Production line operation management and control method

A technology of operation management and production line, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems of inability to accurately count the amount and cost of soldering tin, cost changes, and time-to-time changes, and achieve real-time monitoring of operating efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: A production line operation management and control method, which can be applied to various production lines to help managers control production lines, including:

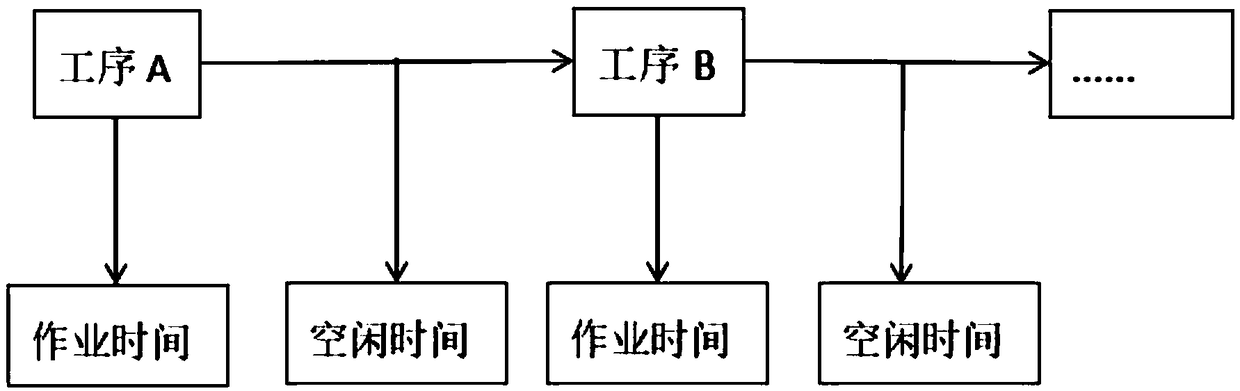

[0025] The induction timing device automatically recognizes the state of the machine or worker in each process, and divides the state into working state and idle state. When the process is manually operated, the induction timing device accepts and delivers products through the preset The template action judges the action of the worker accepting the product, handing out the product, the start of the operation, and the end of the operation; when the process is automated by the machine, the induction timing device judges the status of the corresponding process through the inflow and outflow of the product. see figure 1 , to collect the corresponding working time and idle time. Take the adjacent A process and B process as an example. The working time of A process is the time period from when the produc

Embodiment 2

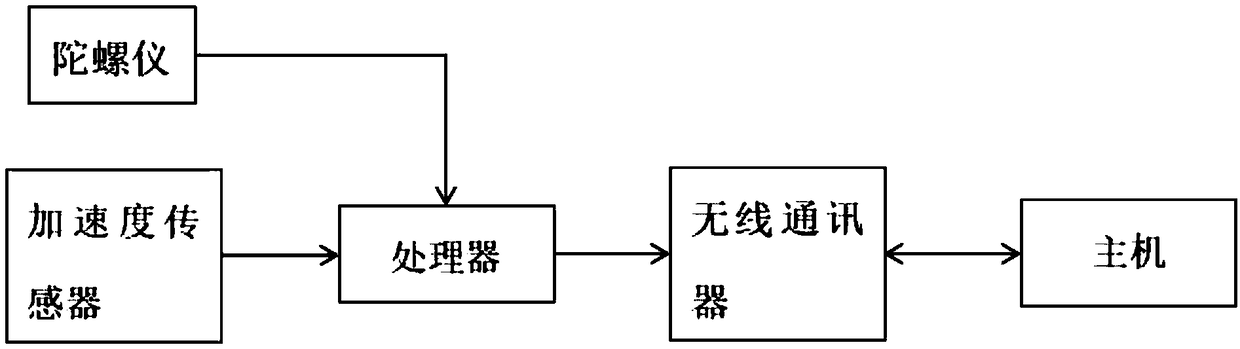

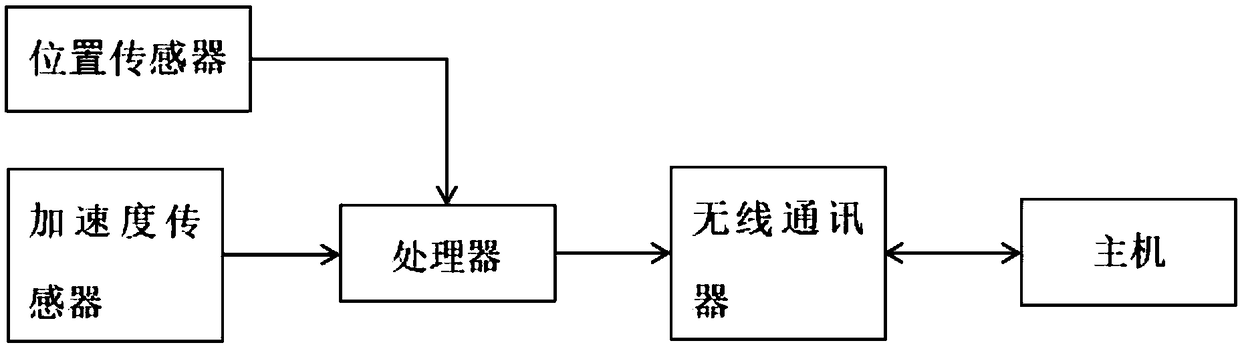

[0028] Embodiment 2: On the basis of Embodiment 1, taking the welding production line as an example, there are manual posts and machine posts. Manual posts are more complicated, including pure manual posts, welding posts, glue dispensing posts, testing posts, etc. Machine posts are relatively simple, and the general process is product inflow, processing, and product outflow, but there are also automatic welding machines, automatic glue dispensing machines, etc. , but no matter whether it is a manual position or a machine position, there are products flowing in and out. For artificial positions, workers have an action of receiving and delivering products and corresponding gestures. Different artificial positions have different operating gestures. Machine posts, with channels for product inflow and outflow.

[0029] Based on the actual situation of the above-mentioned welding production line, the production line operation management and control method proposed by the present inven

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap