Automatic control system for variable seeding and fertilization and multifunctional planter

A control system and automatic variable technology, applied in the field of control systems, automatic variable seeding and fertilization control systems, and multi-functional seeders, can solve problems such as easy slippage, ground wheel slippage, and large ground wheel resistance, and achieve convenient, simple and good adjustment. The effect of seeding and the overall structure is reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

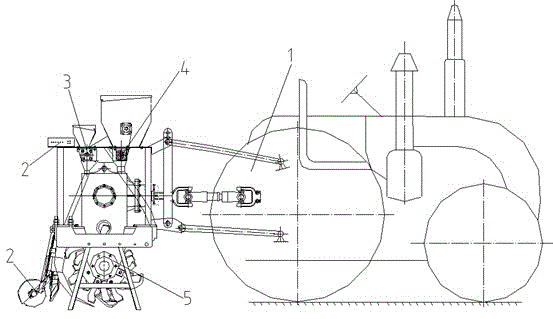

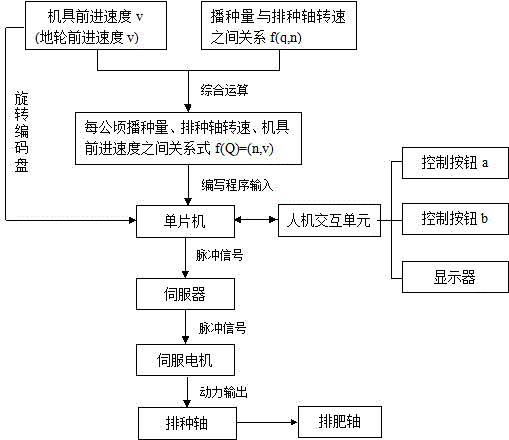

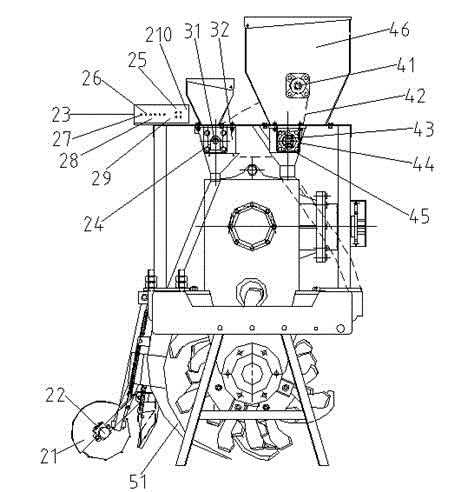

[0025] Such as Figure 1 to Figure 4 As shown, the planter installed in the automatic variable seeding and fertilizing control system of the multifunctional planter of the present invention mainly includes a power system 1, a control system 2, a seeding system 3, a fertilizing system 4, and a rotary tillage ditching system 5. The control system 2 is the automatic variable seeding and fertilization control system of the multifunctional planter of the present invention, which mainly includes the ground wheel 21, the rotary encoder disk 22, the collector box 23, the servo motor 24, the server 25, the single-chip computer 26, the voltage converter 27, the human The machine interaction unit 28, the DC power supply 29 and the power switch 210, wherein the server 25, the single-chip computer 26, the voltage converter 27, the human-machine interaction unit 28,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap