Drill bit for engineering geological drilling

A technology of engineering geology and drill bits, which is applied in the direction of drill bits, drill pipes, drill pipes, etc., can solve the problems of inability to assemble the physical properties of parts, reduce wear resistance, and drill bits cannot be replaced, so as to achieve stable and reliable design and improve wear resistance damage, high practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

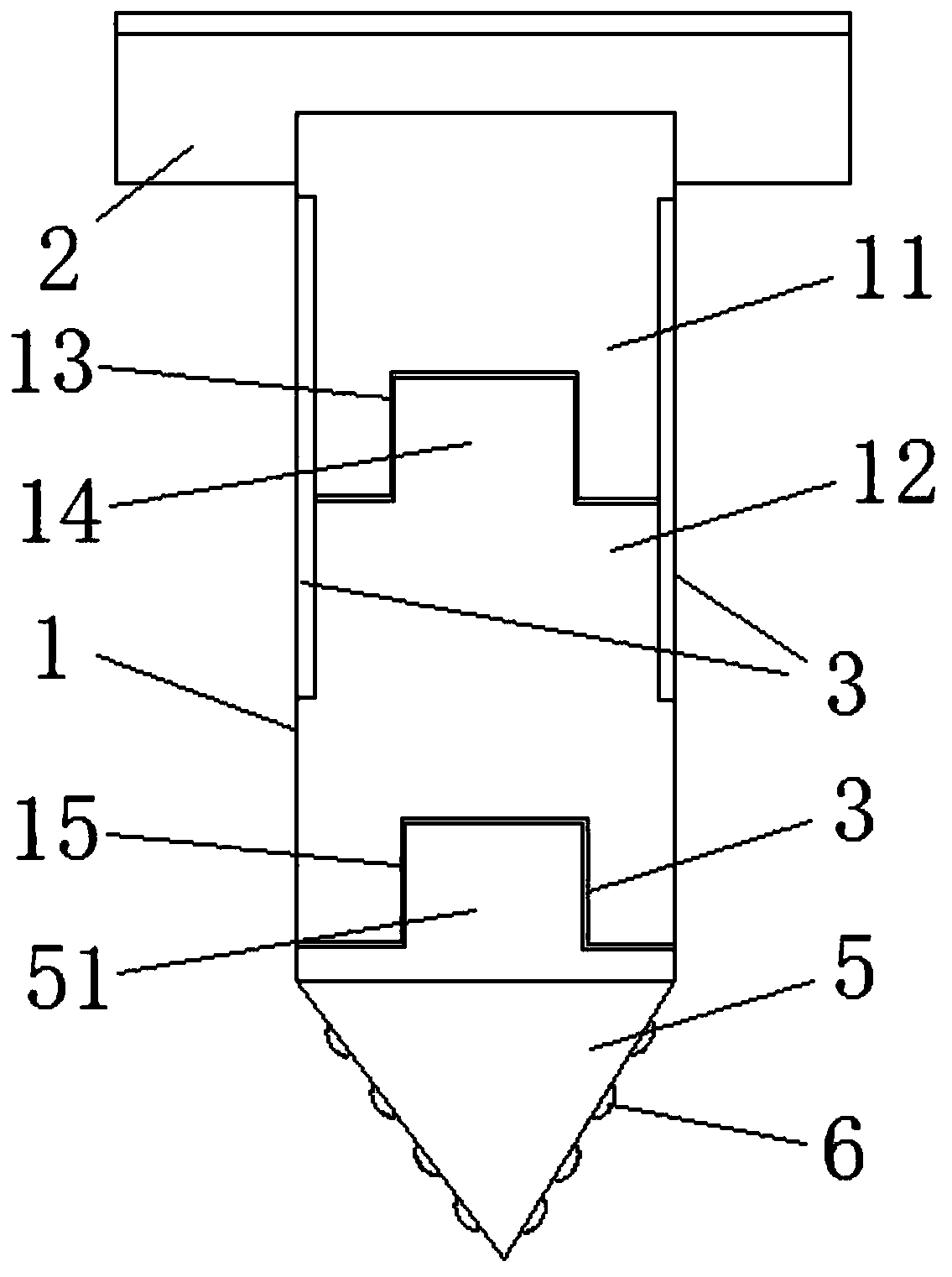

[0017] Refer to attached figure 1 , the present embodiment provides a drill bit for engineering geological drilling, comprising a drill rod 1, a drill shank 2 fixed to opposite ends of the drill rod 1, and a drill bit 5, the drill bit 5 is a conical structure, and the outer surface of the drill bit 5 is distributed and fixed with Reinforcement block 6, the reinforcement block 6 is an arc-shaped convex structure, the reinforcement block 6 is arranged longitudinally on the outer surface of the drill bit 5, and the drill pipe 1 is formed by docking the first drill pipe 11 and the second drill pipe 12, and the second A reinforcement layer 3 is fixed on the outer periphery of the joint between the first drill pipe 11 and the second drill pipe 12, and the reinforcement layer 3 is preferably a high manganese steel reinforcement layer.

[0018] The first drill rod 11 is threadedly connected with the second drill rod 12, and one end of the first drill rod 11 is provided with a first threa

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap