Automatic magnetic feeding device for brushless rotor

A magnetic device and rotor technology, applied in electromechanical devices, manufacturing stator/rotor bodies, electric components, etc., can solve the problems of demagnetization, demagnetization, low yield, etc., and achieve full automation and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

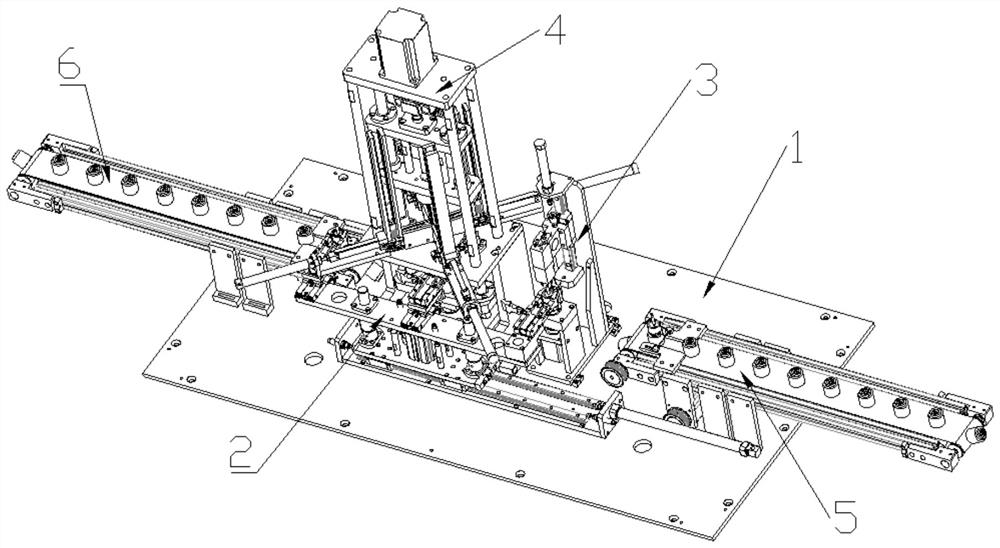

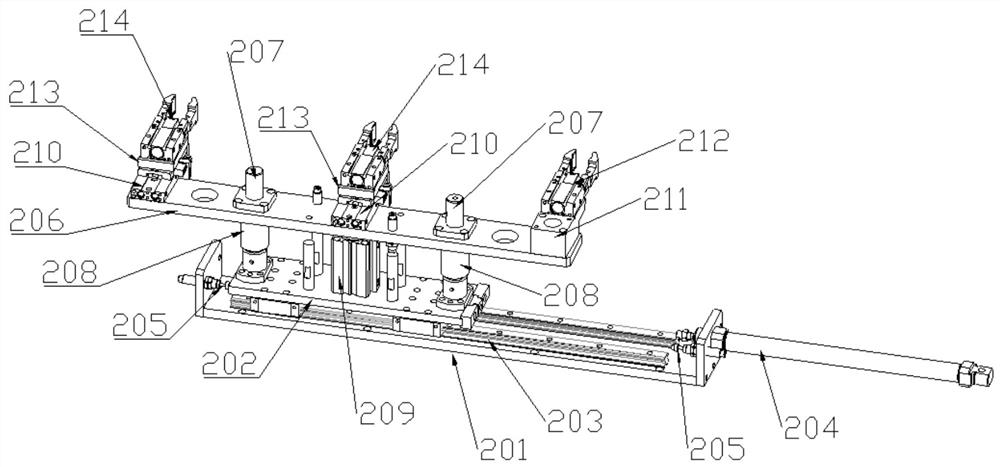

[0042] Such as Figure 1-9 The illustrated automatic magnetizing device for a brushless rotor includes a frame 1 on which a feeding mechanism, a grabbing mechanism 2, a positioning mechanism 3 and a magnetizing mechanism 4 are arranged, and the feeding mechanism includes a feeding mechanism Mechanism 5 and discharging mechanism 6, the grasping mechanism 2 and the magnetizing mechanism 4 are all arranged between the feeding mechanism 5 and the discharging mechanism 6, and the positioning mechanism 3 is arranged on the inlet Between the feeding mechanism 5 and the magnetizing mechanism 4.

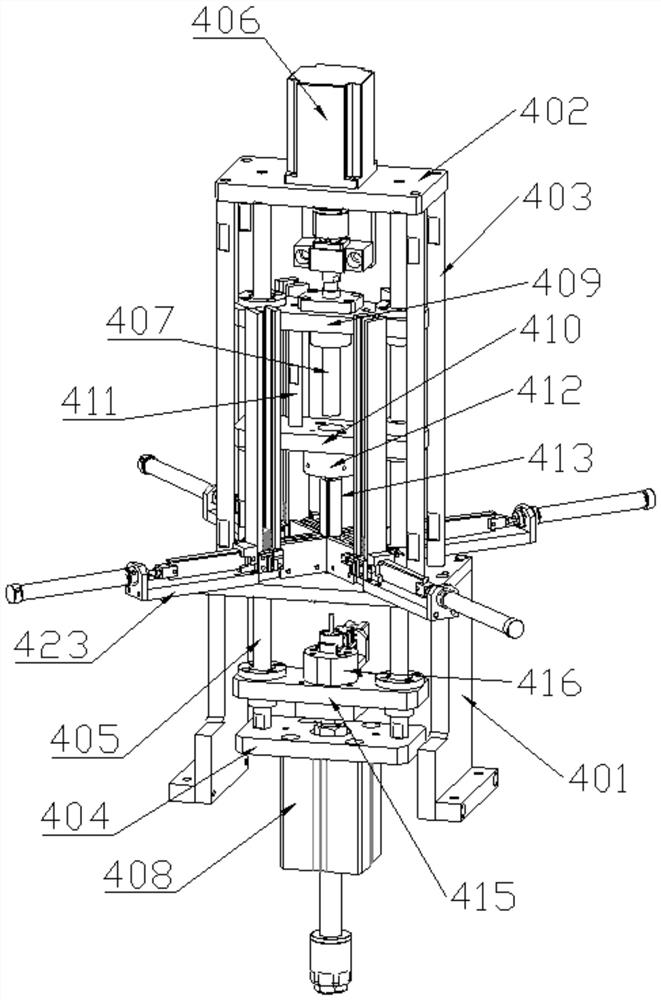

[0043] Specifically, the magnetization mechanism 4 includes a magnetization fixing seat 401, the magnetization fixing seat 401 is arranged on the frame 1, and a magnetization motor fixing seat 402 is arranged above the magnetization fixing seat 401, so that The magneto fixing seat 402 is connected with the magnetizing motor fixing seat 402 through the first magnetizing connecting rod 403, the f

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap