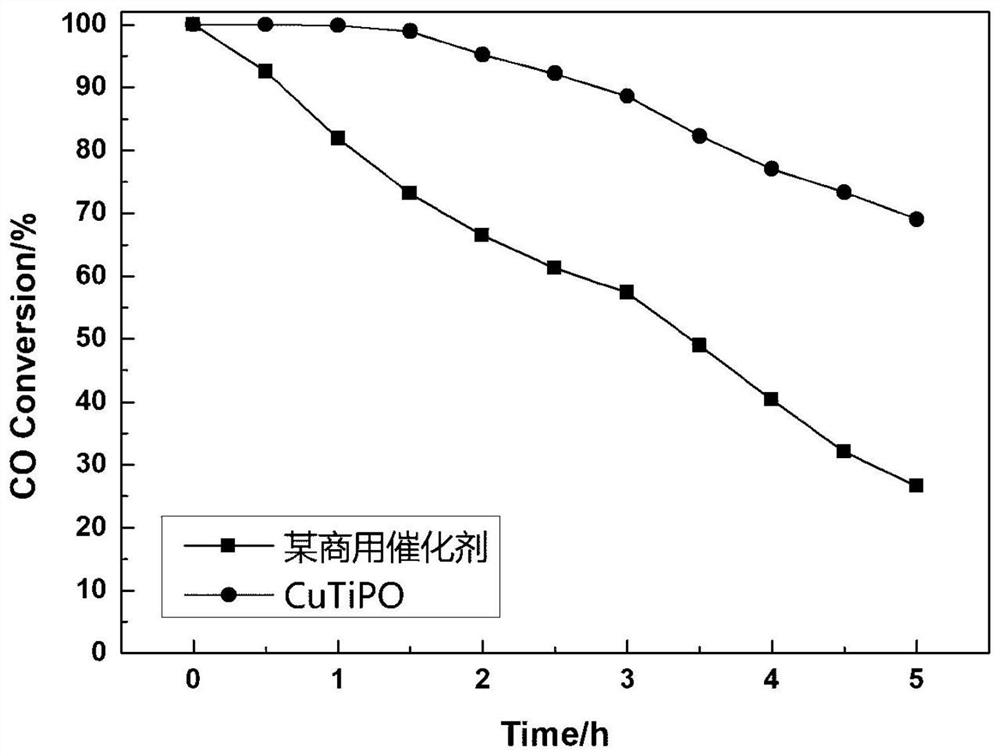

Preparation process of improved sulfur-resistant sintering flue gas decarburization catalyst

PendingCN114289041AIncrease the number ofEnhanced Surface AcidityPhysical/chemical process catalystsDispersed particle separationPtru catalystFlue gas

Owner:ANHUI XINCHUANG ENERGY SAVING & ENVIRONMENTAL PROTECTION SCI & TECH +1

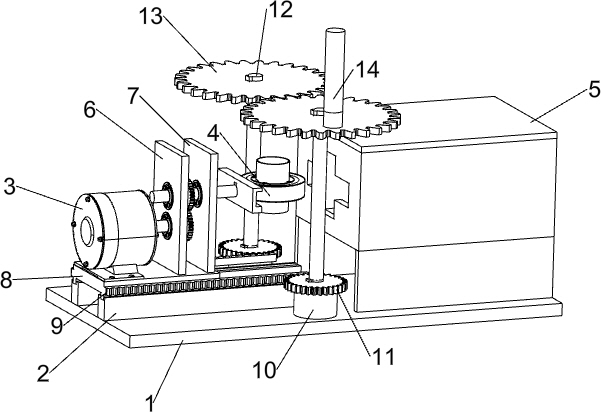

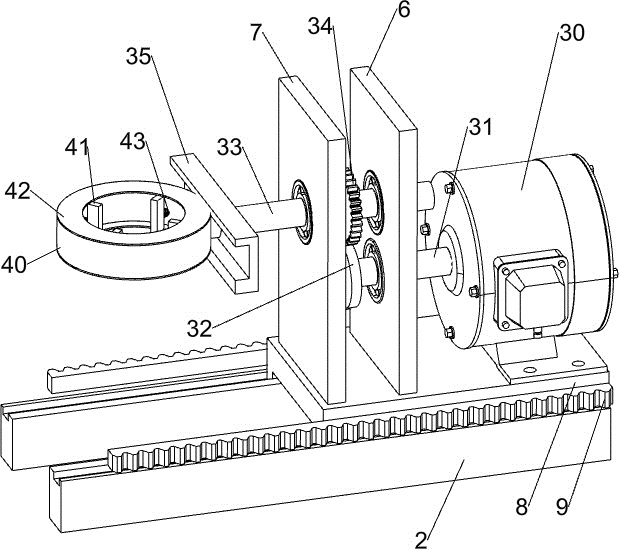

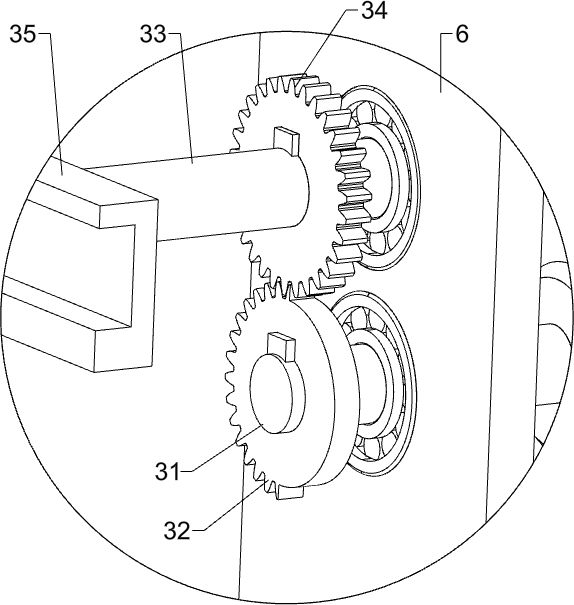

Uniform heating equipment for cylindrical workpiece

PendingCN112247065AEvenly heatedAvoid the effects of oxidative decarburizationHeating/cooling devicesCrankEngineering

Owner:欧阳建福

On-line quenching and tempering technology of seamless steel tube

InactiveCN103276180AResistant to bendingImpact resistantFurnace typesHeat treatment furnacesQuenchingMachining

The invention relates to an on-line quenching and tempering technology of a seamless steel tube. The technology comprises the steps as follows: (1), quenching: the temperature quickly rises to 900 DEG C to 920 DEG C at a speed of 25 DEG C-35 DEG C / s, then the temperature is quickly decreased to about 310 DEG C at a speed of 200 DEGC-220 DEG C / s by primary spraying, and secondary spraying is performed until the temperature is lower than 80 DEG C; and (2), tempering: the temperature rising speed is 20 DEG C-30 DEG C / s, the temperature rises to a range from 620 DEG C to 640 DEG C, and air cooling is performed after heat preservation. The on-line quenching and tempering technology of the seamless steel tube can reduce harmful elements and improve purity of steel, so that scrapping caused by harmful defects such as folding, cracks, separation layers, surface decarburization and the like generated in hot and cold machining of a pipe material can be avoided.

Owner:JIAXING XINJIYUAN STEEL TUBE MFG CO LTD

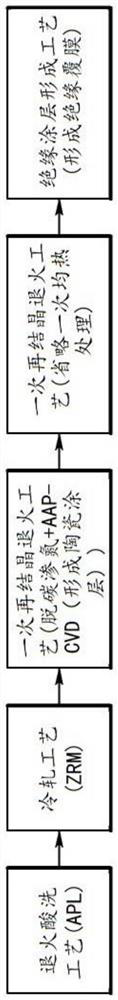

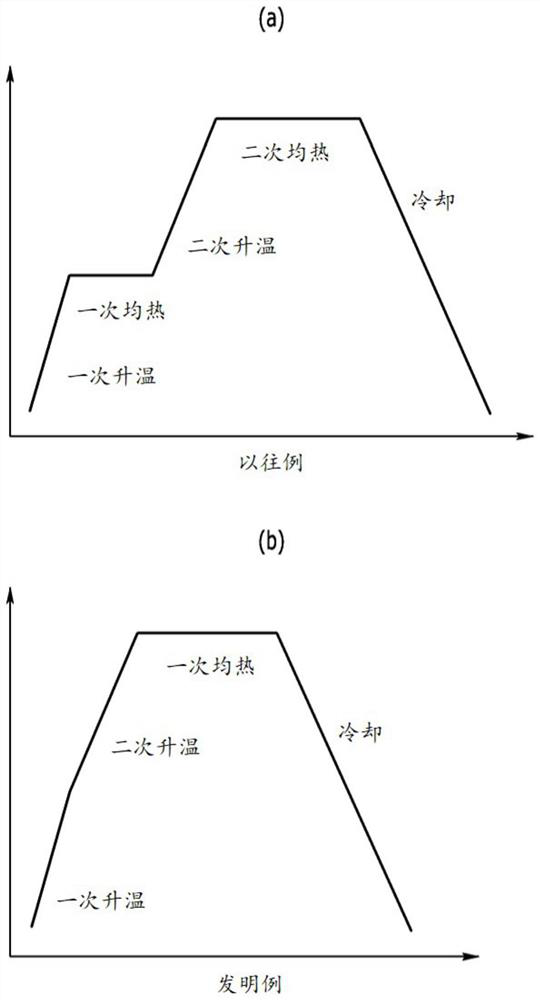

Grain-oriented electrical steel plate and preparation method thereof

PendingCN114867874AReduce iron lossGood insulation propertiesFurnace typesChemical vapor deposition coatingElectrical steelCeramic coating

Owner:POHANG IRON & STEEL CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap