Stator assembly and axial magnetic field motor

A stator and component technology, applied in the direction of electric components, magnetic circuits, electrical components, etc., can solve the problems of motor heating, loss, and complex operating conditions of automobile drive motors, so as to reduce tooth harmonics, improve production efficiency, and facilitate The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The core of the invention is to provide a stator assembly and an axial field motor to improve the production efficiency of the motor.

[0023] In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

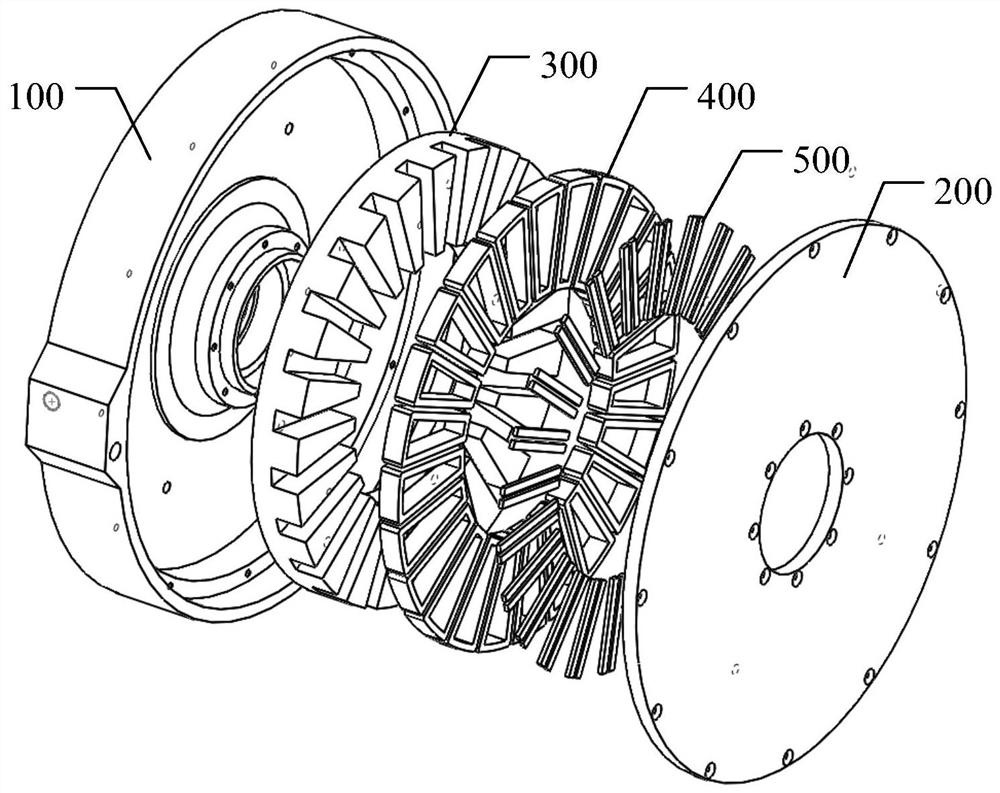

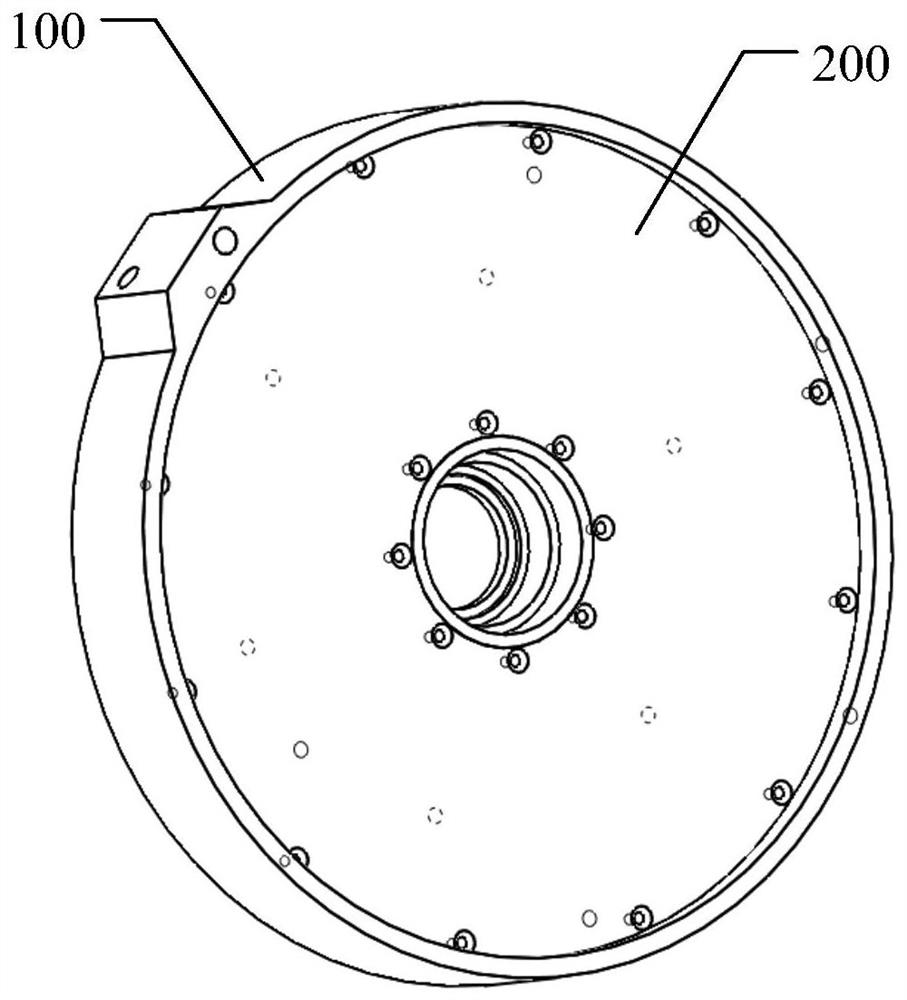

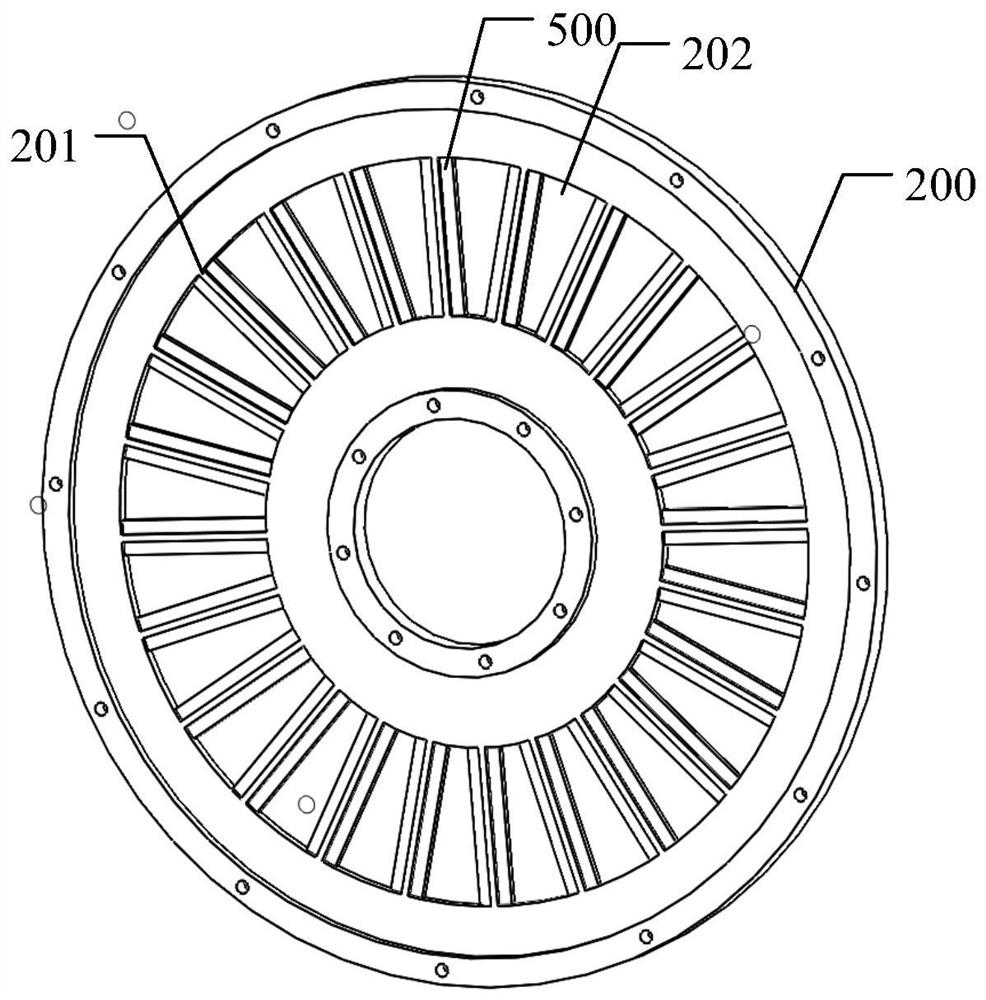

[0024] see Figure 1 to Figure 4 , the stator assembly in the embodiment of the present invention includes:

[0025] Housing 100 , stator core 300 , coil 400 , pole shoe 500 and stator cover 200 , wherein stator core 300 , coil 400 and pole shoe 500 are arranged in the space enclosed by housing 100 and stator cover 200 The coil 400 is arranged in the open slot 302 of the stator core 300; the pole shoe 500 is fixed on the stator cover plate 200, and when the stator cover plate 200 is docked with the housing 100, the pole shoe 500 can be arra

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap