Track plate stripper machine

A demoulding machine and track plate technology, applied in the direction of manufacturing tools, unloading devices, etc., can solve the problems of complex demoulding process, increased equipment cost and equipment construction cost, and achieve the effect of avoiding bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

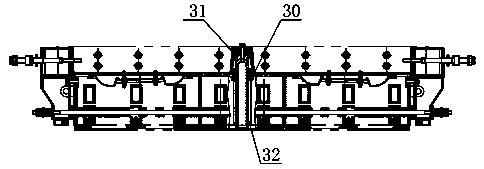

[0022] Such as figure 1 As shown, the prestressed track slab mold in the prior art is schematically shown in the figure, and a prestressed track slab is prefabricated in the track slab mold. It can be seen from the figure that the prestressed track slab has a bottom-up extension and a A grouting hole forming device for forming a grouting hole on the prestressed track plate after pouring. The grouting hole forming device includes a lower cushion block 30 connected to the inner bottom wall of the mold body. The lower cushion block has a through hole that penetrates up and down. Inserted with an upper forming sleeve 31 sealingly connected to its outer ring, the upper forming sleeve is in the shape of a truncated cone with a large bottom and a small top, and a forming device capable of jacking up the grouting hole is slidably connected to the bottom wall of the inner cavity in the track plate mold Thereby, the top sleeve 32 of the molded prestressed track plate is demoulded, and the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap