Cutting die processing device and cutting die automatic processing technology

A processing device and automatic processing technology, applied in cutting tools, household utensils, applications, etc., can solve the problems of time-consuming and affecting the machining accuracy of cutting dies, so as to save the time of manual auxiliary processing, shorten the production cycle, and increase the processing speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

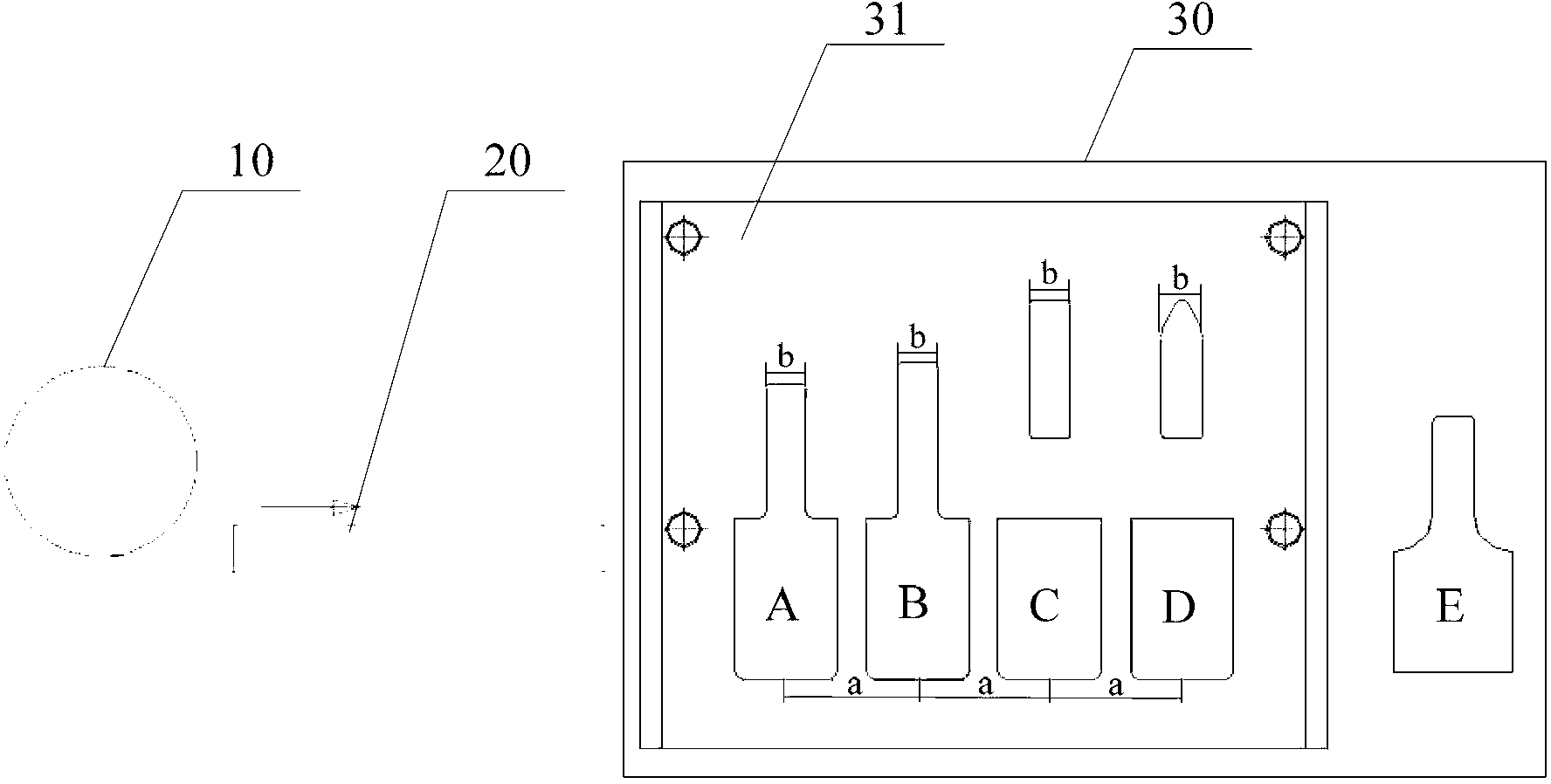

[0042] Such as figure 1 as shown, figure 1 It is a schematic structural view of the machete machine where the knife mold processing device of the preferred embodiment of the present invention is located; the machete machine includes a raw material tray 10, a feeding device 20 and a knife mold processing device 30 arranged in sequence along the conveying direction of the knife material, wherein :

[0043] The raw material tray 10 is used to provide cutting materials, and the feeding device 20 is used to provide cutting materials for the knife mold processing device 30. The knife mold processing device 30 is used to realize the flat cutting and olecranon cutting process of the front and rear ends of the knife mold.

[0044] Specifically, the knife die processing device 30 of this embodiment includes two bridge hole dies A and B, a flat cutting die C, an olecranon die D and a rear lower die E.

[0045] The two bridge hole dies A and B, as well as the flat cutting die C, the olecra

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap