Cleaning method of full-automatic cleaning device for oil drum

A fully automatic cleaning and oil drum technology, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve problems such as difficult to remove stain residue, affect recycling, and time-consuming and labor-intensive cleaning, etc., to achieve reduction Labor intensity, easy operation and use, and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

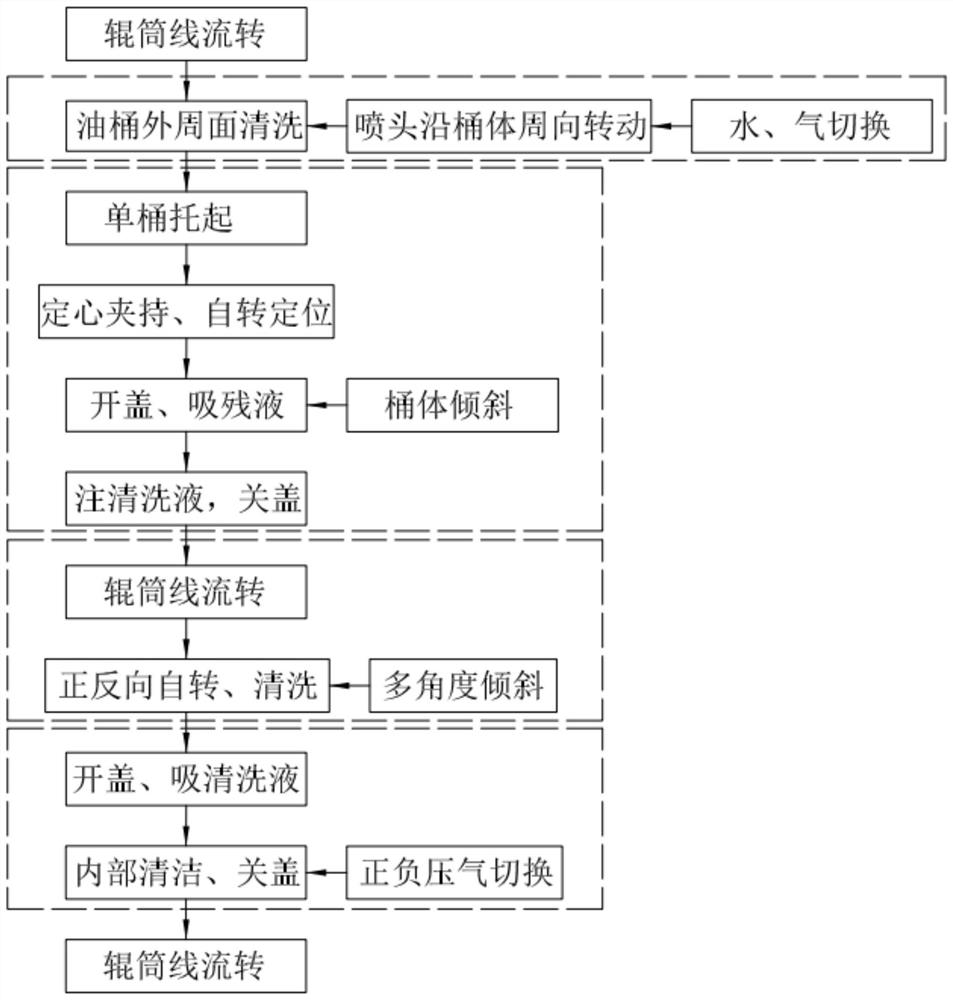

[0047] Such as figure 1 As shown, the cleaning method of the fully automatic cleaning device of the oil barrel of the present embodiment comprises the following steps:

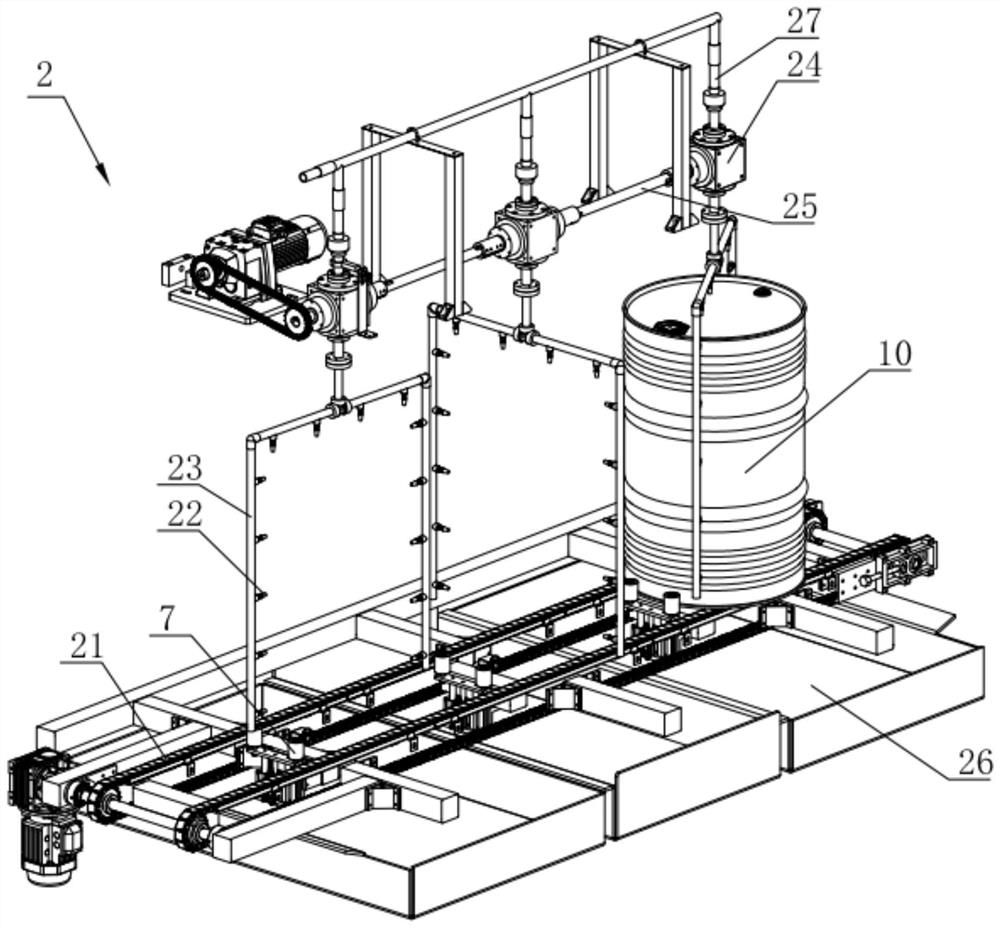

[0048] Step 1: The outer circumferential surface and top surface of the oil barrel 10 are sprayed by the nozzle 22. The nozzle 22 faces the oil barrel 10 and rotates with the axial direction of the oil barrel 10 as the center of the circle. carry out spray washing;

[0049] Step 2: The oil barrel 10 rotates around its own axial direction, and the sensor detects the position of the top oil barrel cover;

[0050] Step 3: Open the oil drum cover, the body of the oil drum 10 is inclined axially, and the residual liquid in the oil drum 10 is sucked away by the residual liquid injection mechanism 35;

[0051] The fourth step: through the control of the pipeline valve, inject the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap