Self-balancing type lathe fixture

A lathe fixture, self-balancing technology, applied in the direction of clamping, manufacturing tools, supports, etc., can solve the problem of simple and practical methods for lathe fixtures, achieve process man-hour balance, improve machining accuracy and surface quality, reduce Vibration and noise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

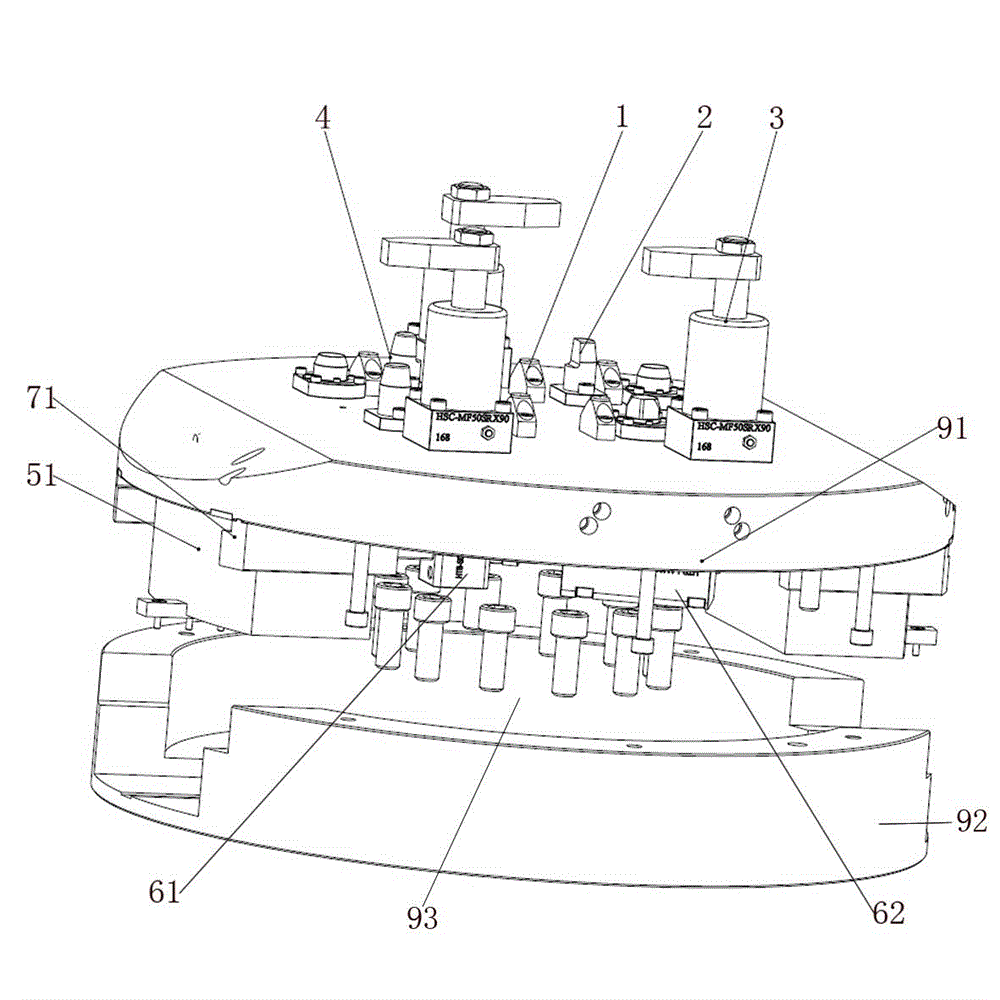

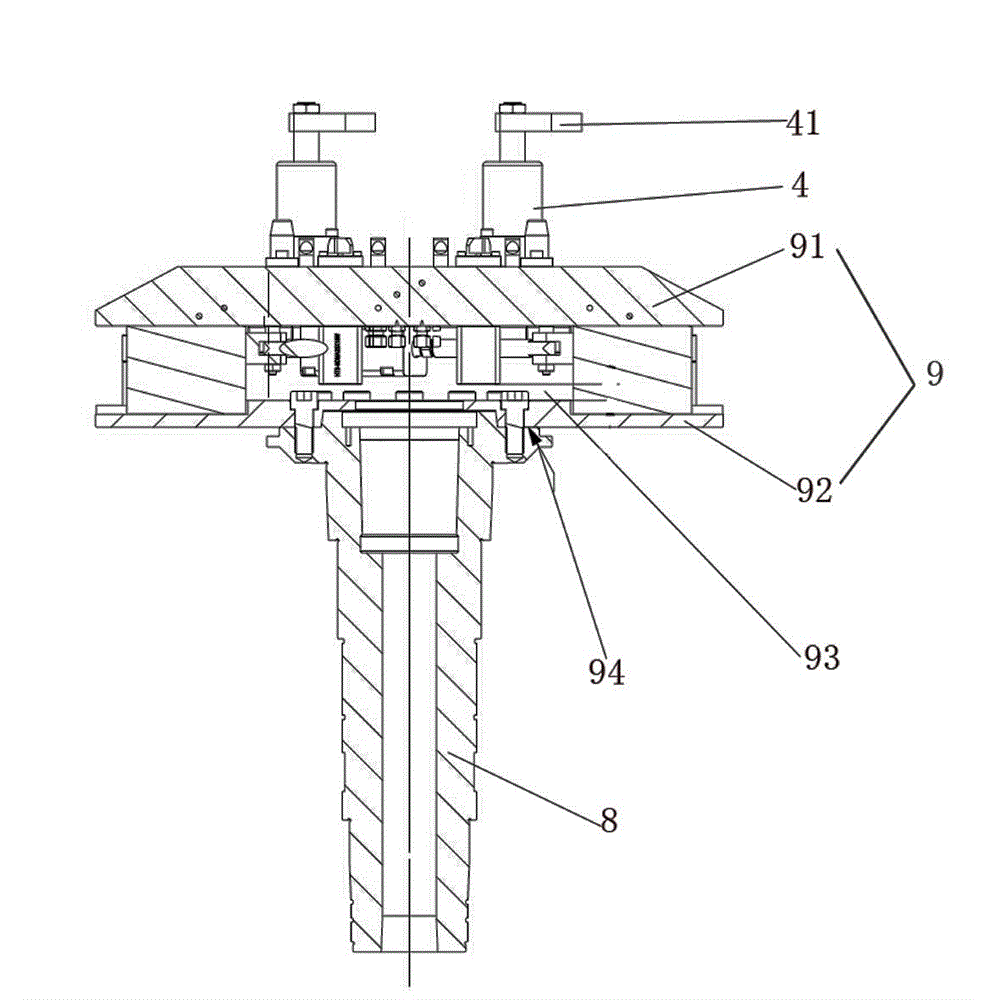

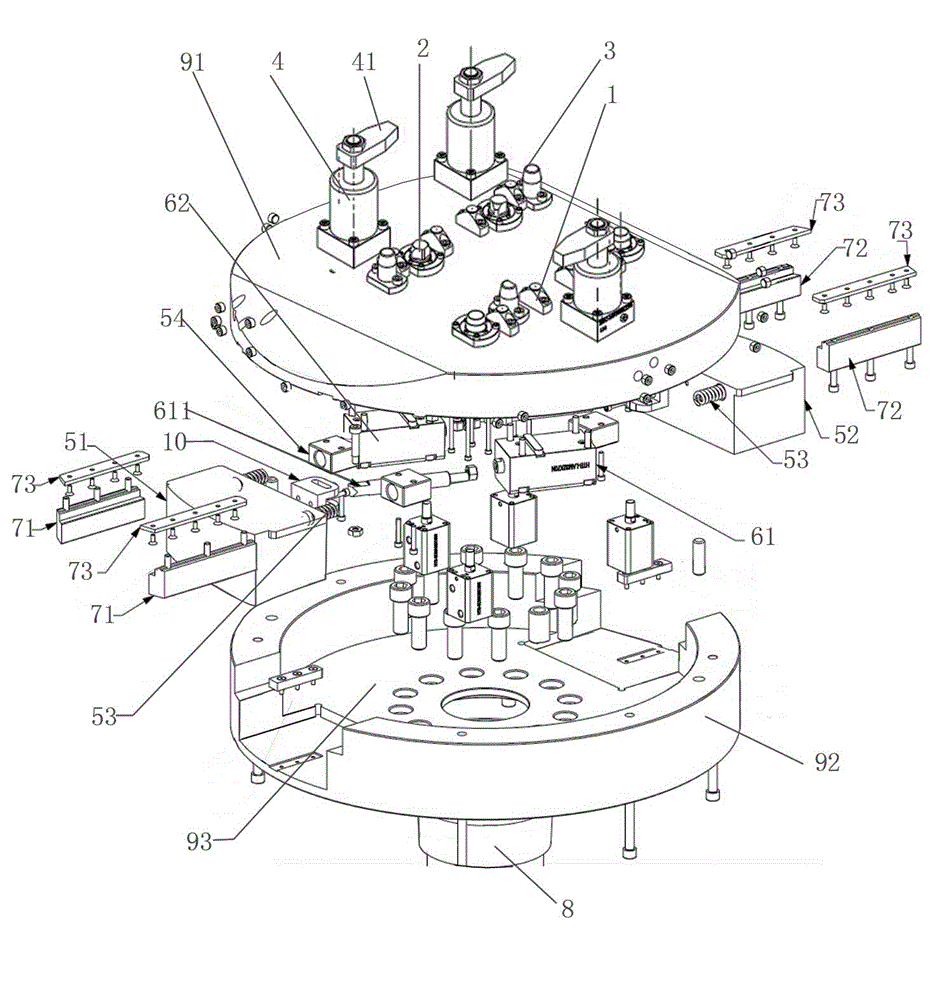

[0022] Example: see figure 1 —— image 3 .

[0023] The invention discloses a self-balancing lathe fixture, which includes a fixture table 9 connected with a machine tool spindle 8, a clamping piece is arranged on the top of the clamping piece 9, and the clamping piece includes a vertically arranged support Nail 1, fine positioning pin 2, pre-positioning pin 3 and corner hydraulic cylinder 4, the piston rod upper end of described corner hydraulic cylinder 4 is provided with horizontal pressure bar 41. The workpiece to be clamped is placed above the support nails 1 of the fixture table 9, and the three support nails 1 scattered above the fixture table 9 limit the three degrees of freedom of the workpiece. Two pre-positioning pins 3 realize the pre-positioning of the workpiece, and two precise positioning Pin 2 (one is a diamond pin) restricts three degrees of freedom of the workpiece, and the clamping of the workpiece is realized by driving the pressure rod 41 to move vertically

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap