Full-automatic Chinese chestnut opening and hulling machine

A fully automatic, shelling machine technology, applied in the fields of shelling, pod removal, food science, etc., can solve the problems of complex structure, low efficiency and large volume of shelling equipment, improve work efficiency and safety factor, and improve compatibility. Sex, the effect of extending the range of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

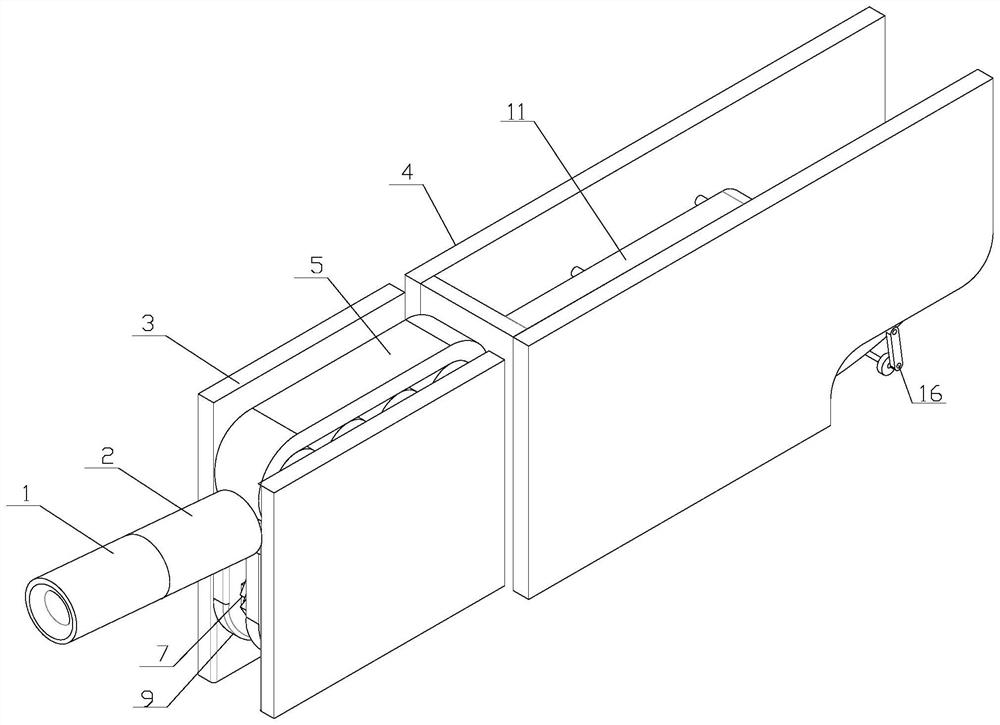

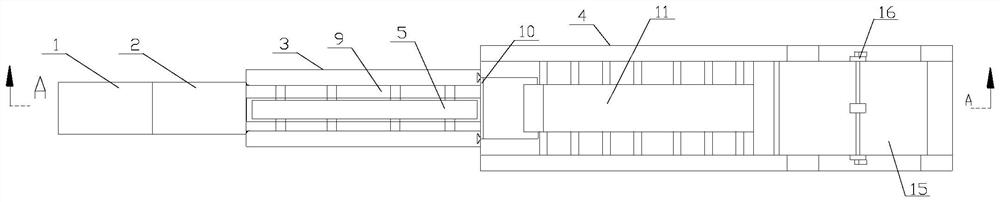

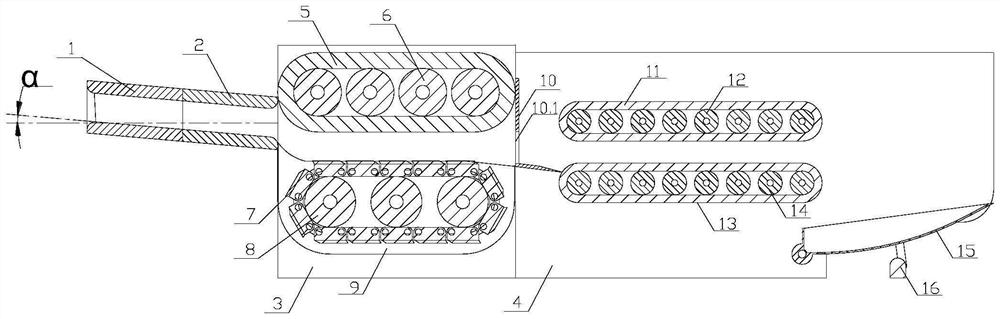

[0027] like Figure 1-4 As shown, a fully automatic chestnut opening and shelling machine includes a heating and cooling device, a conveying and cutting device, an extrusion shelling device, a shell kernel separation device and a control system;

[0028] The heating and cooling device includes a heating channel 1 and a condensation channel 2, both of which are cylindrical channels, one end of the heating channel 1 is connected to one end of the condensation channel 2, and the channels inside the two In communication, the heating channel 1 and the condensation channel 2 are arranged at an angle of 5-20° to the horizontal direction, and one end of the heating channel 1 is higher than the condensation channel 2;

[0029] The conveying and cutting device comprises two first support plates 3, a first silicone conveyor belt 5, several first driving wheels 6, a chain cutter 7, s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap