Safe flexible package lithium ion battery tab

A lithium-ion battery and flexible packaging technology, applied in the field of lithium-ion batteries, can solve problems such as external and internal thermal runaway, and achieve the effects of saving manufacturing costs, preventing further reactions, and controlling thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

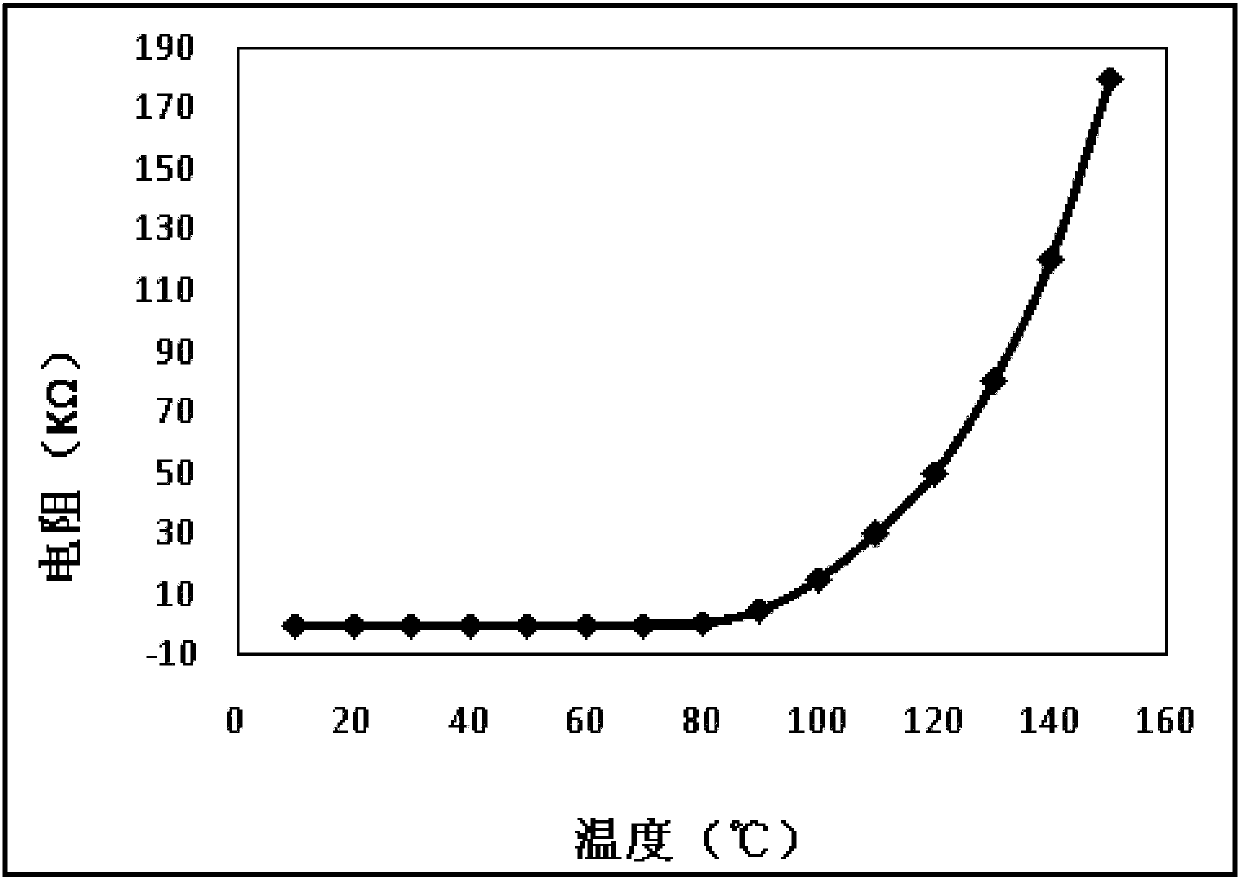

[0026] A safe soft-packaged lithium-ion battery lug includes a positive pole, a negative pole lug body, and a PTC coating coated on the surface of the positive and negative pole lug bodies.

[0027] The positive tab body is made of aluminum-based material, and the negative tab body is made of nickel-plated copper. The thickness of one side of the PTC coating is 4 microns, and it is formed by curing PTC slurry, and the PTC slurry includes a PTC matrix material, a dispersant, a binder and a solvent.

[0028] The PTC matrix material is BaTiO 3 . The dispersant is polyethylene glycol octylphenyl ether. The binder is polymethyl methacrylate. The solvent is N-methylpyrrolidone.

[0029] Among them, the ratio of PTC matrix material, dispersant, binder and solvent is 80:10:10:190.

[0030] The preparation method of the above-mentioned safe soft-packaged lithium-ion battery tabs is as follows:

[0031] Dissolve the binder in a solvent to prepare a binder glue, then mix the PTC matri

Embodiment 2

[0033] A safe soft-packaged lithium-ion battery lug includes a positive pole, a negative pole lug body, and a PTC coating coated on the surface of the positive and negative pole lug bodies.

[0034] The positive tab body is made of aluminum-based material, and the negative tab body is made of nickel-plated copper. The PTC coating has a thickness of 3 microns on one side and is formed by curing PTC slurry, and the PTC slurry includes a PTC matrix material, a dispersant, a binder and a solvent.

[0035] The PTC matrix material is BaPbO 3 . The dispersant is polyethylene oxide. The binder is cellulose acetate. The solvent is N-methylpyrrolidone.

[0036] Wherein, the ratio of PTC matrix material, dispersant, binder and solvent is 50:25:25:450.

[0037] The preparation method of the above-mentioned safe soft-packaged lithium-ion battery tabs is as follows:

[0038] Dissolve the binder in a solvent to prepare a binder glue, then mix the PTC matrix material, dispersant and binder

Embodiment 3

[0040] A safe soft-packaged lithium-ion battery lug includes a positive pole, a negative pole lug body, and a PTC coating coated on the surface of the positive and negative pole lug bodies.

[0041] The positive tab body is made of aluminum-based material, and the negative tab body is made of nickel-plated copper. The PTC coating has a thickness of 5 microns on one side and is formed by curing PTC slurry, and the PTC slurry includes a PTC matrix material, a dispersant, a binder and a solvent.

[0042]The PTC matrix material is composed of equal mass BaTiO 3 , BaPbO 3 composition. The dispersant is polyacrylic acid. The binder is a mixture of polymethyl methacrylate, pullulan and carboxymethyl cellulose; the solvent is N-methylpyrrolidone.

[0043] Among them, the ratio of PTC matrix material, dispersant, binder and solvent is 90:1:9:180.

[0044] The preparation method of the above-mentioned safe soft-packaged lithium-ion battery tabs is as follows:

[0045] Dissolve the bi

PUM

| Property | Measurement | Unit |

|---|---|---|

| Single side thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap