Image Sensor with Color Filters and Method of Manufacturing the Same

a color filter and image sensor technology, applied in the field of image sensors, can solve the problems of deteriorating uniformity of light with a wavelength range transmitted through the microlenses, and achieve the effect of improving a sensitivity of the image sensor and reducing a distan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015]Hereinafter, the present will be described in detail with reference to accompanying drawings.

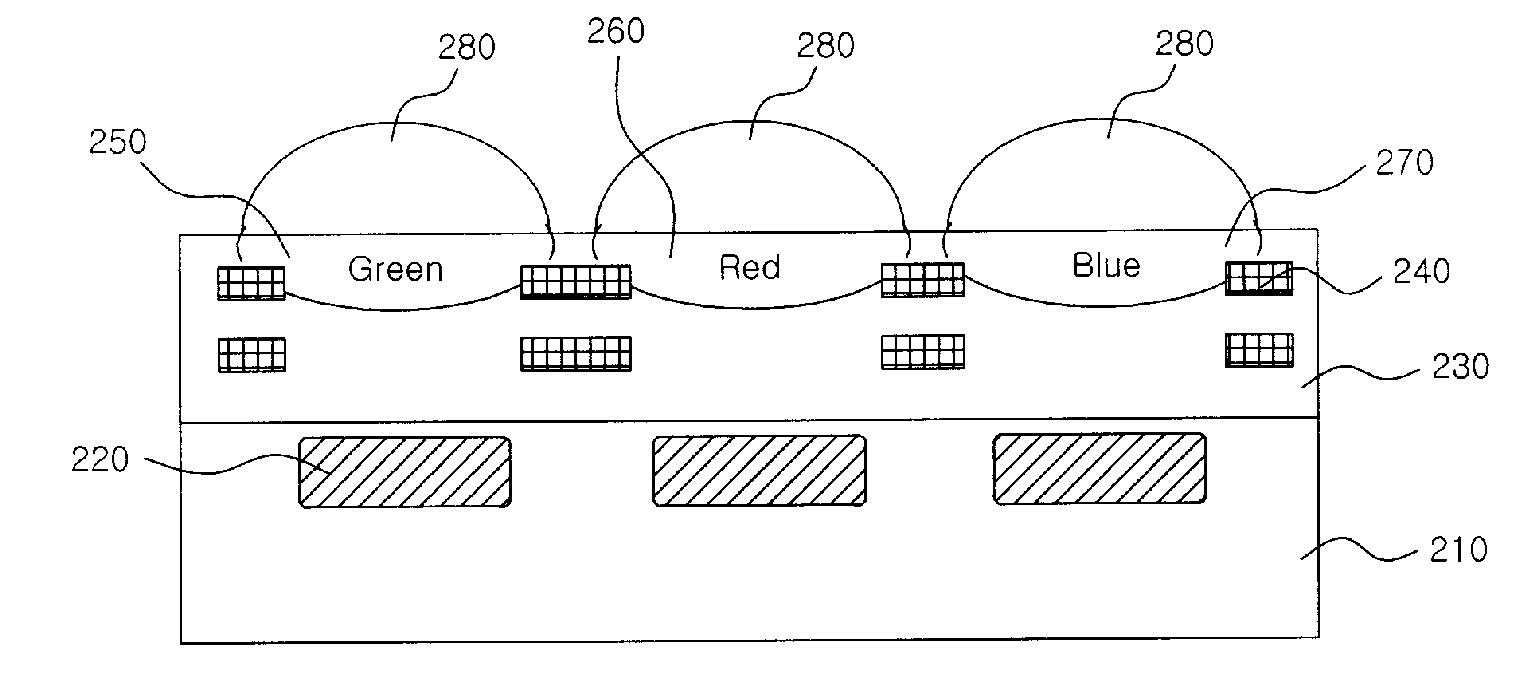

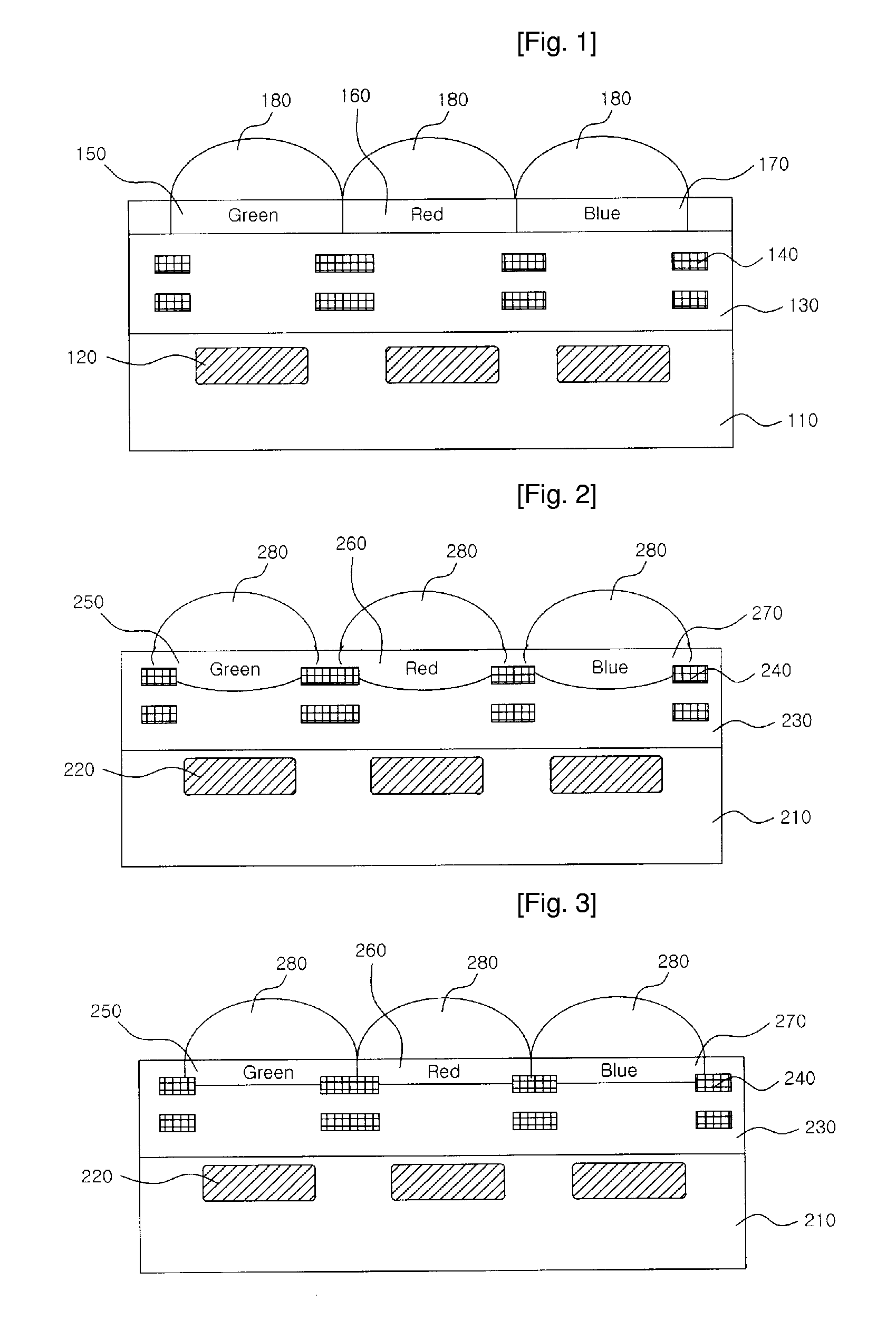

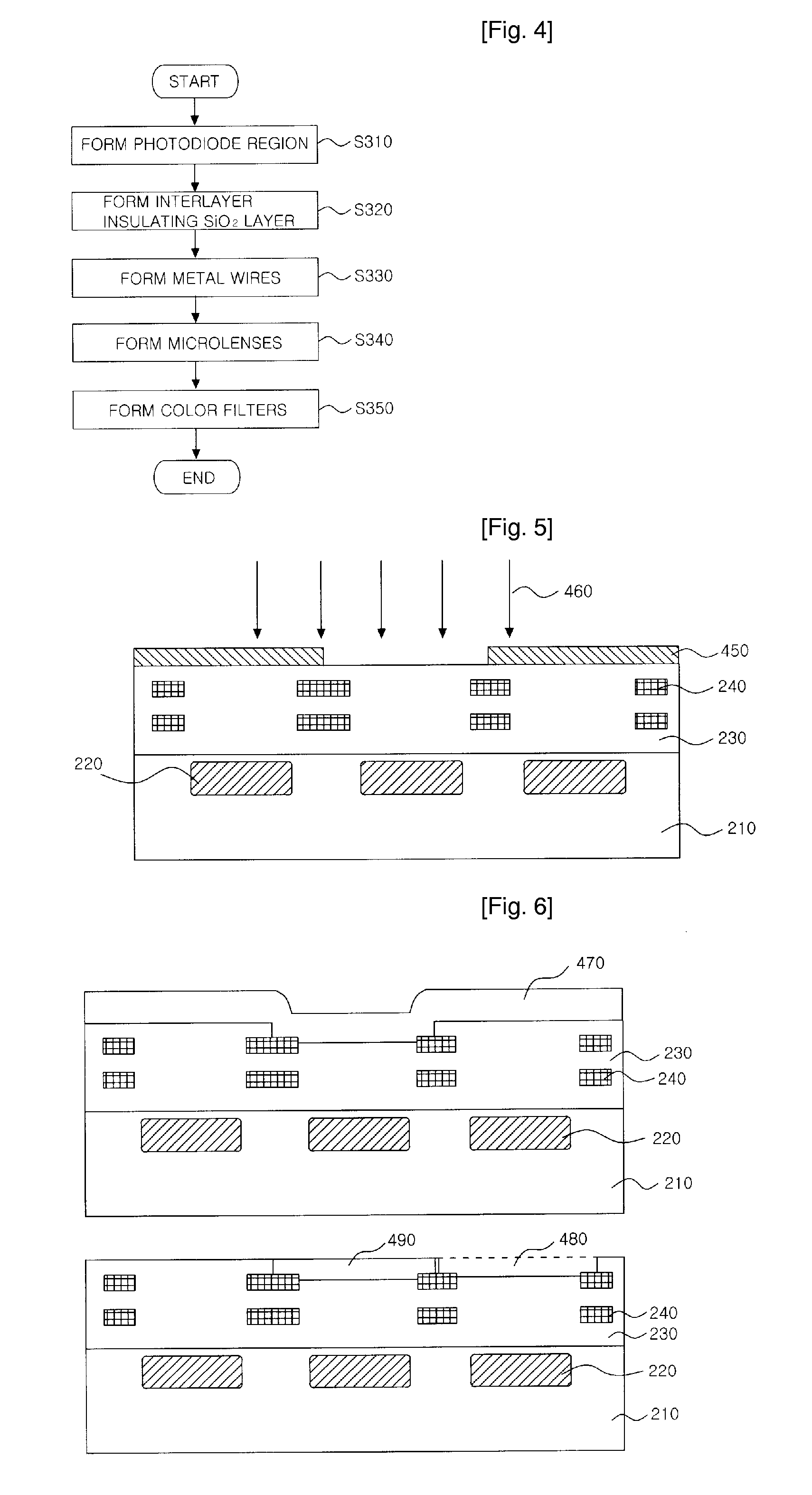

[0016]FIG. 2 is a cross sectional view illustrating an image sensor with color filters according to an embodiment of the present invention. FIG. 3 is a cross sectional view illustrating an image sensor with color filters according to another embodiment of the present invention.

[0017]Referring to FIGS. 2 and 3, the image sensor with color filters according to the embodiment of the present invention includes a silicon substrate 210, a plurality of photodiodes 220 that is formed in the silicon substrate 210, an interlayer insulating SiO2 layer 230 that is formed on the silicon substrate 210, metal wires 240 that is formed in the interlayer insulating SiO2 layer, a plurality of color filters 250, 260, and 270 of green, red, and blue that are formed in the interlayer insulating SiO2 layer from the surface of the interlayer insulating SiO2 layer to a predetermined depth, and a plurality of micr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap