Anti-spatter laser die-cutting device and method

A laser die-cutting and anti-splash technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of incomplete dust prevention, unsatisfactory dust removal effect, and inability to achieve sealing, so as to ensure cutting efficiency and cutting quality, dust-proof effect, easy to replace the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings.

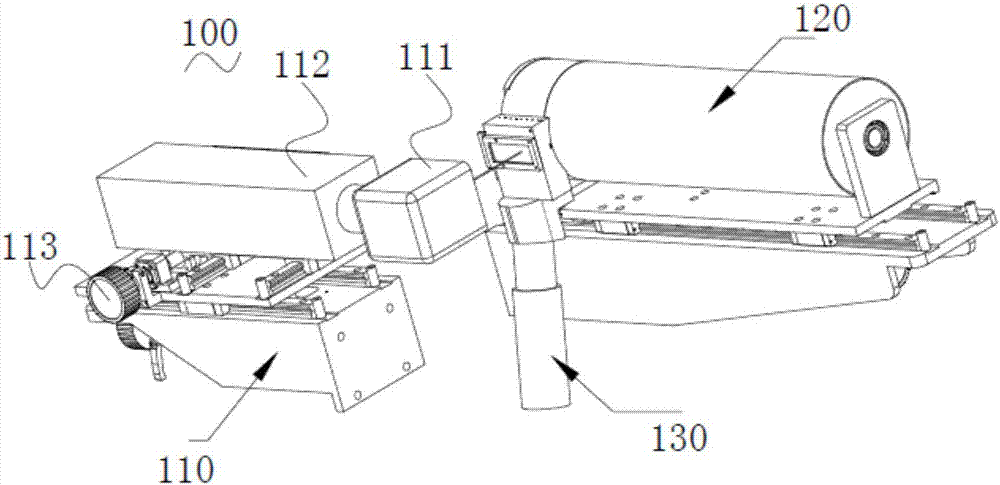

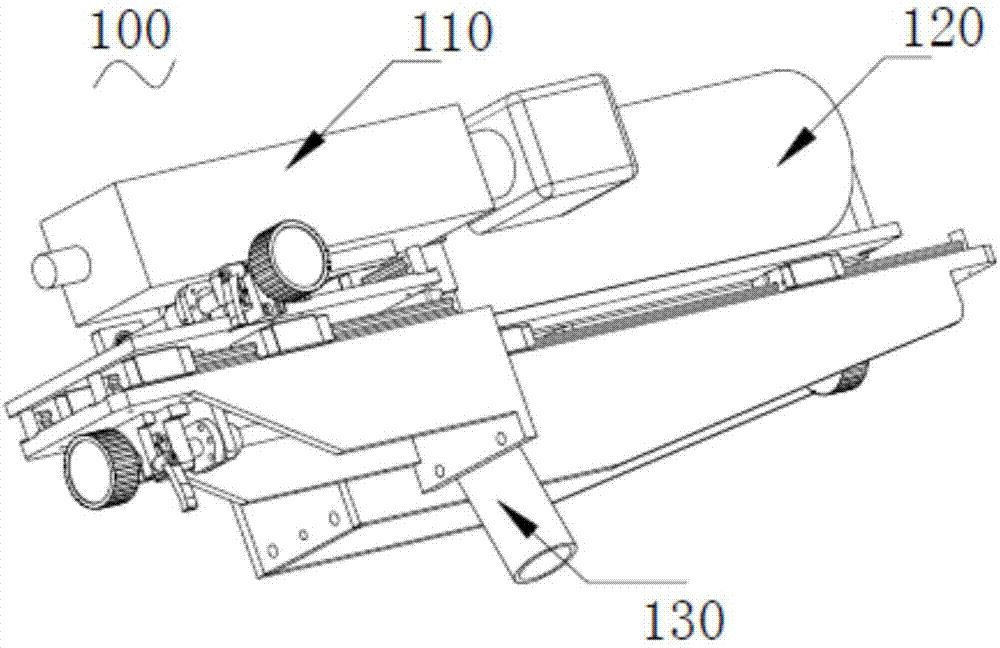

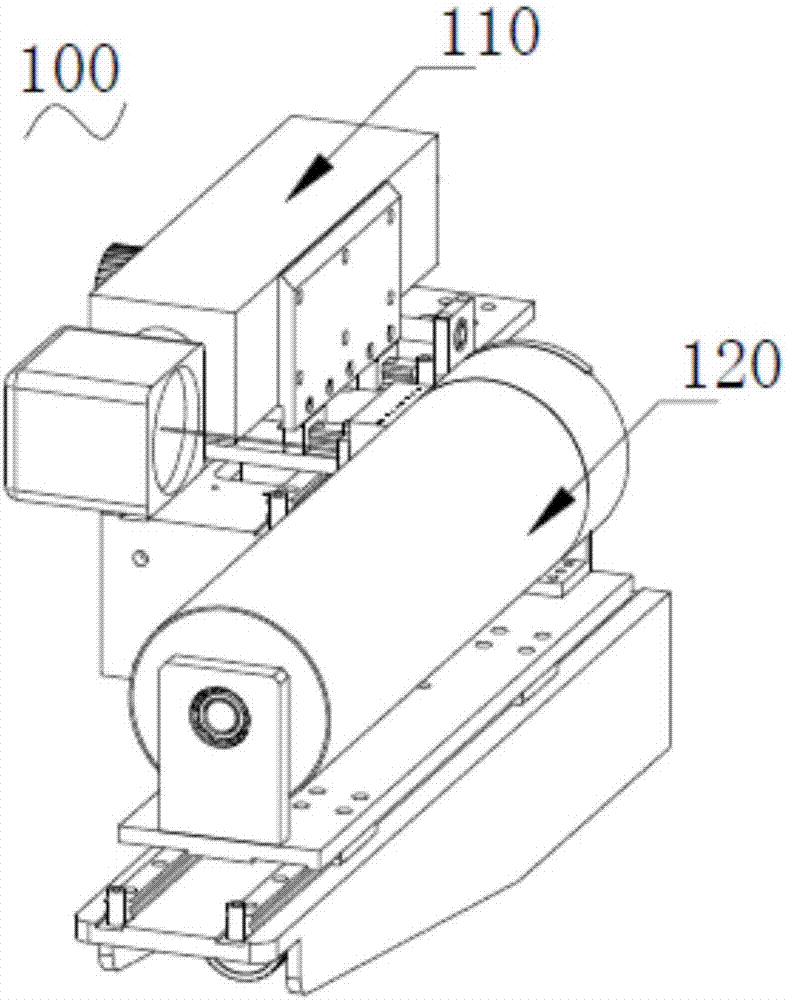

[0036] Such as Figure 1 ~ Figure 3 As shown, they are perspective views of different viewing angles of the anti-splash laser die-cutting device of the present invention.

[0037] The anti-splash laser die-cutting device 100 includes a laser cutting unit 110, a pole piece conveying roller 120 corresponding to the laser cutting unit 110, a dustproof unit 130 installed between the pole piece conveying roller 120 and the laser cutting unit 110, and the laser cutting unit 110 includes a laser head 111, and the dust-proof unit 130 includes a glass block 131 that is arranged facing the laser head 111 and located between the laser head 111 and the pole piece conveying roller 120 for laser light to pass through and to prevent dust from passing through. The laser cutting unit 110 emits laser light to die-cut the pole piece on the pole piece conveying roller 120, and the dust gene

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap