Laminated laminated stator and manufacturing method thereof

A technology of interlocking and stator, which is applied in the manufacture of laminated interlocking stator and the field of laminated interlocking stator, can solve the problems of difficulty in reducing product cost, small winding operation space, and high cost of winding process, and achieves high assembly work efficiency. , The effect of reducing the winding process requirements and easy implementation of assembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

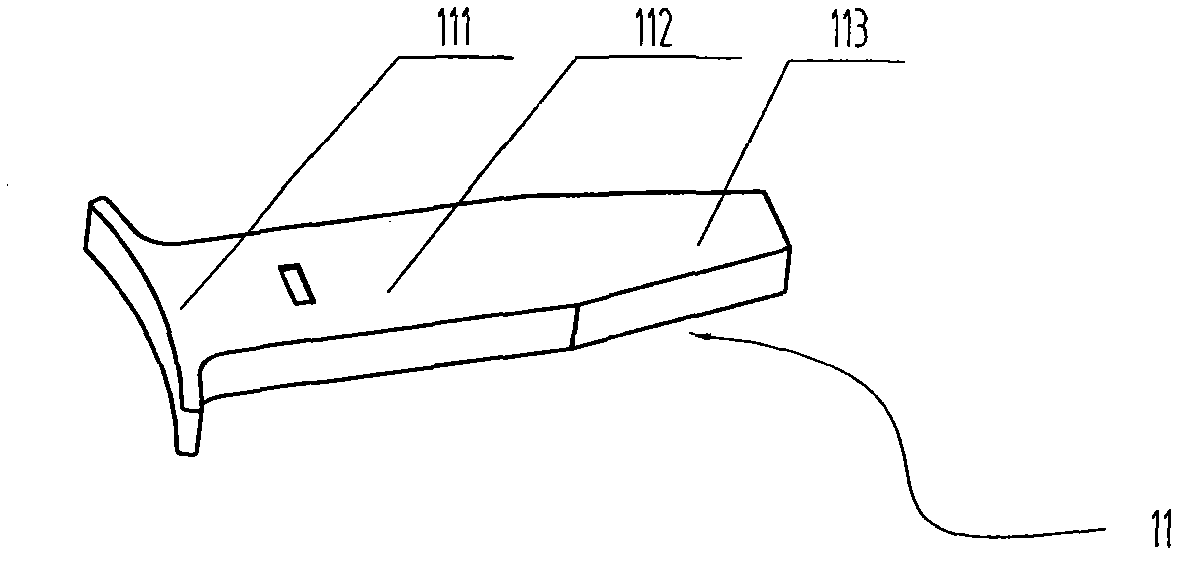

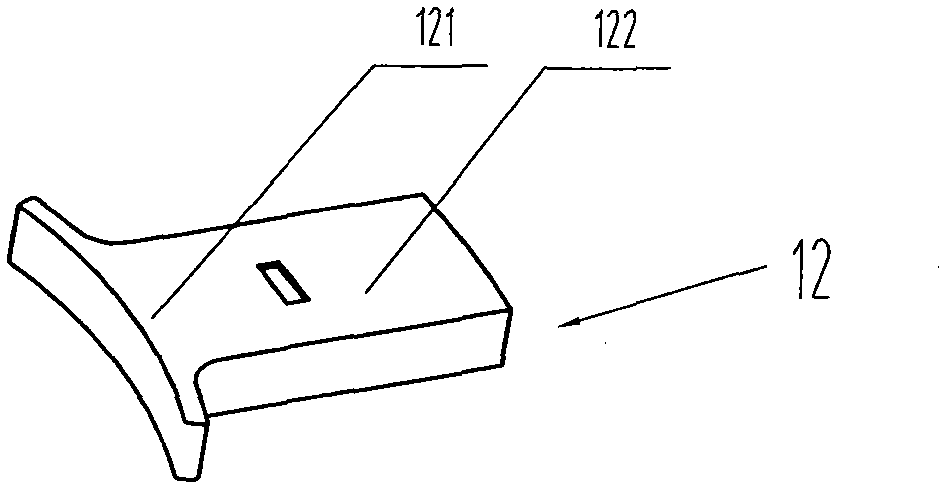

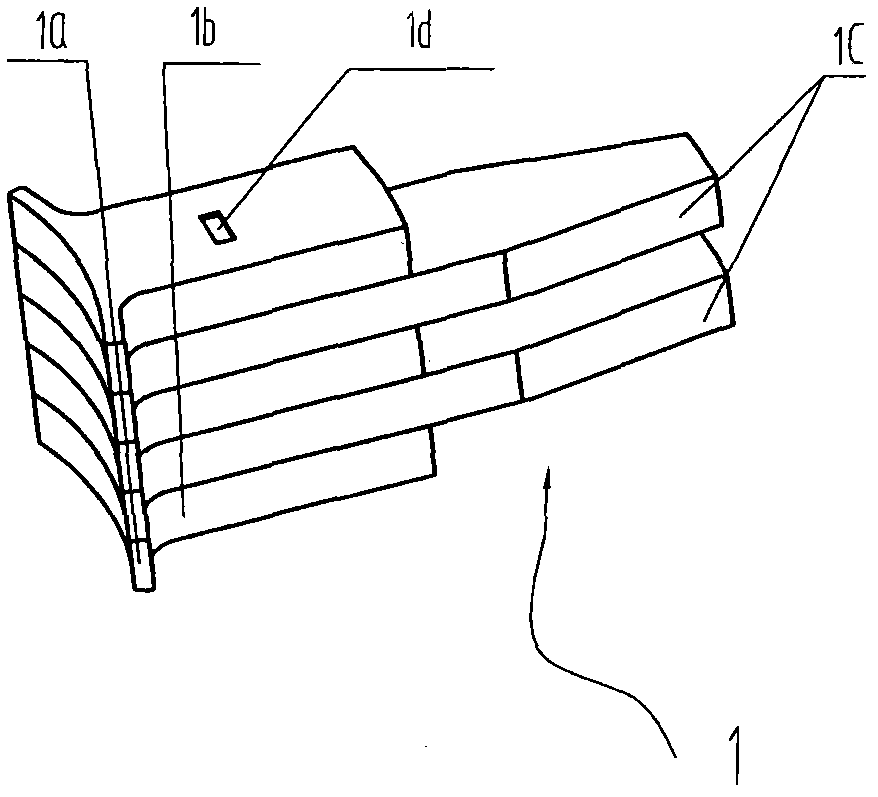

[0038] see figure 1 and figure 2 As shown, the long pole shoe punching piece 11 is T-shaped, and it is a single whole made up of the boot crown 111, the boot body 112 and the boot foot 113. The far end of the boot foot 113 is pointed, while the short pole shoe punching piece 12 is a single whole consisting of a boot crown 121 and a boot body 122, wherein the long pole shoe punch 11 and the short pole shoe punch 12 have the same thickness, and the shape and size of the boot crown 111 and the boot crown 121 are Similarly, the boot body 112 and the boot body 122 have the same width. exist image 3 Among them, the pole shoe module 1 is composed of a shoe crown part 1a, a shoe body part 1b and a shoe foot part 1c. As an example, the pole shoe module 1 is stacked alternately with three short pole shoe punches 12 and two long pole shoe punches 11, riveted and fixed together, and then fixed to each other by the rivet 1d provided on the shoe body 1b. It can be seen that the shoe body

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap