Modification technology of aluminum deoxidization product of non-oriented silicon steel

A silicon steel aluminum product technology, applied in the technical field of non-oriented silicon steel aluminum deoxidation product denaturation, can solve the problems of continuous casting nozzle flocculation, etc., achieve the effect of reducing product surface inclusions, reducing product surface inclusion defects, and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

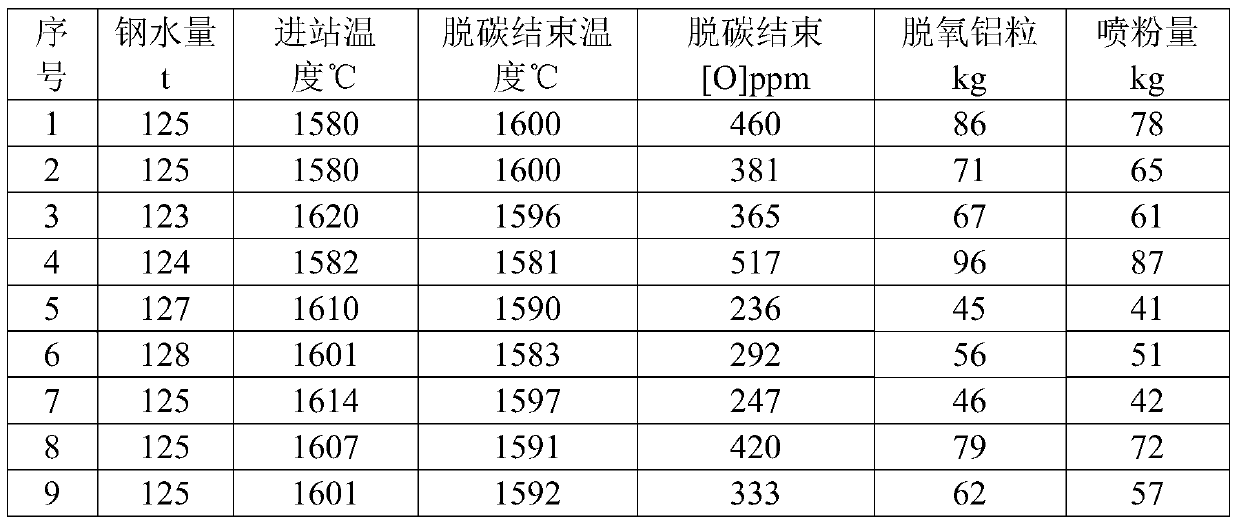

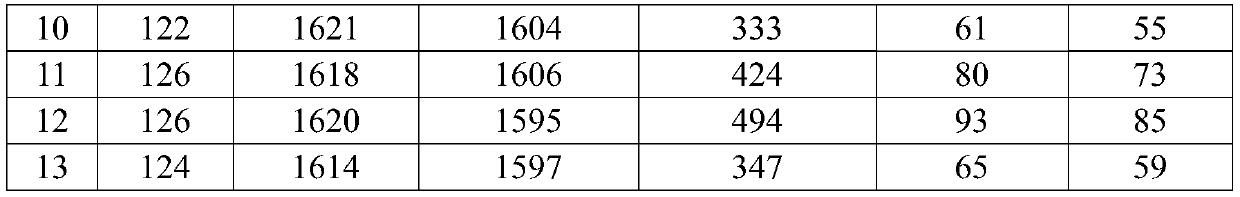

[0030] The 120-ton converter-120-ton RH-CSP thin slab continuous casting process is implemented on W800 for the production of non-oriented silicon steel. The 13 continuous casting furnaces are planned to stop pouring. The total pouring time is about 690 minutes. The stopper curve is stable (the starting rod position is about 67mm, The position of the stop casting rod is about 63mm), the pouring is normal, and there is basically no floc in the inner cavity of the nozzle after casting. The main parameters of RH refining of molten steel for each heat are shown in Table 1.

[0031] Table 1 Main parameters of RH refining of molten steel in each heat

[0032]

[0033]

[0034] After specific implementation certification, the process of the present invention can solve the problem of flocculation at the nozzle of continuous casting, realize multi-furnace continuous casting and reduce product surface inclusion defects. The number of continuous casting furnaces reaches more than 12 f

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap