Watch movement gear automatic assembly production line

An automated production line and movement technology, applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to meet mass production requirements, high production costs, and low automation, and achieve reliable performance and meet the needs of batch production. The effect of chemical production and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments of the description:

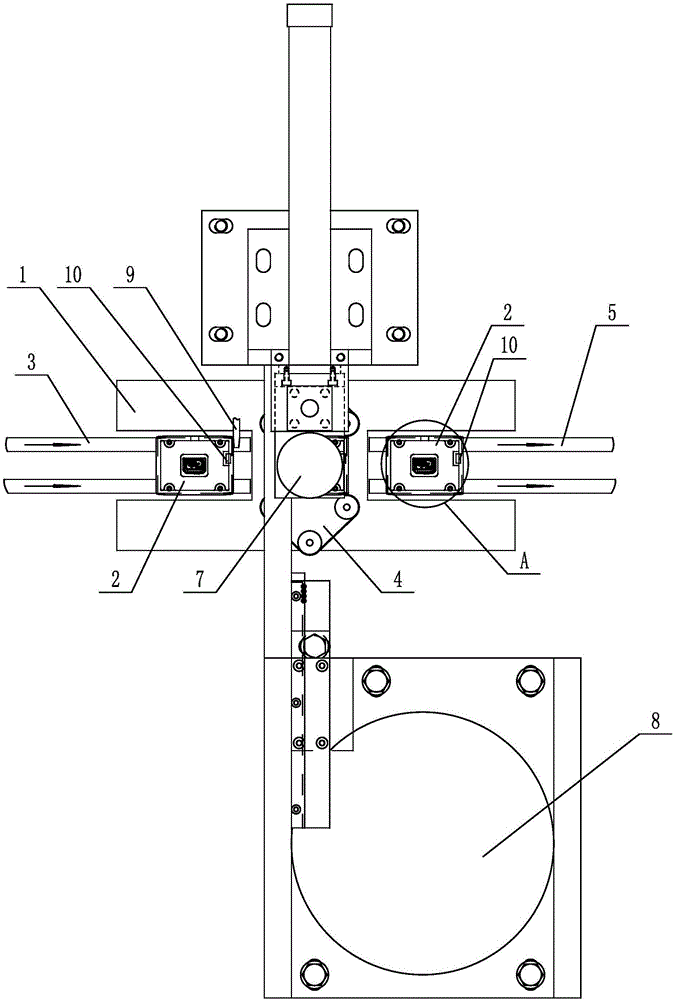

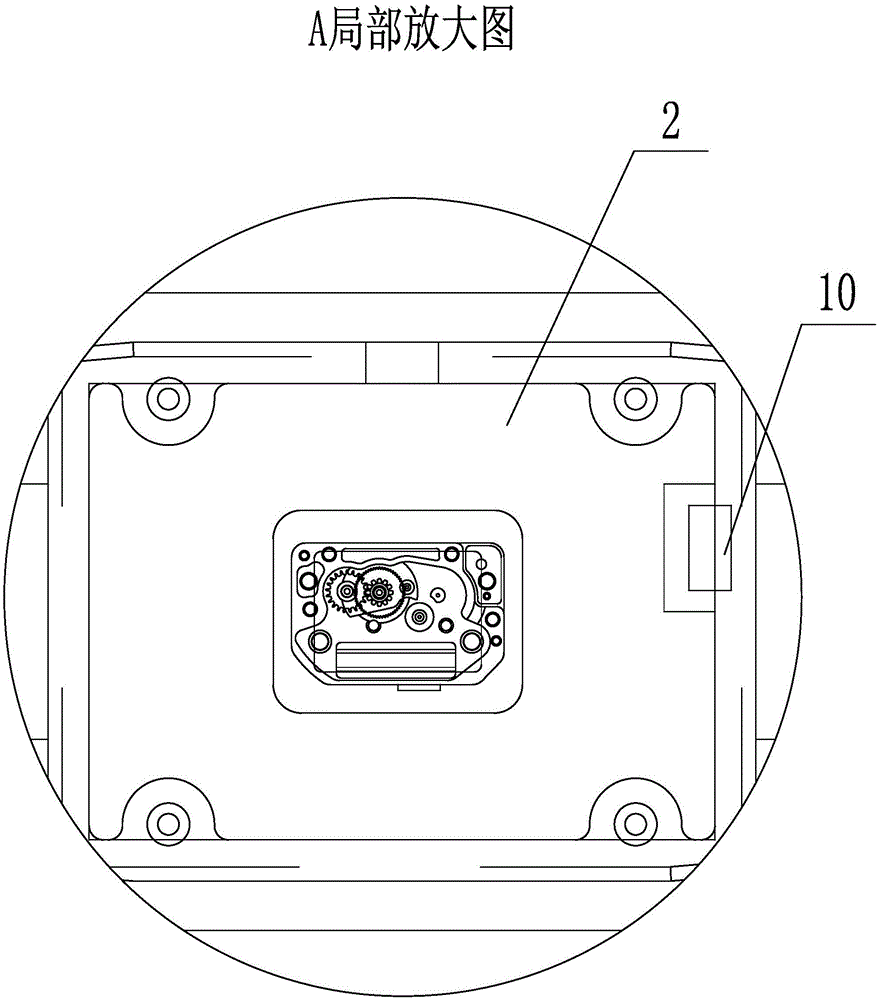

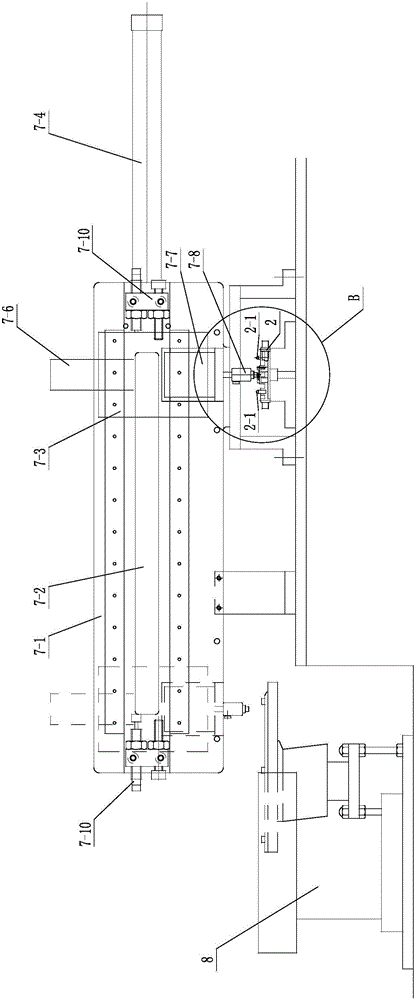

[0033] Such as figure 1 - Figure 6 As shown, it is an automatic production line for watch movement gear assembly provided by the present invention, which is characterized in that it includes a frame 1, an assembly waiting station and an assembly station arranged on the frame 1, and is used for positioning and clamping the watch machine Core movement accompanying tooling 2, conveying device for transporting movement accompanying tooling 2 to the assembly waiting station 3, used for transporting movement movement accompanying tooling 2 from the assembly waiting station to the assembly station and performing pre-positioning Conveying device 2 4. Conveyor device 2 for conveying the movement accompanying tooling 2 completed with gear assembly on the assembly station to the next station The positioning mechanism 6

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap