Feeding device for liquid crystal screen production line

A technology of feeding device and production line, which is applied to conveyor objects, transportation and packaging, trolleys, etc., can solve the problems of poor stability, easy falling off of accessories, easy mutual influence of accessories, etc., and achieves the effect of fixing stability and enhancing suction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

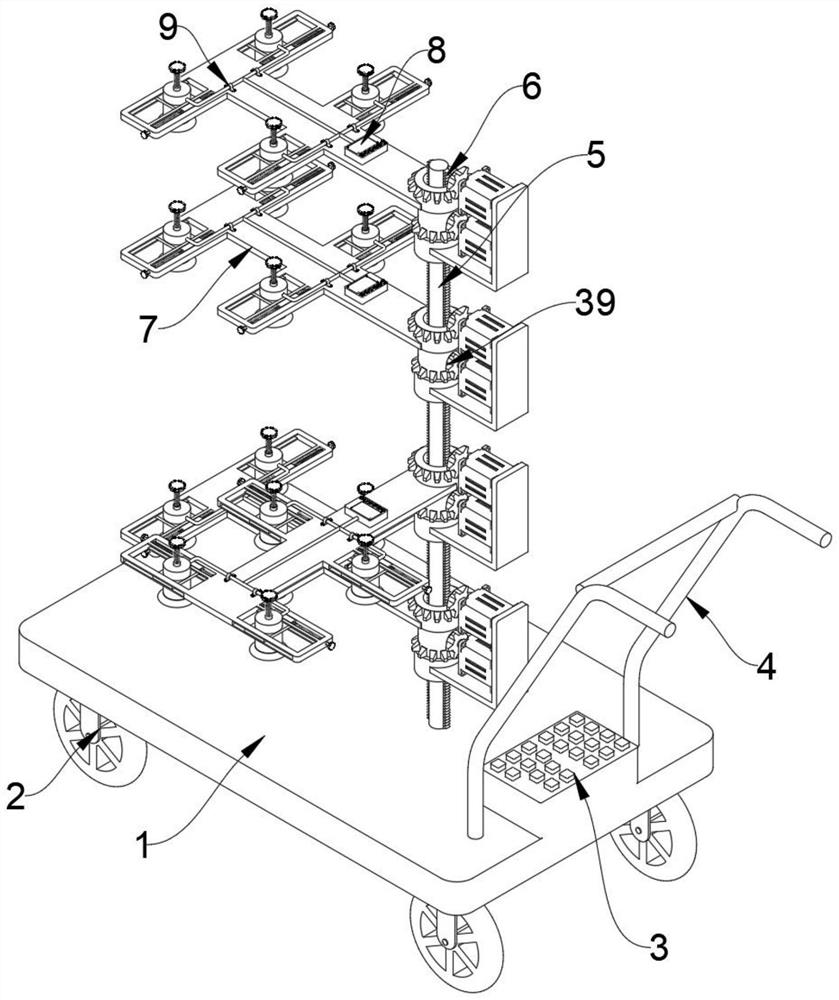

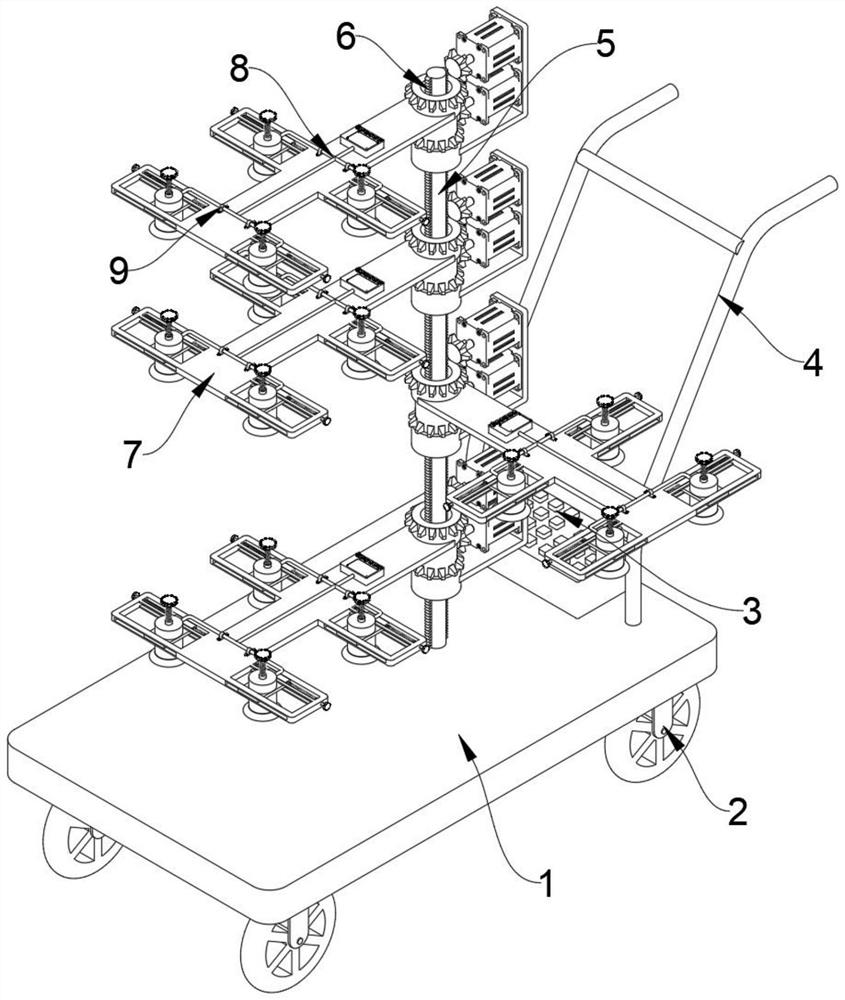

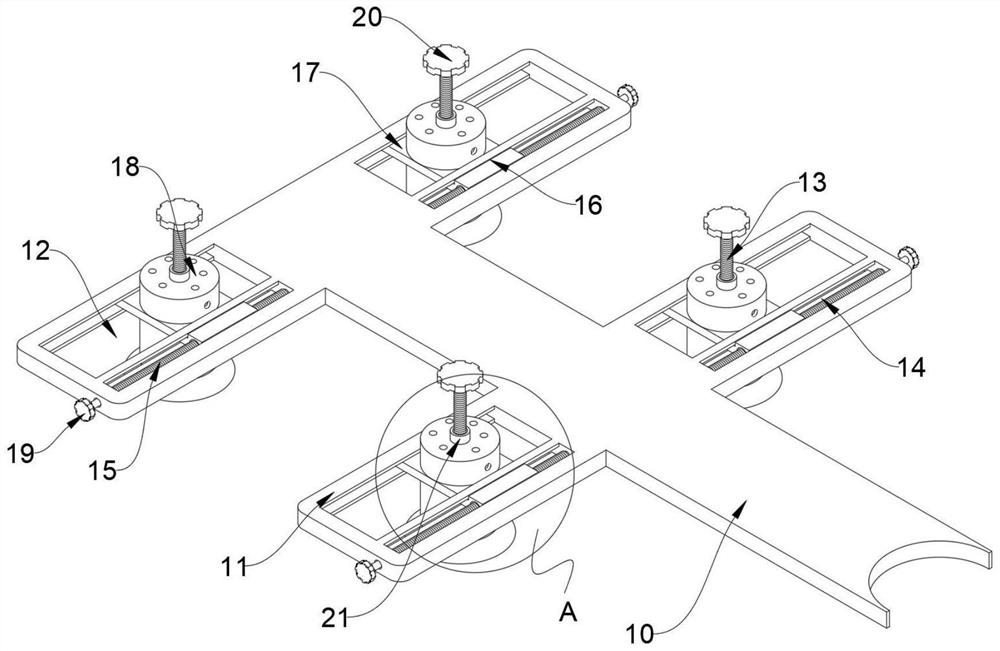

[0029] refer to Figure 1-6 , a feeding device for a liquid crystal screen production line, comprising a fixed base plate 1, four universal wheels 2 are connected by screws at the lower end of the fixed base plate 1, a storage battery 3 is connected by screws on the upper end of the fixed base plate 1, and the upper end of the fixed base plate 1 is welded and connected with The load-bearing rod 5, the two ends of the load-bearing rod 5 are welded and connected with threaded strips 6, and also includes:

[0030] A plurality of transmission mechanisms 39 are installed on the outside of the load-bearing

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap