Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Thermal transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

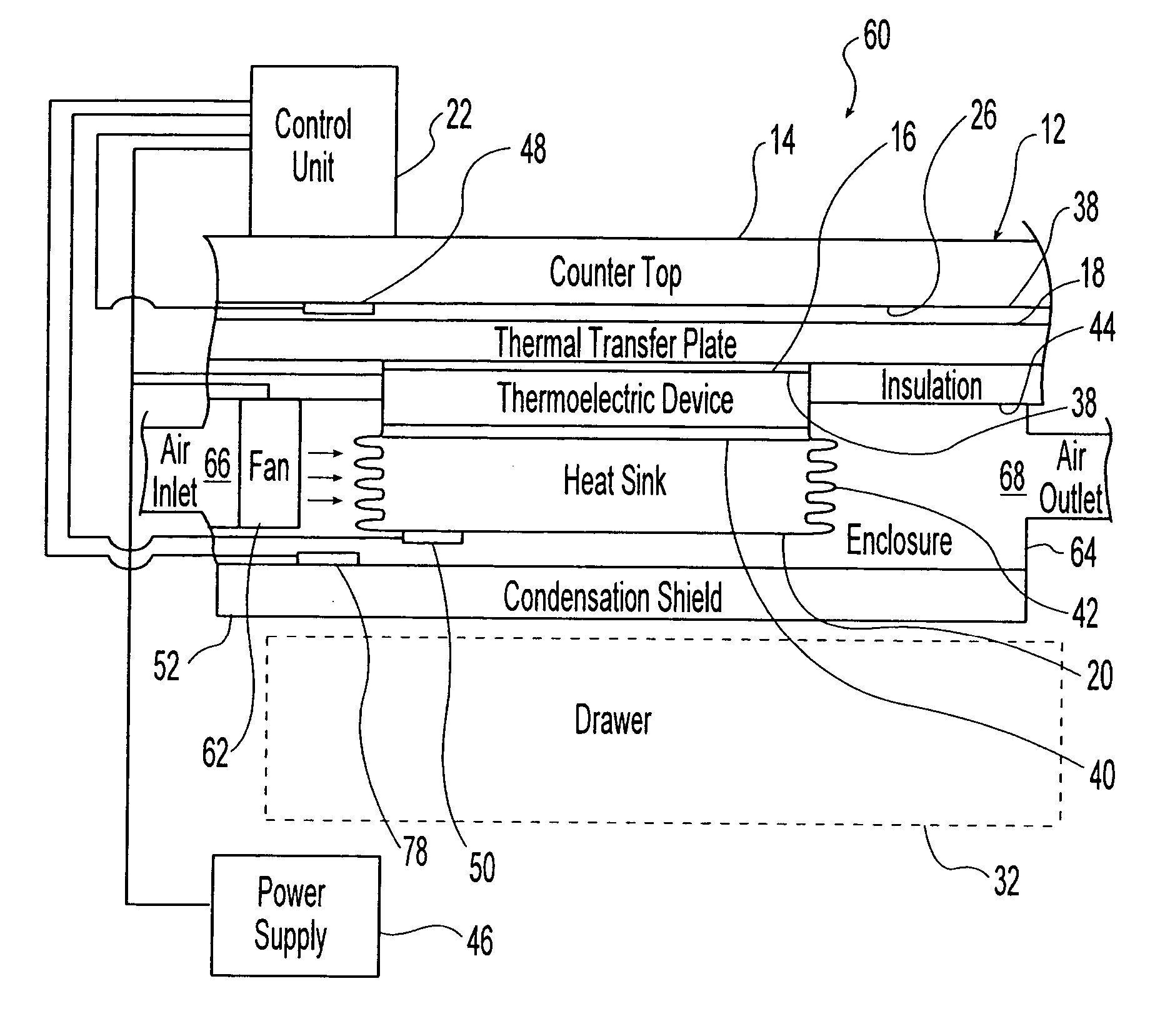

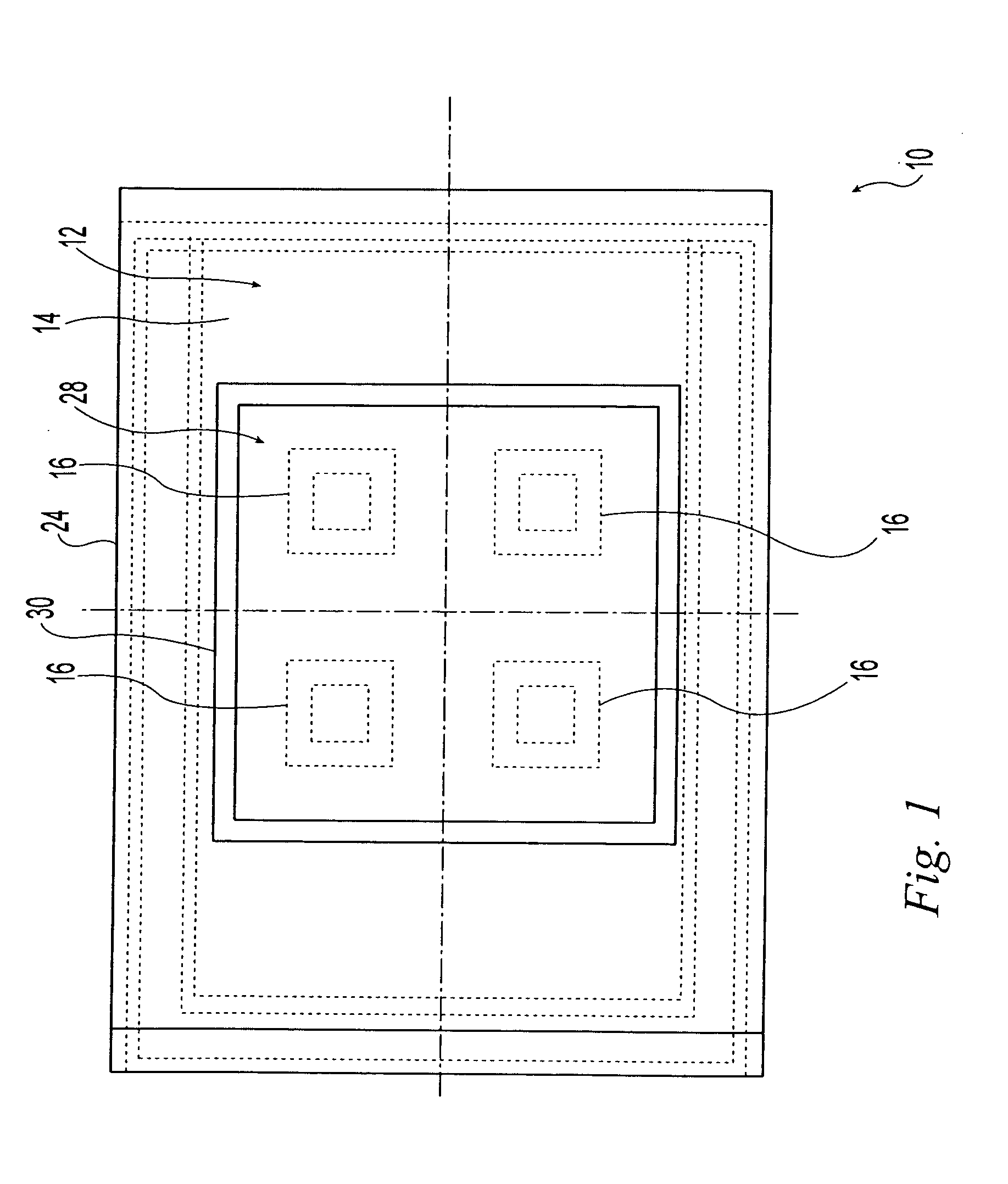

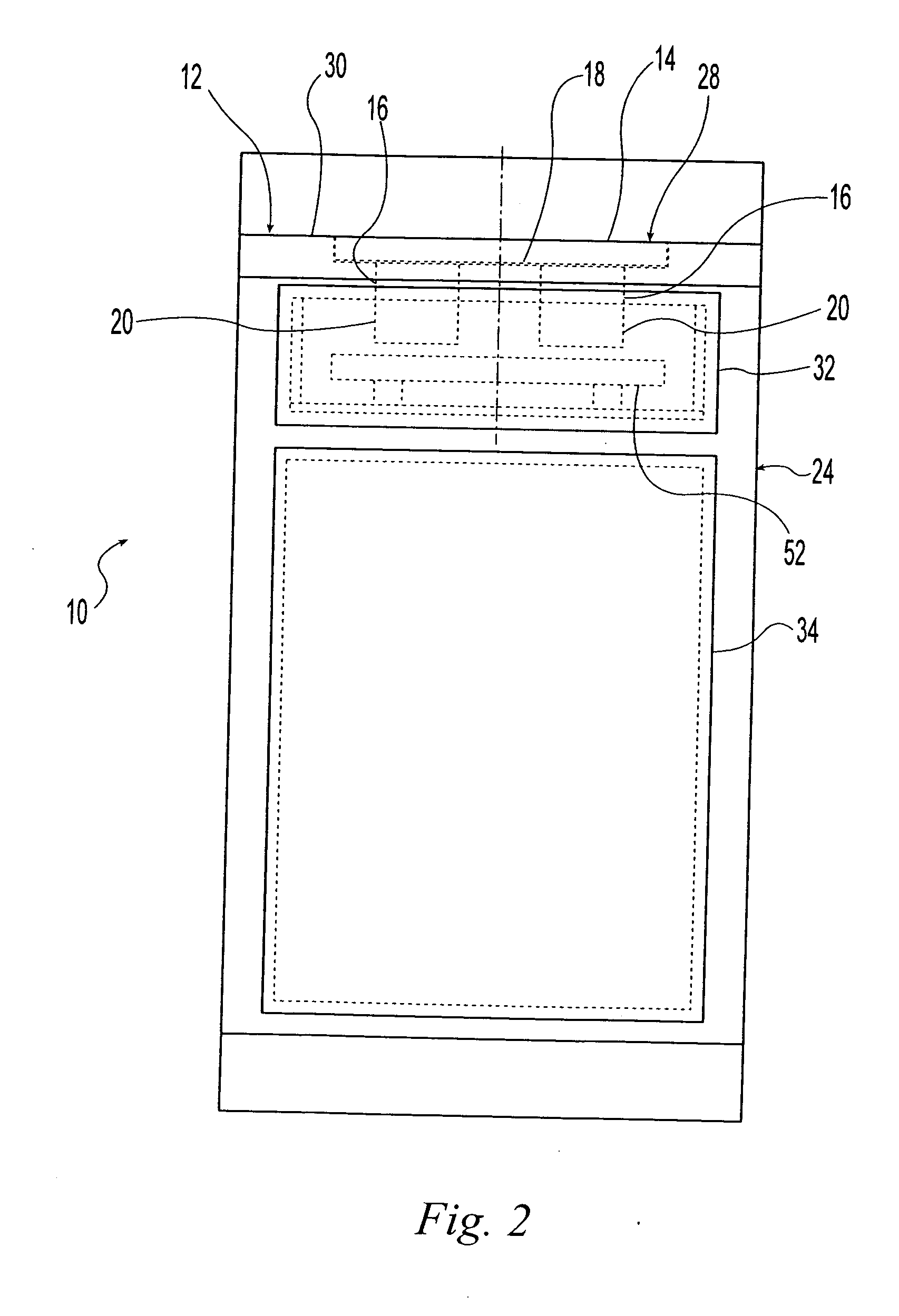

Countertop thermoelectric assembly

Owner:RUCKSTUHL KEITH

Variable air volume system including BTU control function

InactiveUS6879881B1Improving environmental comfortIncrease volumeMechanical apparatusLighting and heating apparatusVariable air volumeAir volume

A method, as well as a controller, for controlling room temperature with a variable air volume system having a plurality of zones wherein the thermal transfer rate with respect to each of such zones is maintained at a substantially constant value notwithstanding changes in the temperature of the supply air thereby providing improved efficiency and environmental comfort.

Owner:SIEMENS IND INC

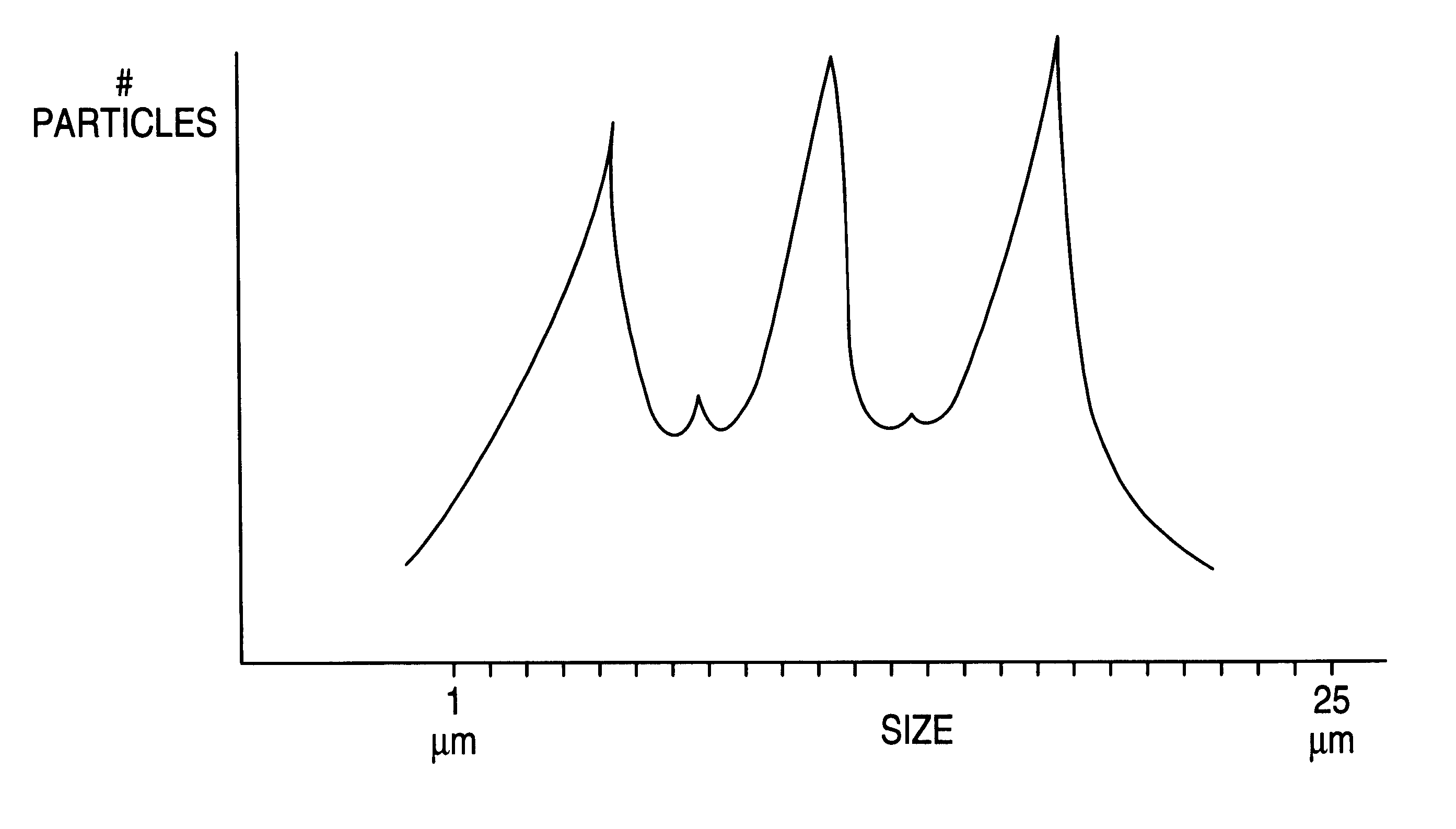

Thermal transfer media with a mixture of non-melting solid particles of distinct sizes

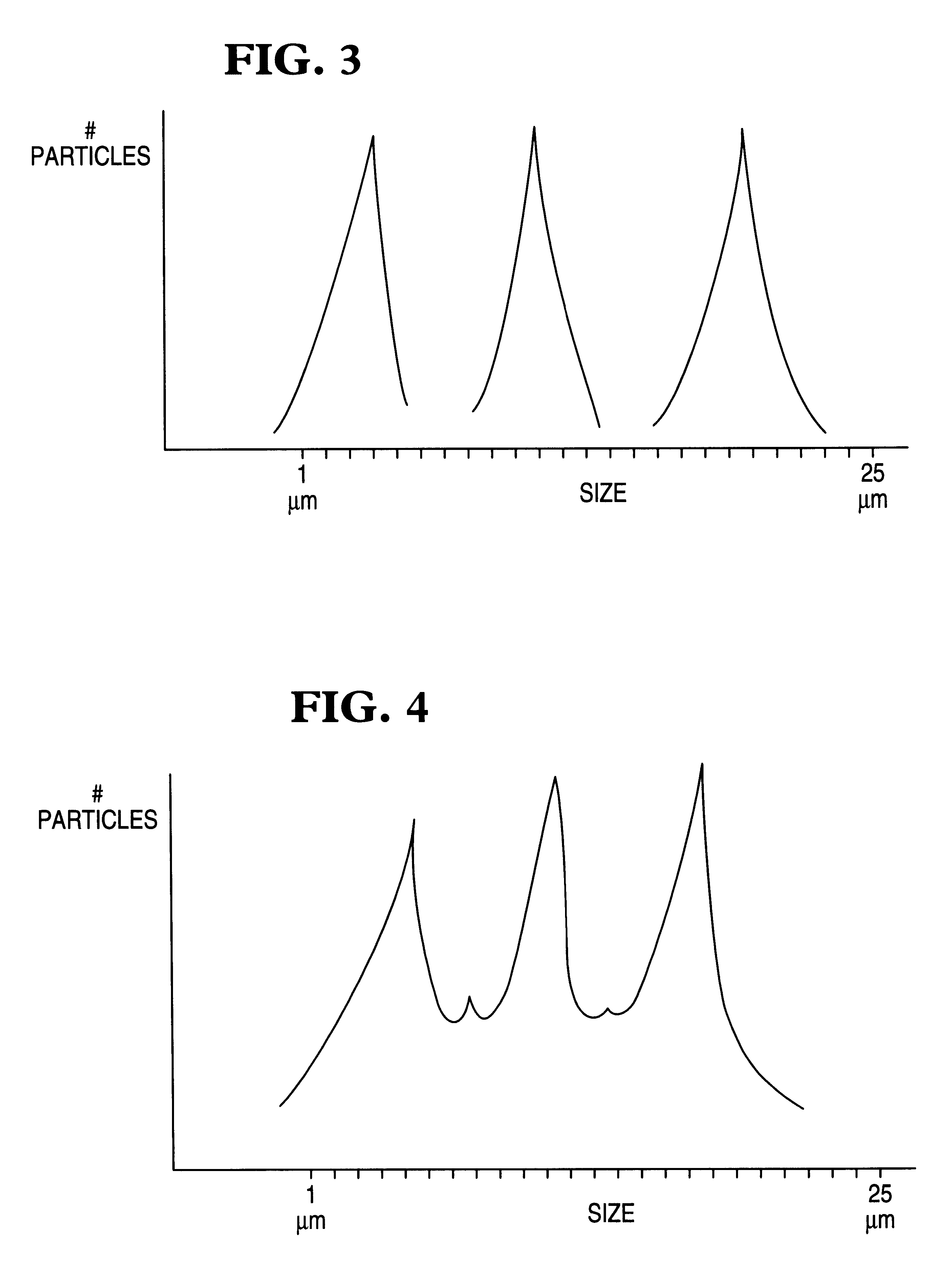

InactiveUS6171690B1Maintaining and reducing melt viscosityHigh densityLayered productsDomestic articlesHigh densitySolid particle

Owner:ICONEX LLC

Method of separating an exposed thermal transfer assemblage

InactiveUS20090105071A1Diffusion transfer processesX-ray/infra-red processesPredictabilityEngineering

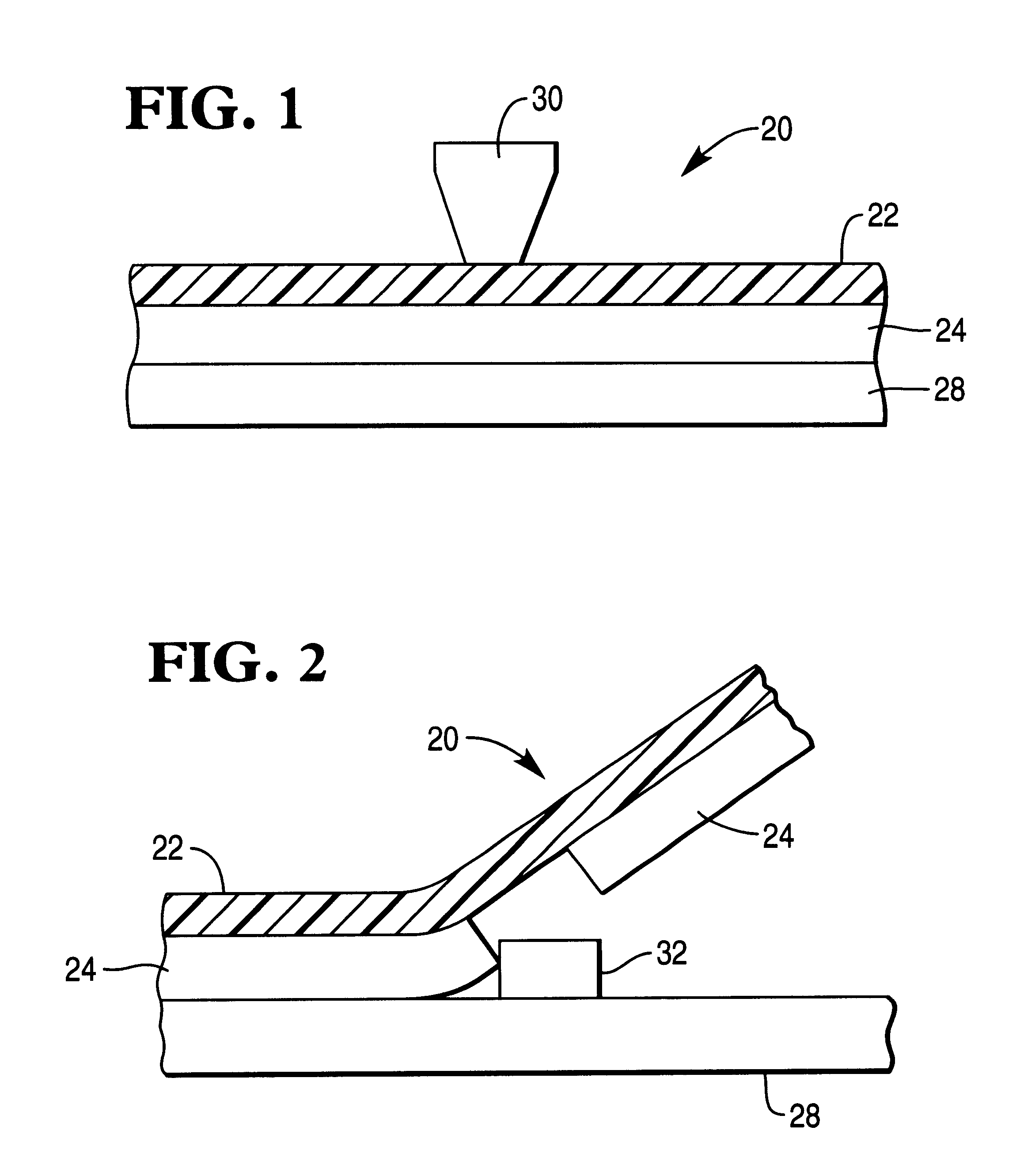

In a method of using a donor element in a radiation-induced thermal transfer process, an assemblage is provided that includes a donor element and a receiver element, wherein the donor element has a support layer and a transfer layer having one side adjacent the support layer and the other side adjacent the receiver element. After image-wise exposing the assemblage to radiation whereby a portion of the transfer layer is transferred to the receiver element, relative movement between the support layer and the receiver element is provided before separating the donor element from the receiver element. Advantages include improved edge straightness, image width predictability, improved thermal mass transfer, and improved color filters.

Owner:EI DU PONT DE NEMOURS & CO

Heat transfer printing printer

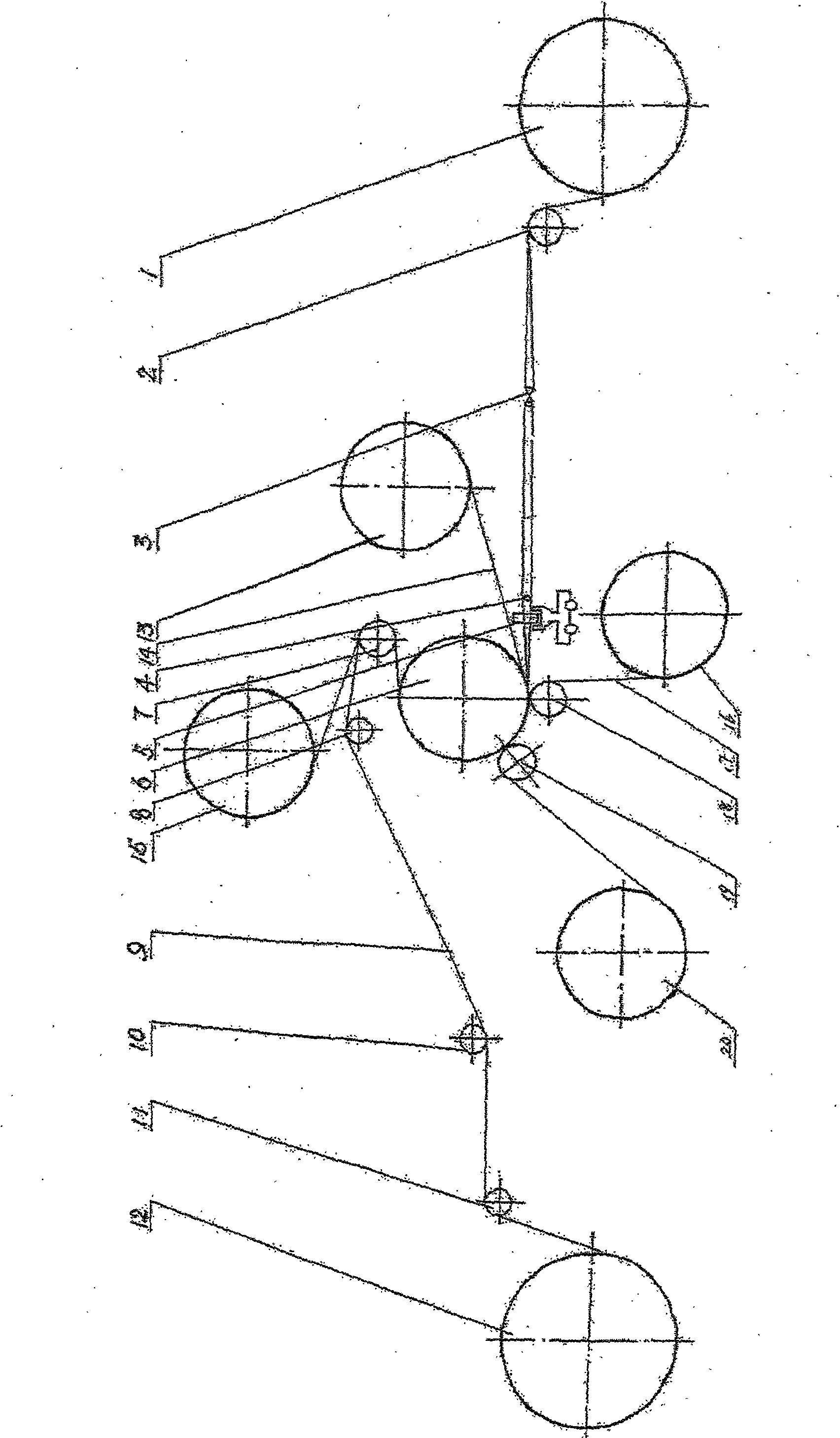

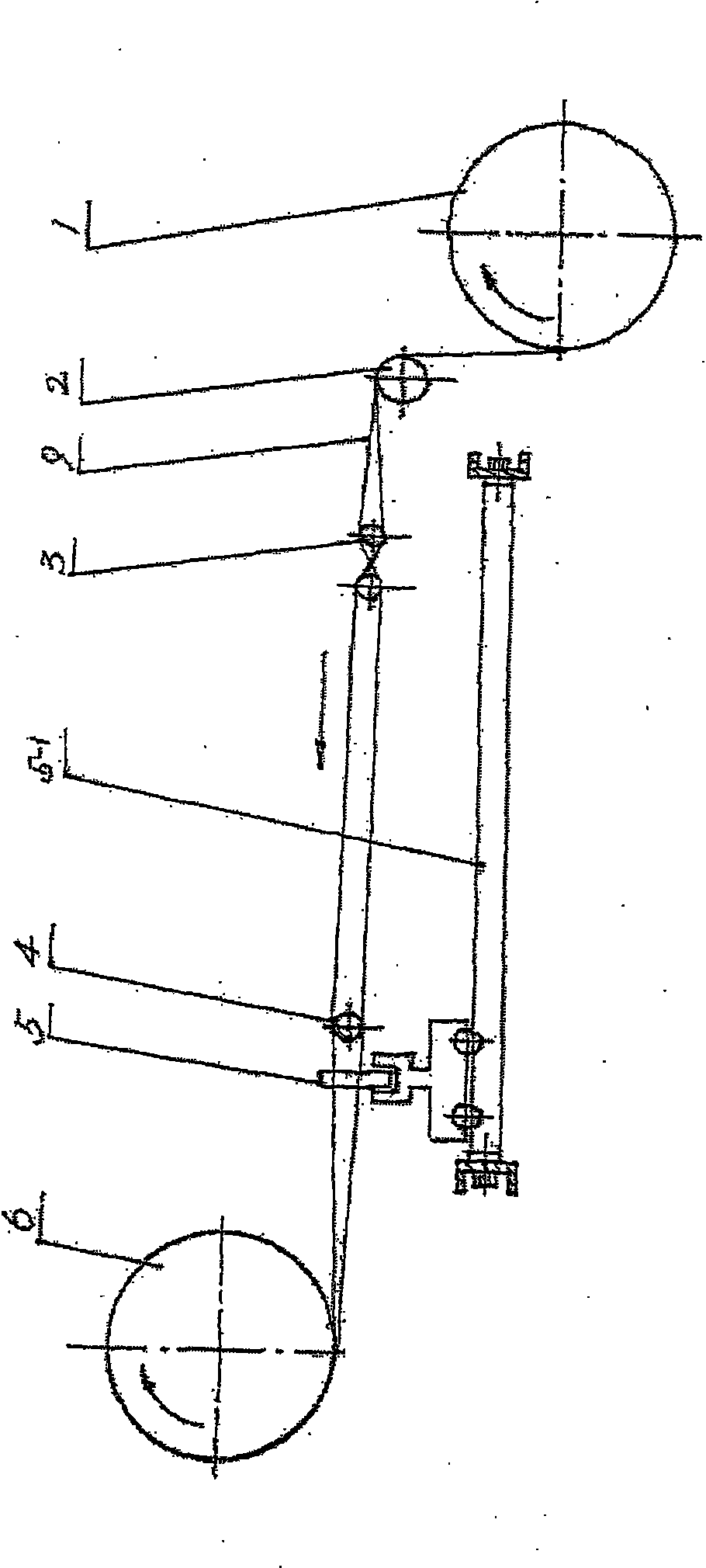

ActiveCN106926588AAvoid wastingReduce printing costsOther printing apparatusSeparated statePaper tape

A heat transfer printing printer comprises a machine base, a printing rubber roller, a printing head bracket, a printing head, a thermal transfer ribbon mechanism, a paper supplying trough, a paper dividing mechanism and a paper feeding mechanism. A lifting mechanism is additionally arranged, first fastening pieces are directly mounted on the power output end of the lifting mechanism, and the lifting mechanism drives the first fastening pieces to lift and drop, so that the printing head and the printing rubber roller are in a closed state or a separation state; meanwhile, a take-up gear and a drive gear are in a meshing state or a separation state; and in the separation state, winding of a thermal transfer ribbon is suspended, so that thermal transfer ribbon waste caused by thermal transfer ribbon empty winding at the time of printing blank data is avoided, the thermal transfer ribbon is saved by a large margin, and printing cost is reduced. Limit partition boards and limit adjustment mechanisms are arranged on the two sides of a paper feeding belt and paper feeding pinch rollers, when the printing head is locally damaged and needs to change the printing position, the positions of the limit partition boards are changed by adjusting the limit adjustment mechanisms of the corresponding limit partition boards, so that the printing head can still print normally under the condition of local damage, and the printing cost is reduced.

Owner:SHANTOU HIGH TECH ZONE JUSHENG TECH CO LTD

Thermal transfer warp printing machine

InactiveCN101885263AReduce overlapShort production processTransfer printingDyeing processPulp and paper industryThermal transfer

Owner:WUJIANG NEW DEV TEXTILE

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap