Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Measurement precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Measurement precision. The amount of variation that exists in the values of multiple measurements of the same factor. Greater precision means less variation between measurements. Measurement precision is not to be confused with measurement accuracy, which depends on the level of agreement between the measurement and a known standard.

Sample measurement device, sample measurement system and sample measurement method

ActiveUS20100283488A1Reduce measurement errorImmobilised enzymesBioreactor/fermenter combinationsMeasurement deviceVoltage source

A sample measurement device (110), in which a biosensor (30) having an electrode is mounted, voltage is applied to the electrode, and the concentration of a specific component in a sample deposited on the biosensor (30) is measured, comprises a voltage source (19) configured to apply voltage to the electrode, a time measurement component (22), and a controller (18) configured to control the voltage to be applied and measure the concentration of the specific component. The time measurement component (22) measures a detection time, which is the length of time between the mounting of the biosensor (30) and the deposition of a sample on the biosensor (30). The controller (18) changes a set value for measuring the concentration of a specific component according to the detection time. Consequently, measurement accuracy can be improved regardless of the temperature of the biosensor (30).

Owner:PHC HLDG CORP

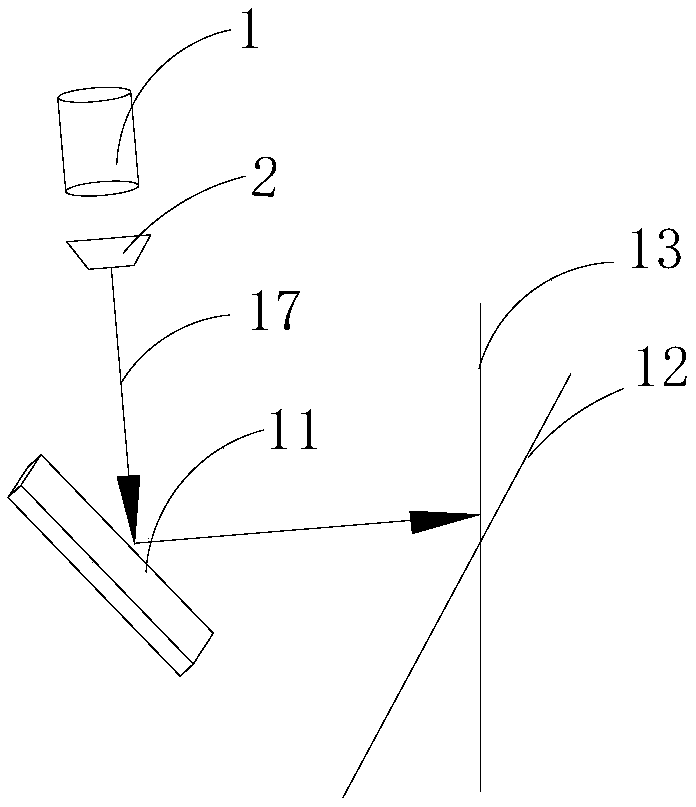

Method and device for measuring tunnel lining cracks

ActiveCN101957178ALow costQuick fixImage analysisUsing optical meansMeasurement deviceImage segmentation

The invention relates to a method for measuring tunnel lining cracks. The method comprises the following steps of: acquiring an image of a crack by a digital camera and measuring the acquisition distance by a laser ranger; selecting an area needing to be measured from the acquired image so as to prevent processing deviation due to excessively big picture and relatively small target crack, and changing the selected area into a gray image; determining a threshold for the selected gray image and performing binarization image division to obtain a target area; extracting a white area only comprising the crack from the target area; extracting the border of the crack to obtain a border graph; calculating the pixel width of the crack by a minimum distance method; and obtaining the actual width of the crack according to a predetermined calibration proportion between the actual pixel size and the photographing distance. The method has the advantages of low cost, high speed, convenient carrying and high measurement precision.

Owner:SHANGHAI TONGYAN CIVIL ENGINEERING TECHNOLOGY CORP LTD

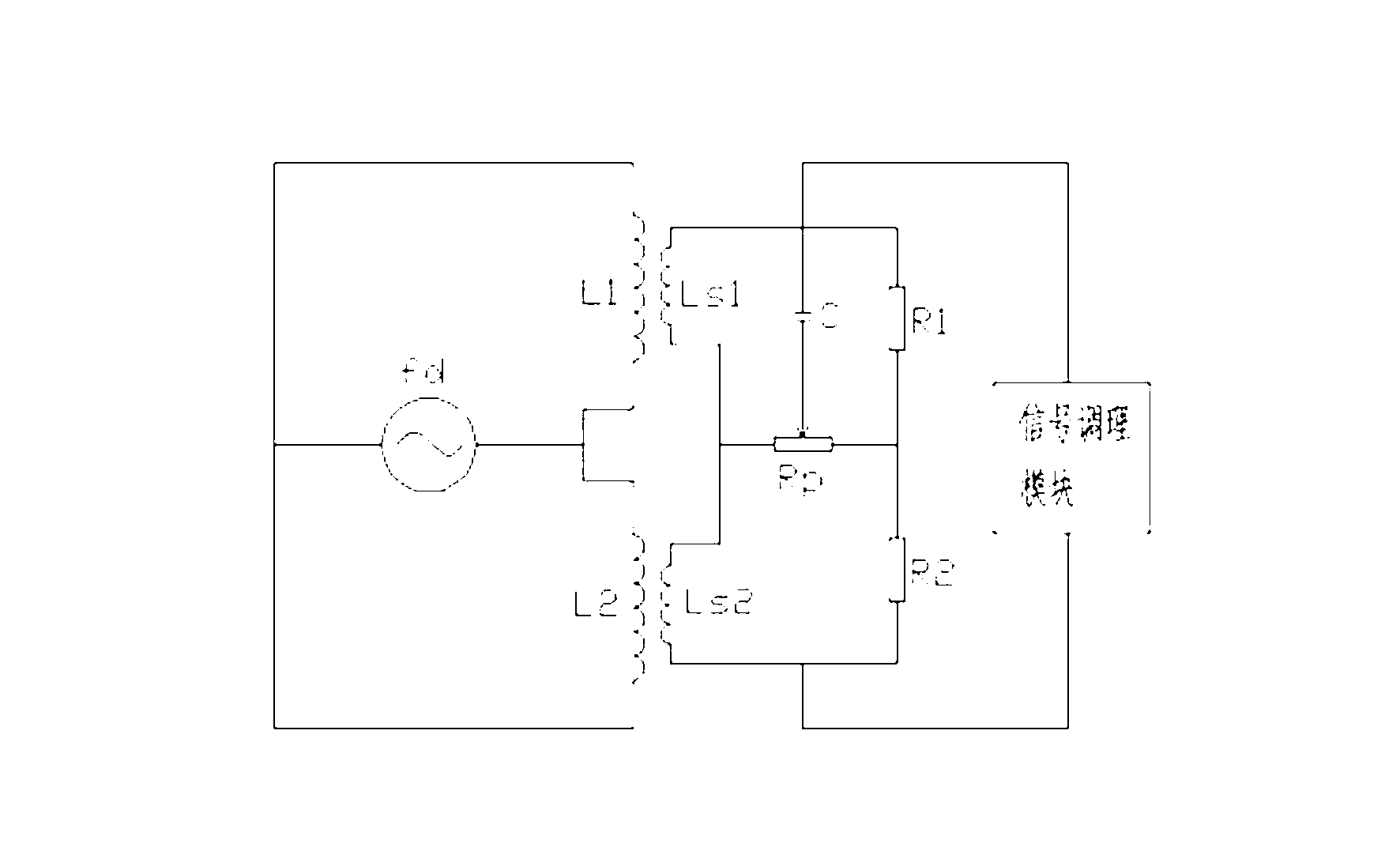

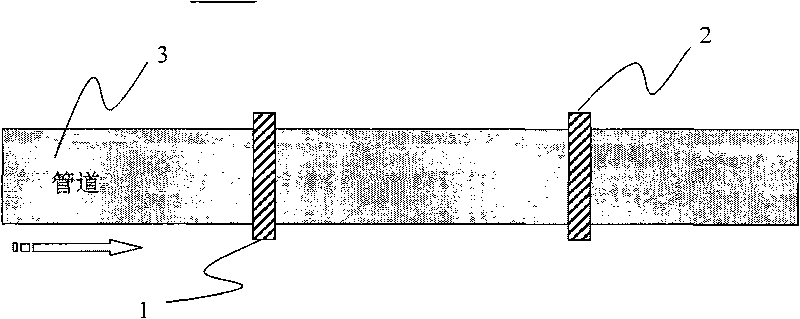

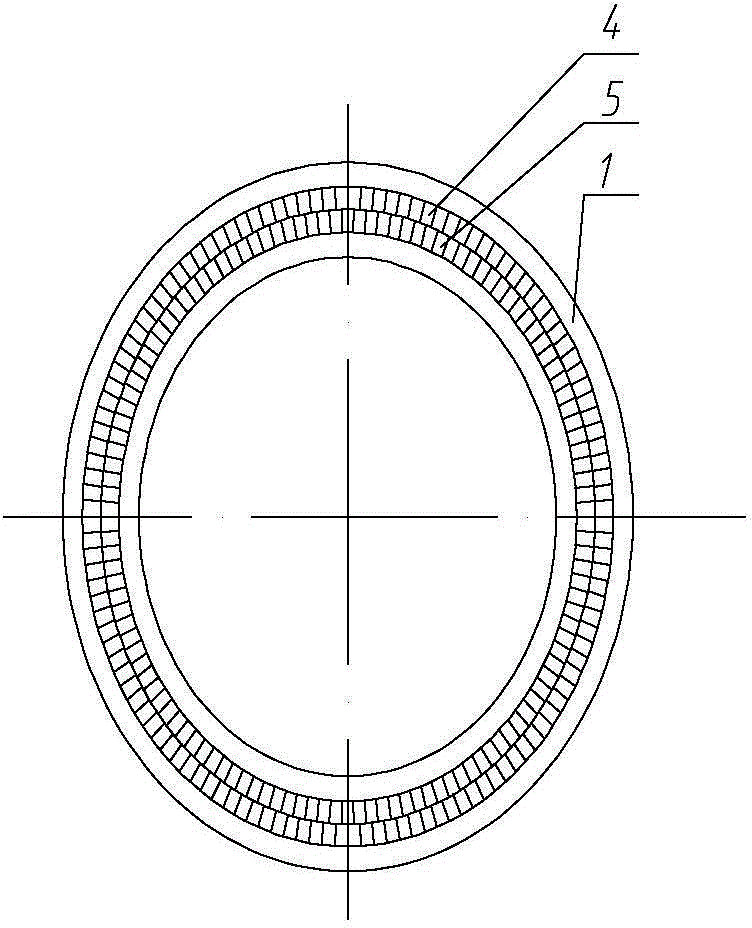

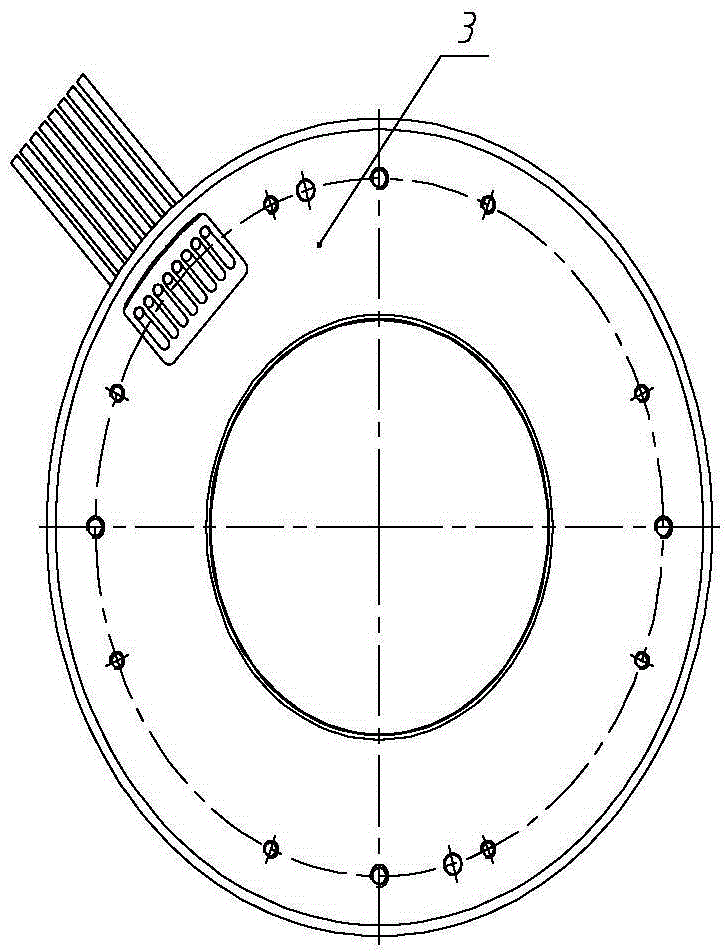

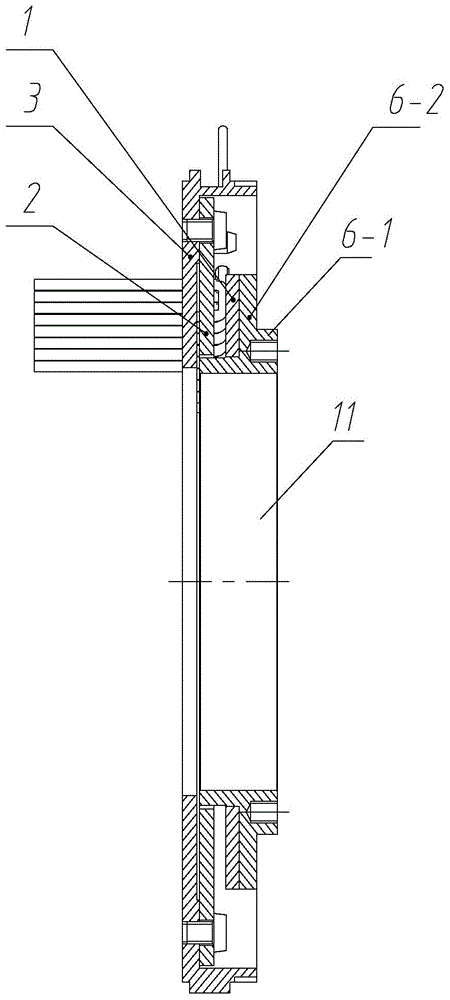

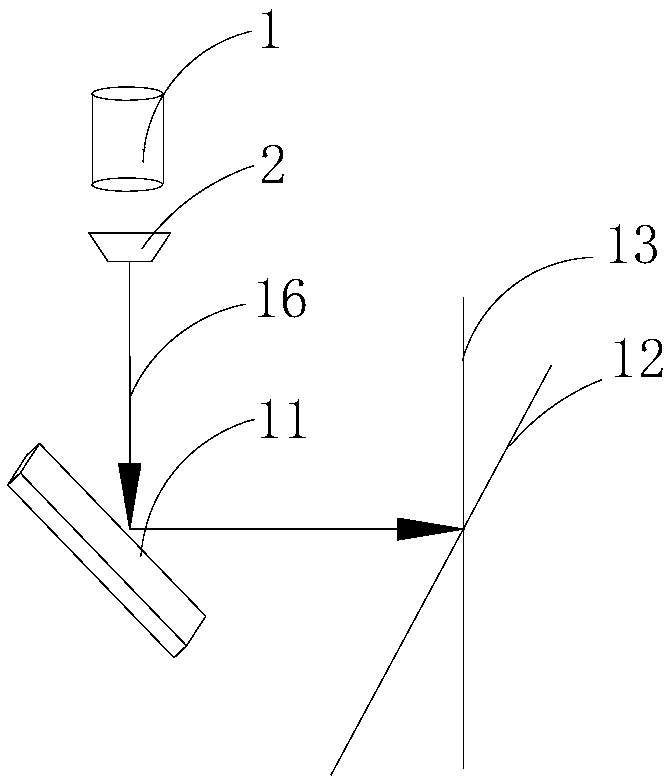

Sensor for monitoring metal abrasive particles in oil liquid on line and application method for sensor

InactiveCN103308431AReasonable structureHigh sensitivityMaterial analysisMechanical equipmentLinearity

Owner:GUILIN UNIV OF ELECTRONIC TECH

Precision improvement calibrating method for current vortex sensor

InactiveCN101793493AHigh precisionAdapt to the actual needs of the projectUsing electrical meansConverting sensor output electrically/magneticallyElectricityMathematical model

The invention discloses a precision improvement calibrating method for a current vortex sensor, which is used for calibrating precision by finding an optimal linear range in which the current vortex sensor can meet requirements so that the current vortex sensor measures at the highest precision in the range meeting the requirements and the established mathematical models are simultaneously minimum. The invention has the advantages of convenient use, high stability and good economical efficiency and furthest utilizes the existing measuring range of the current vortex sensor on the basis of improving the precision of the sensor. A method in the greatest range simplifies the error correction process of the sensor and achieves the purpose of improving the measuring precision by using minimum mathematical models.

Owner:HEFEI UNIV OF TECH

Flow rate measuring system and method for multiphase fluid

InactiveCN101750124AReduce complexityHigh measurement accuracyVolume/mass flow measurementFluid speed measurementMeasurement deviceMathematical model

Owner:北京中油联自动化技术开发有限公司

Fiber temperature sensor and measuring system thereof and signal processing method of system

ActiveCN102410886AEliminate errorsHigh measurement sensitivityThermometers using physical/chemical changesRefractive indexFluorescent light

The invention discloses a fiber temperature sensor and a measuring system thereof and a signal processing method of the system. The fiber temperature sensor is composed of a normal fiber and a photonic crystal fiber. Two ends of the photonic crystal fiber are welded with the normal fiber, so that a fiber temperature sensor is formed. Pores of the photonic crystal fiber are filled with fluorescent substances and refractive index temperature sensitive substances. The normal fiber is a multi-mode fiber or a single-mode fiber. And the fiber temperature sensor measuring system comprises a light source, the fiber temperature sensor, a coupler, a filter, a detector and a signal processing unit. When a signal is processed, an exciting light and a fluorescent light are used as temperature measurement parameters, wherein the exciting light and the fluorescent light are output by the sensor, and an intensity ratio of the exciting light to the fluorescent light is also used as a temperature measurement parameter, so that a multi-parameter measurement temperature is formed; and therefore, sensitivity and measurement precision of the fiber temperature sensor are improved.

Owner:SHENZHEN UNIV

White light microscopic interference morphology reconstruction method based on mixing interference fringe

ActiveCN106643559AHigh measurement accuracyStrong measurement stabilityUsing optical meansMicro nanoPoint light

The present invention provides a white light microscopic interference morphology reconstruction method based on a mixing interference fringe. A Mirau-type white light interferometry optical system is employed, a piezoelectric ceramics mobile station is employed to perform precision control of the vertical scanning movement of an interference objective, and a series of collected white light microscopy interferograms are stored. The collected interference grey-scale map is converted to a light intensity graph, a normalization modulation degree graph corresponding to a single-frame interference image is obtained through the frequency domain filtering and the base frequency signal extraction algorithm, and aiming at each independent vertical scanning position, a mixing interference image is obtained through the multiple of the same pixel point light intensity value and the corresponding modulation degree numerical value. A series of mixing interference images are obtained through vertical scanning, and the height information of each pixel point of a detected object is obtained through searching the mixing interference extreme value and the corresponding scanning displacement thereof to realize the three-dimensional morphology reconstruction of the object. The white light microscopic interference morphology reconstruction method based on the mixing interference fringe is high in measurement precision, high in anti-interference capability and simple in system, and is suitable for three-dimensional morphology detection of the micro-nano structure.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

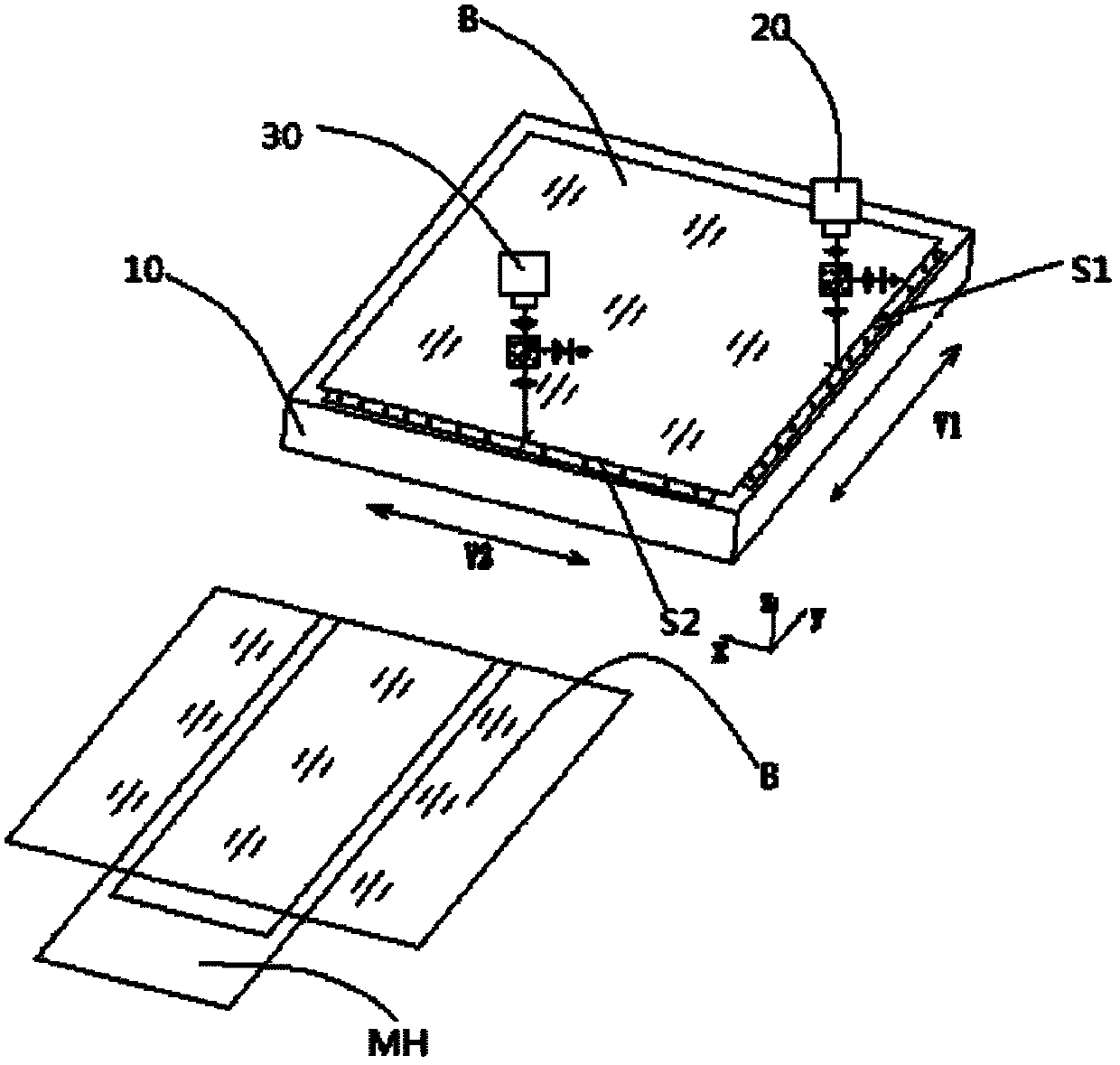

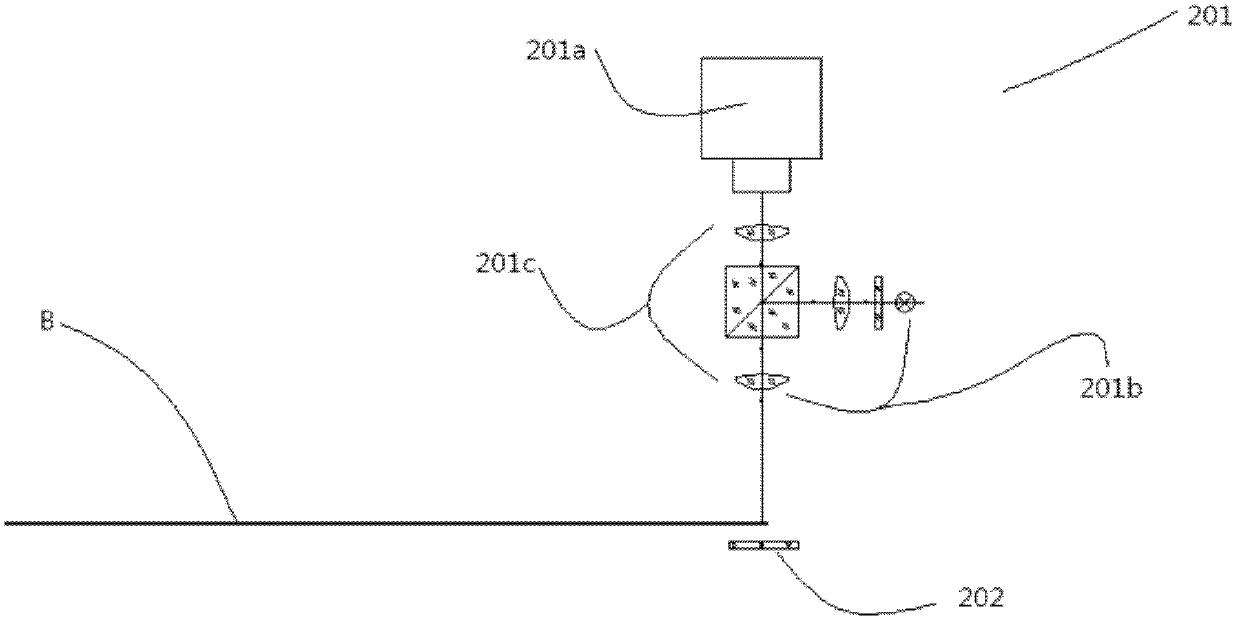

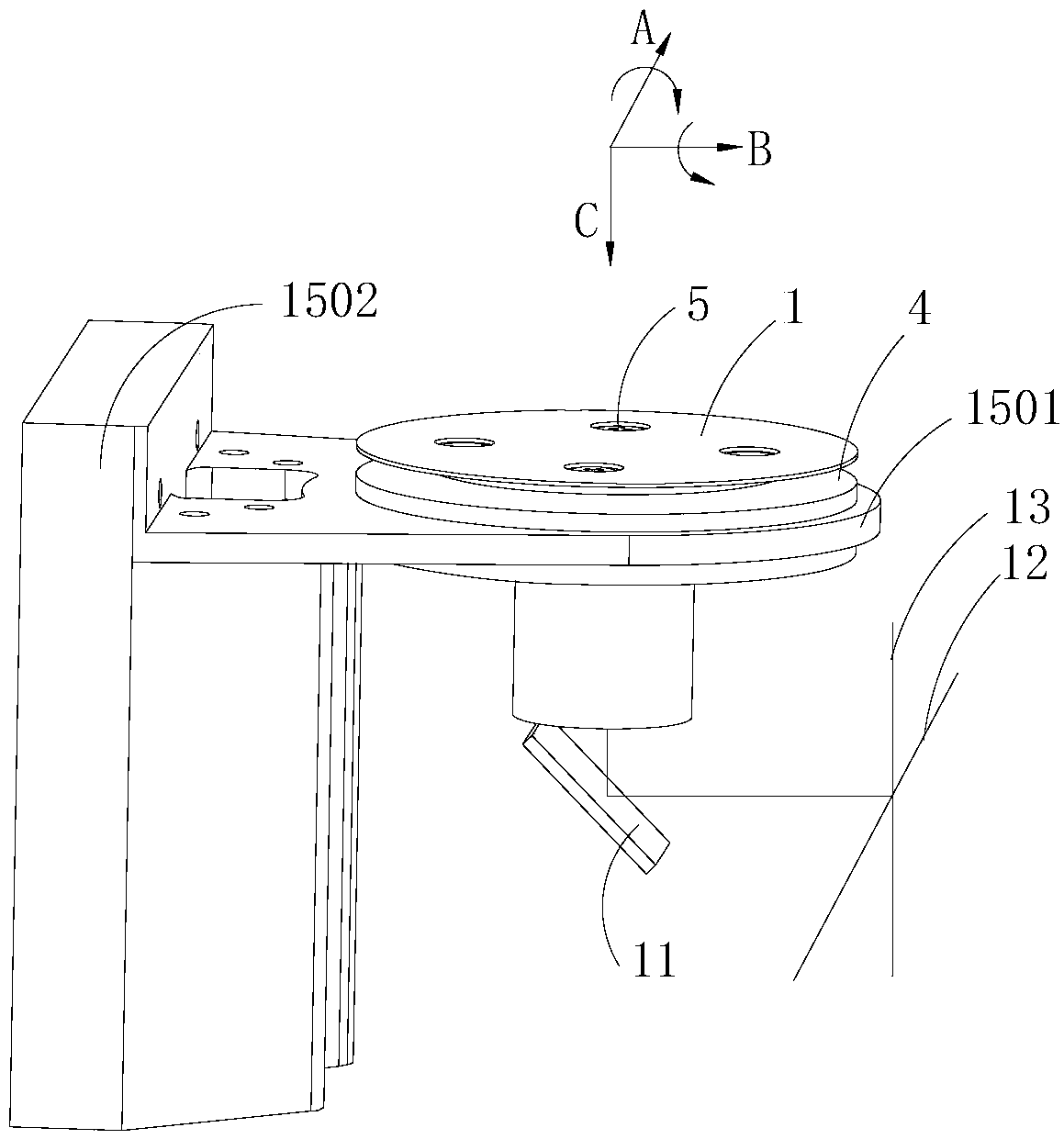

Pre-alignment device and method of square substrates

ActiveCN103293867AWon't breakImprove alignment accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusRobot handEngineering

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

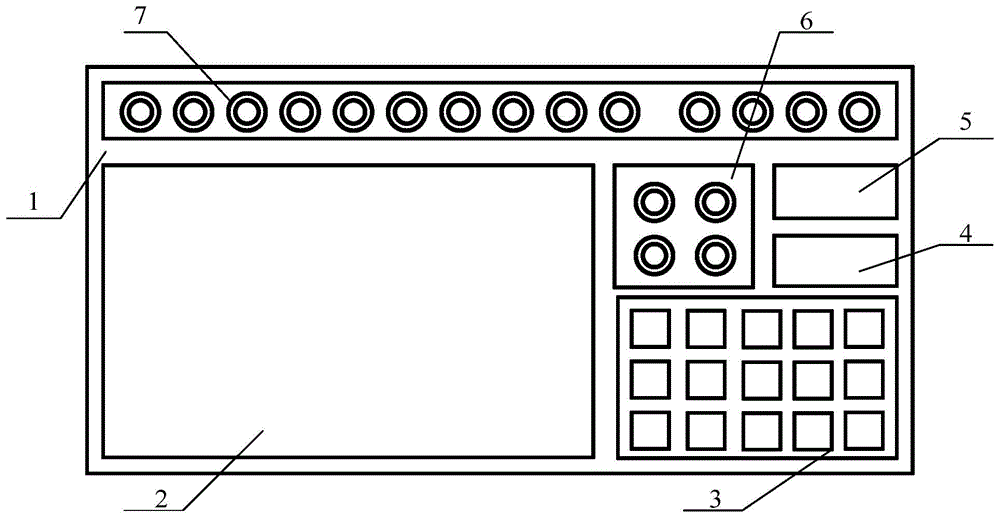

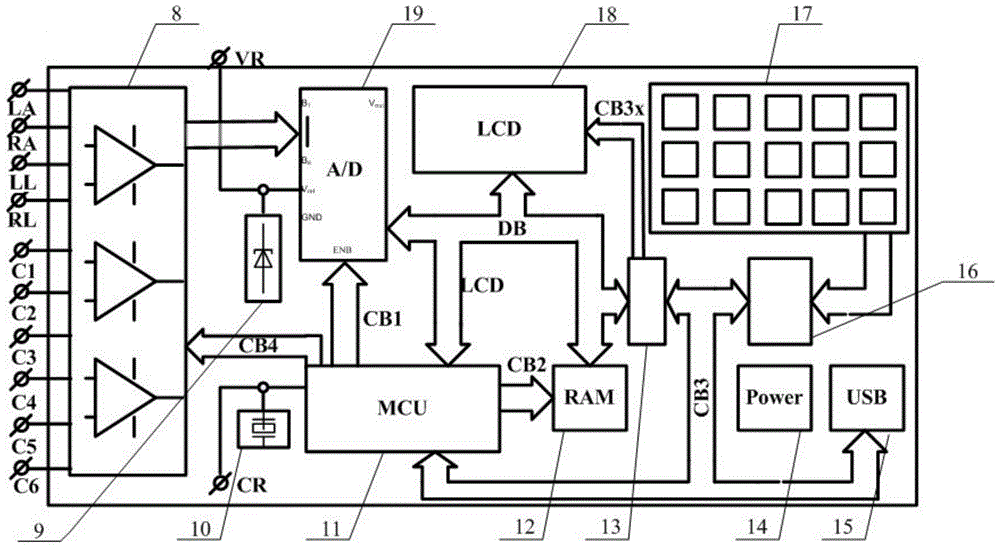

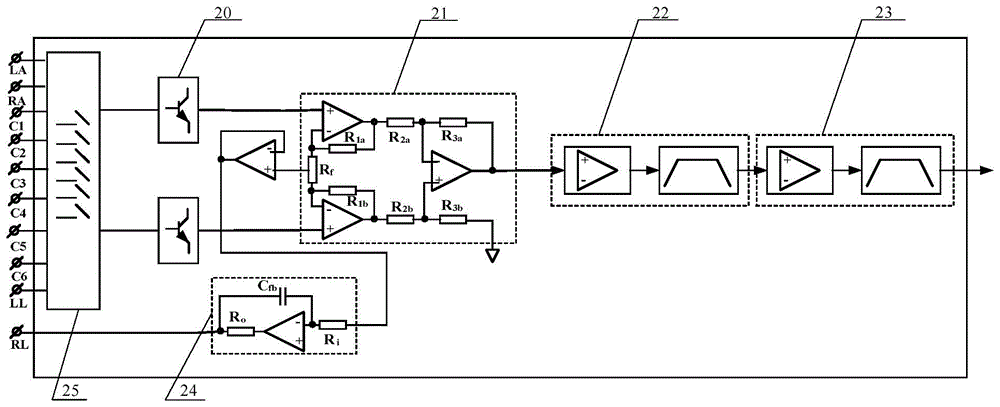

Automatic calibration device for multi-parameter physiological signal simulator

ActiveCN104013398AFull Metrology CalibrationFull traceabilitySensorsDiagnostic recording/measuringEcg signalCommunication interface

Owner:辽宁省计量科学研究院

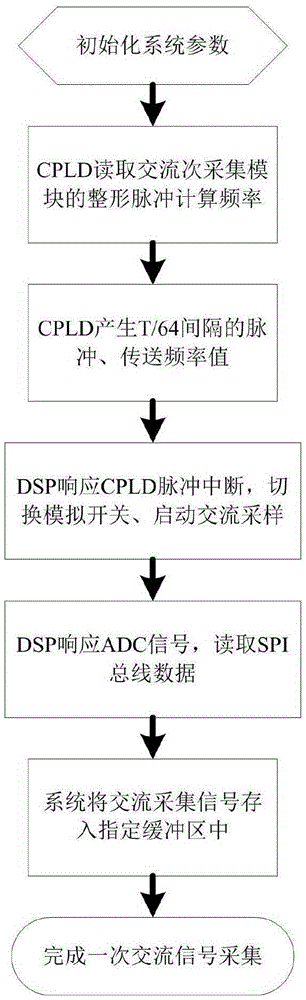

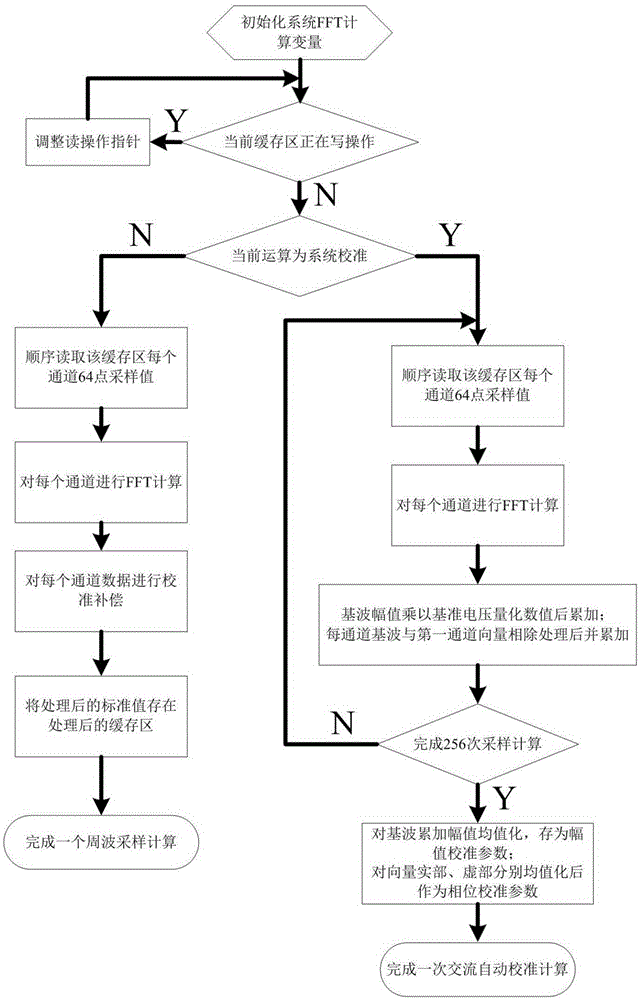

Alternating current signal collection and automatic calibration method

Owner:INTEGRATED ELECTRONICS SYST LAB

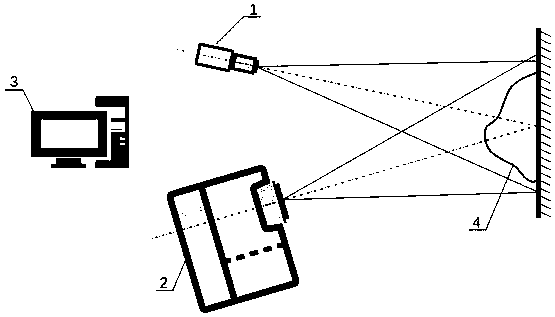

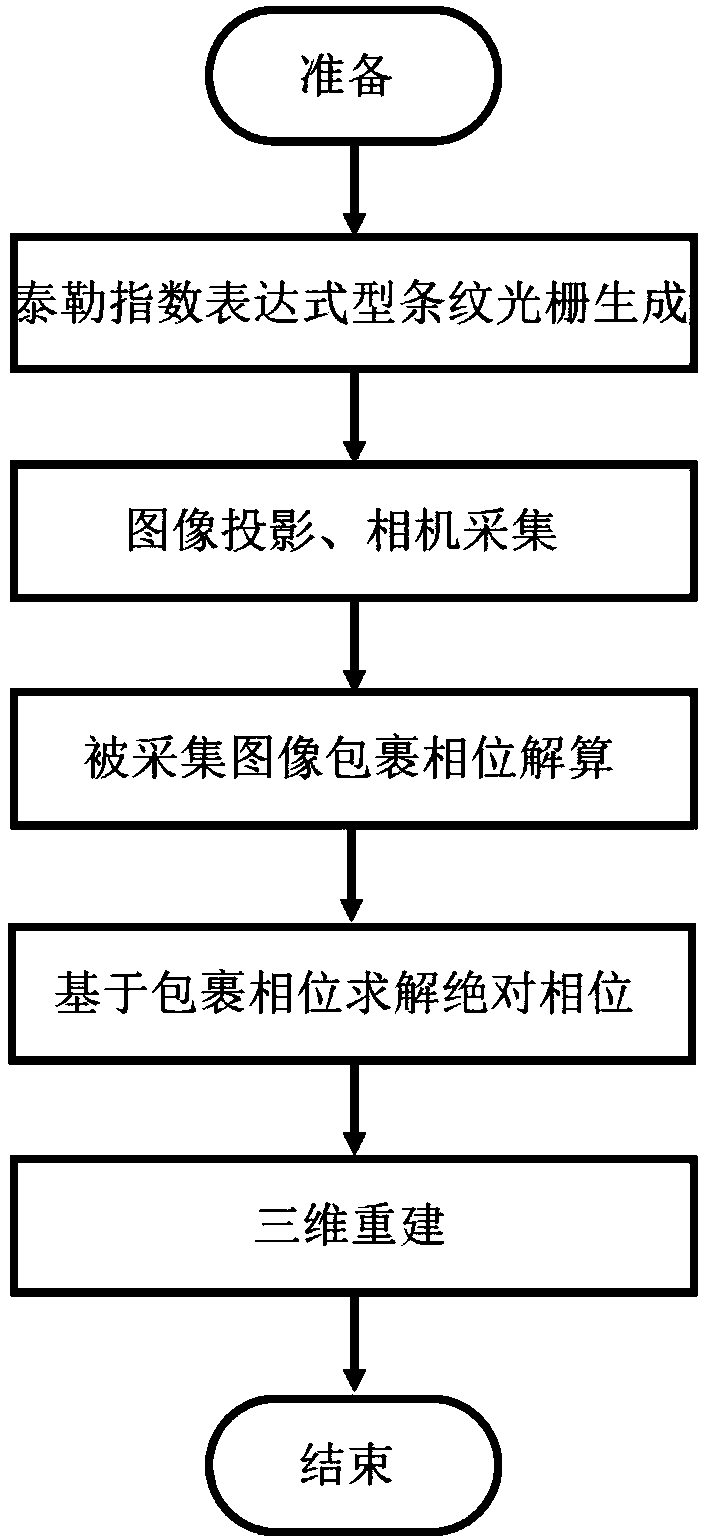

A 3-D reconstruction method based on Taylor exponent expression surface structured light

ActiveCN109523627AHigh precisionImprove accuracyDetails involving processing stepsUsing optical meansGratingReconstruction method

Owner:CHONGQING UNIV

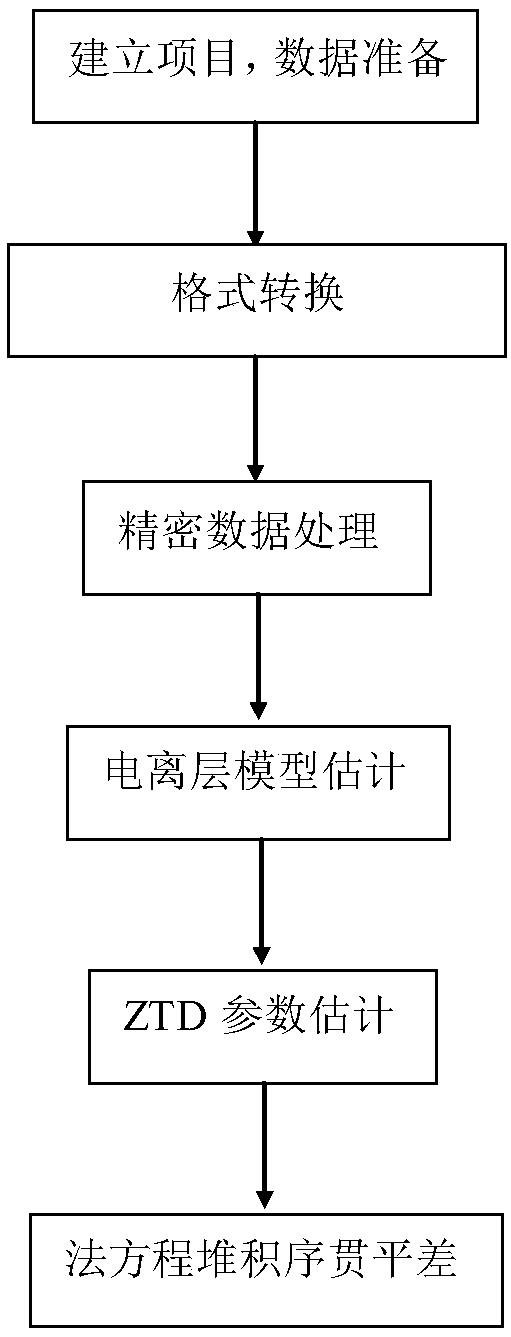

Method and device for retrieving atmospheric water vapor content

InactiveCN108828690AHigh precisionWeather condition predictionICT adaptationLiquid waterObservation data

Owner:PLA STRATEGIC SUPPORT FORCE INFORMATION ENG UNIV PLA SSF IEU

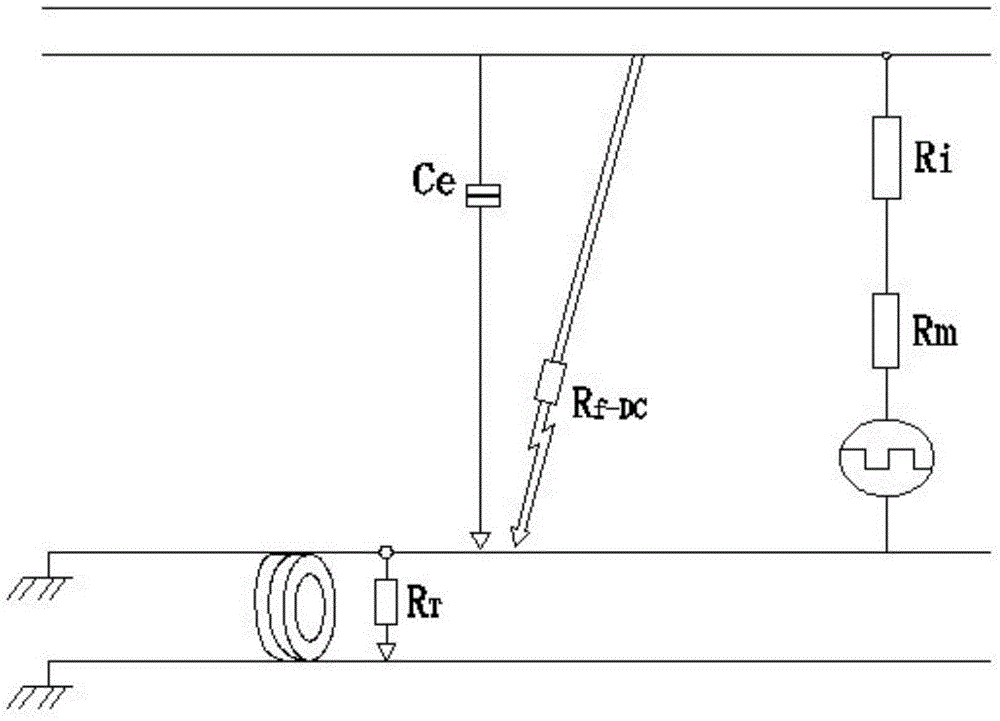

Measurement circuit and method for insulation monitoring instrument fault circuit

InactiveCN104569720AHigh measurement accuracyExtended sampling timeResistance/reactance/impedenceElectrical testingElectrical resistance and conductanceGround plane

Owner:安徽天健环保车辆部件有限公司

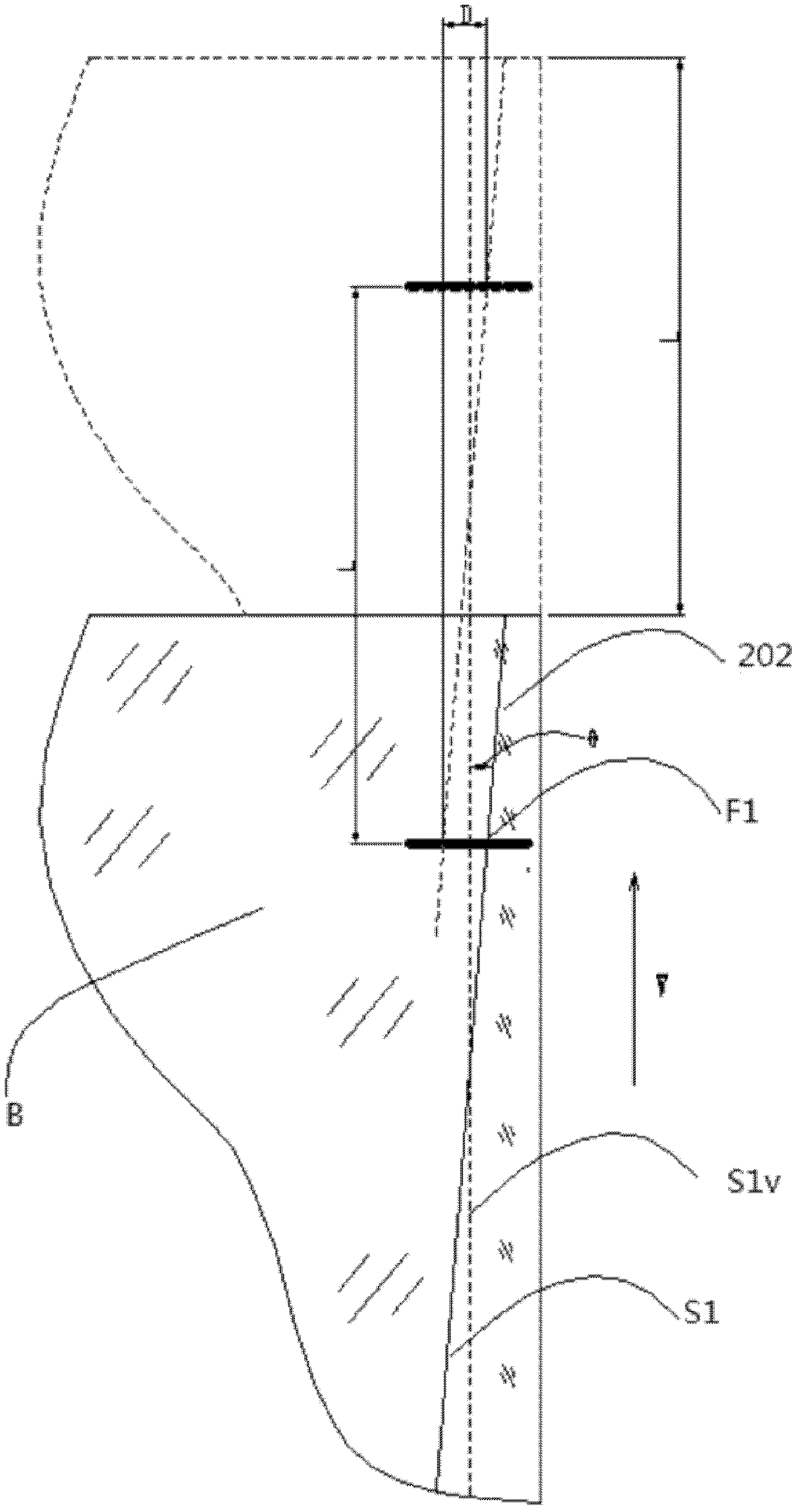

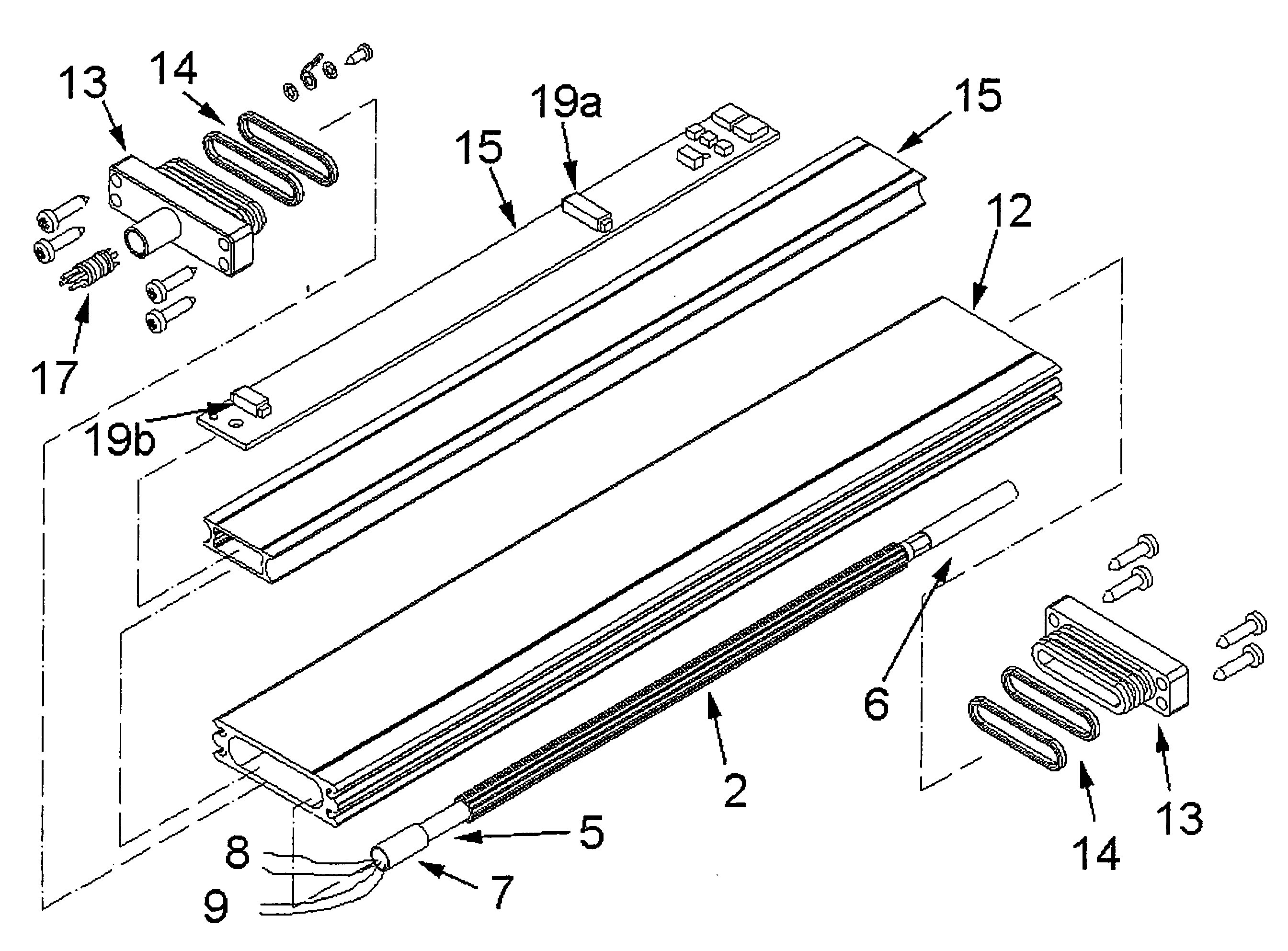

Laser measuring instrument for track lifting and lining for railway works

ActiveCN101592473AConvenient construction inspectionEasy to use and maintainTransmission systemsUsing optical meansLaser transmitterMeasurement device

The invention discloses a laser measuring instrument for track lifting and lining for railway works, which comprises a laser emitter device, a measuring device, a monitoring and correcting device and three walking trolleys. The laser emitter device, the measuring device and the monitoring and correcting device are arranged on one walking trolley respectively; the laser emitter device, the measuring device and the monitoring and correcting device are all provided with wireless communication devices and are communicated in a wireless mode; the laser emitter device comprises a track lifting laser, a track lining laser, a laser processor and a touch screen; and the measuring device and the monitoring and correcting device comprise an optical imaging system, a CCD sensor, a measuring processor, a touch screen, a horizontal sensor, and the like. The laser measuring instrument uses laser as a reference line, solves the problem of measuring the track lifting and track lining amount of long distance (more than 200 meters) in railway works department by measuring the position of the laser through the optical system and the CCD sensor, can carry out high-precision detection for railway line smoothness, provides reliable measuring basis for railway maintenance, and has high measuring precision.

Owner:JINAN LANDONG LASER TECH CO LTD

Magnetoelectric type absolute position sensor with large central hole structure and method for measuring absolute position

ActiveCN104634367ALight in massConvenient ArrangementConverting sensor output electrically/magneticallySignal processing circuitsMagnetic poles

Owner:HARBIN INST OF TECH

Laser radar transmitting system

ActiveCN109031241AHigh measurement accuracyOffset structural biasElectromagnetic wave reradiationRadar systemsLight beam

Owner:WHST CO LTD

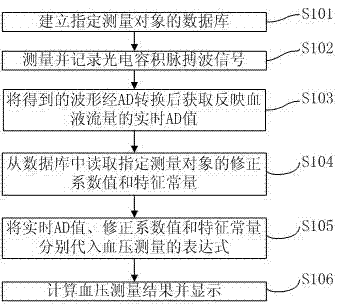

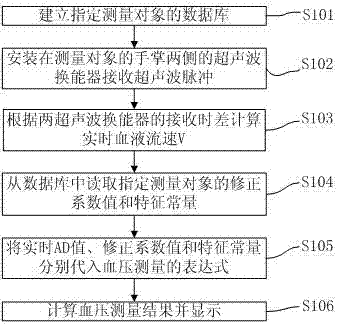

Blood pressure measurement method and system

ActiveCN103610454AReduce accidentsEliminate damageBlood flow measurement devicesAngiographyShear stressBlood pressure kit

Owner:黄志海

Dynamic strain tracing calibration method

ActiveCN110849315AEnables real-time strain measurementHigh measurement accuracyMeasurement devicesData processing systemData acquisition

The invention discloses a dynamic strain tracing calibration method, and belongs to the field of metering test. A laser vibration meter is used as a measurement means, and the measurement precision ishigh. The method comprises the steps of: starting from the definition of strain, solving an analytical solution of a first-order vibration mode of a rectangular uniform-section resonant beam, and establishing a dynamic strain calibration tracing method of a resonant beam; and obtaining standard dynamic strain data of the surface of the resonance beam through single-point measurement. The measurement process is simple, and the calibration accuracy is high. The method is achieved based on a dynamic strain tracing calibration. The calibration device comprises a vibration exciter, a resonant beam, a differential laser vibration meter, a data acquisition system, a data processing system, reflective microbeads, a strain gauge and a strain demodulator. According to the invention, the surface vibration displacement of the resonant beam is measured, and then the surface dynamic strain distribution of the resonant beam is obtained through data processing. The method is not limited by a resonantbeam structure and an installation form, real-time strain data of the surface of the beam can be obtained, and dynamic strain tracing calibration is achieved.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

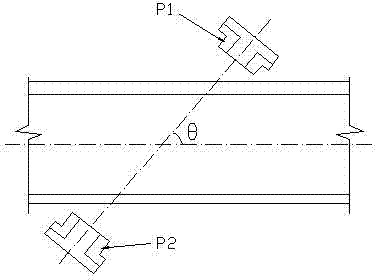

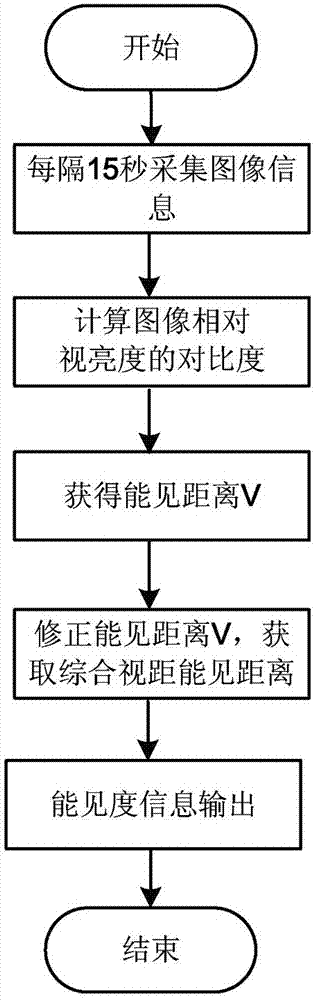

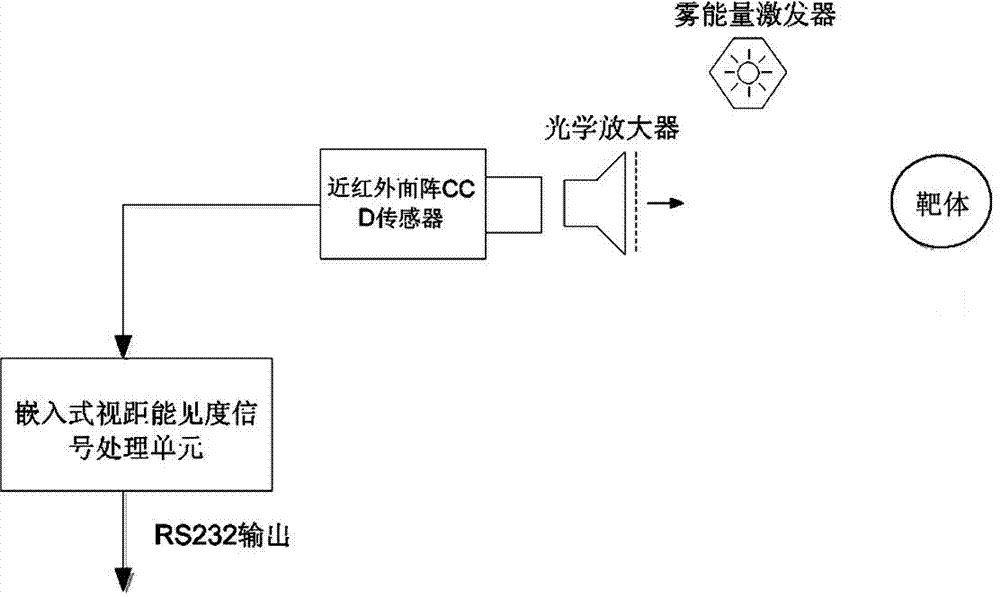

Sight distance visibility meter and measuring method thereof

InactiveCN104777103ASimple structureLow costMaterial analysis by optical meansActuatorMeasurement precision

Owner:XIAN HAO TONG ENERGY SAVING ENG EQUIP

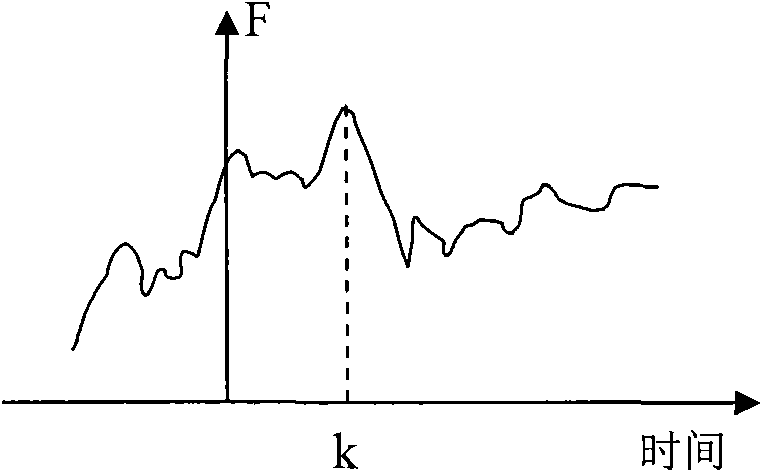

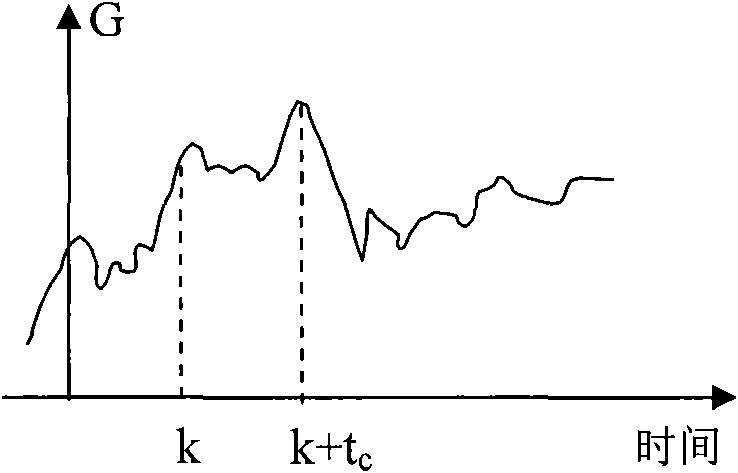

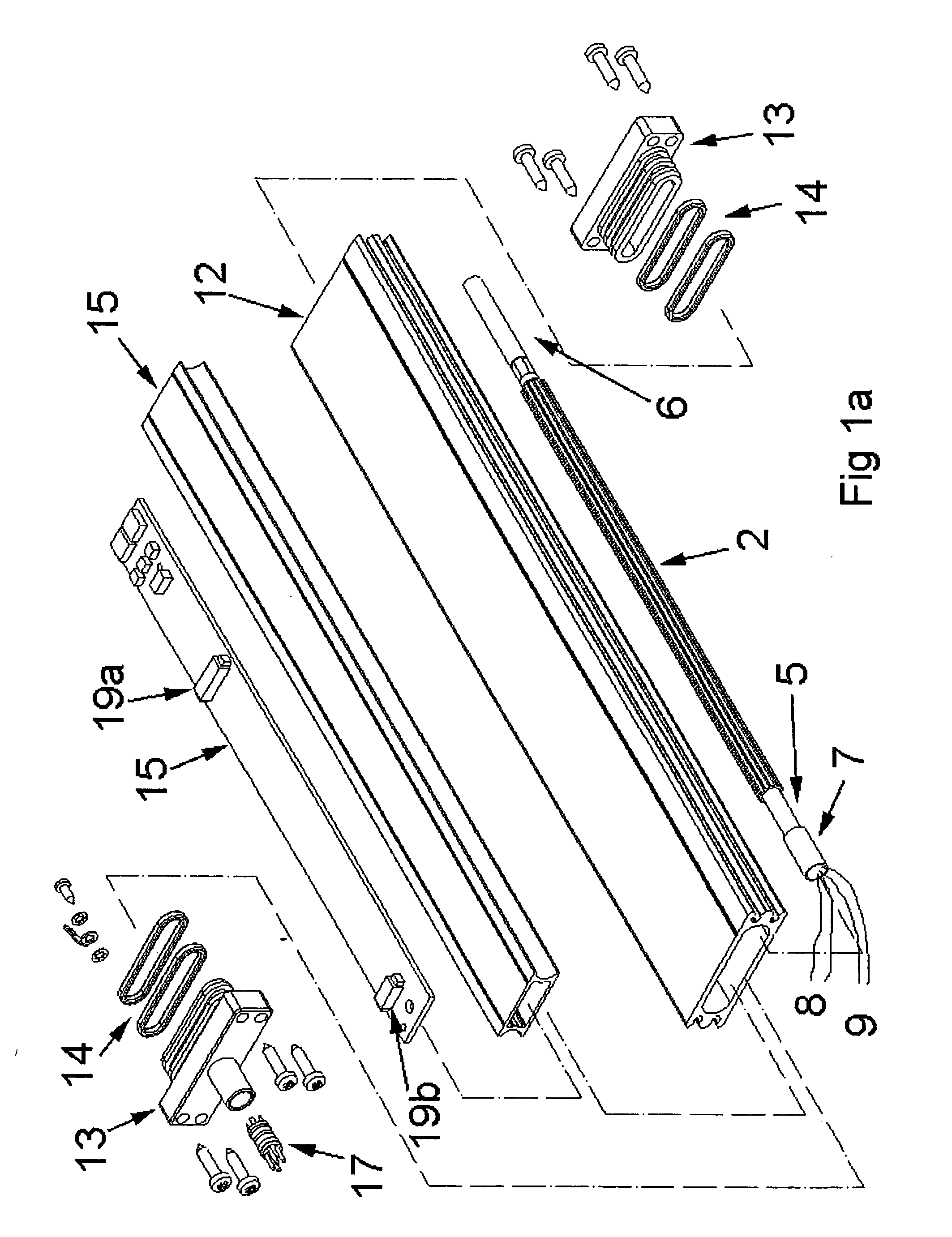

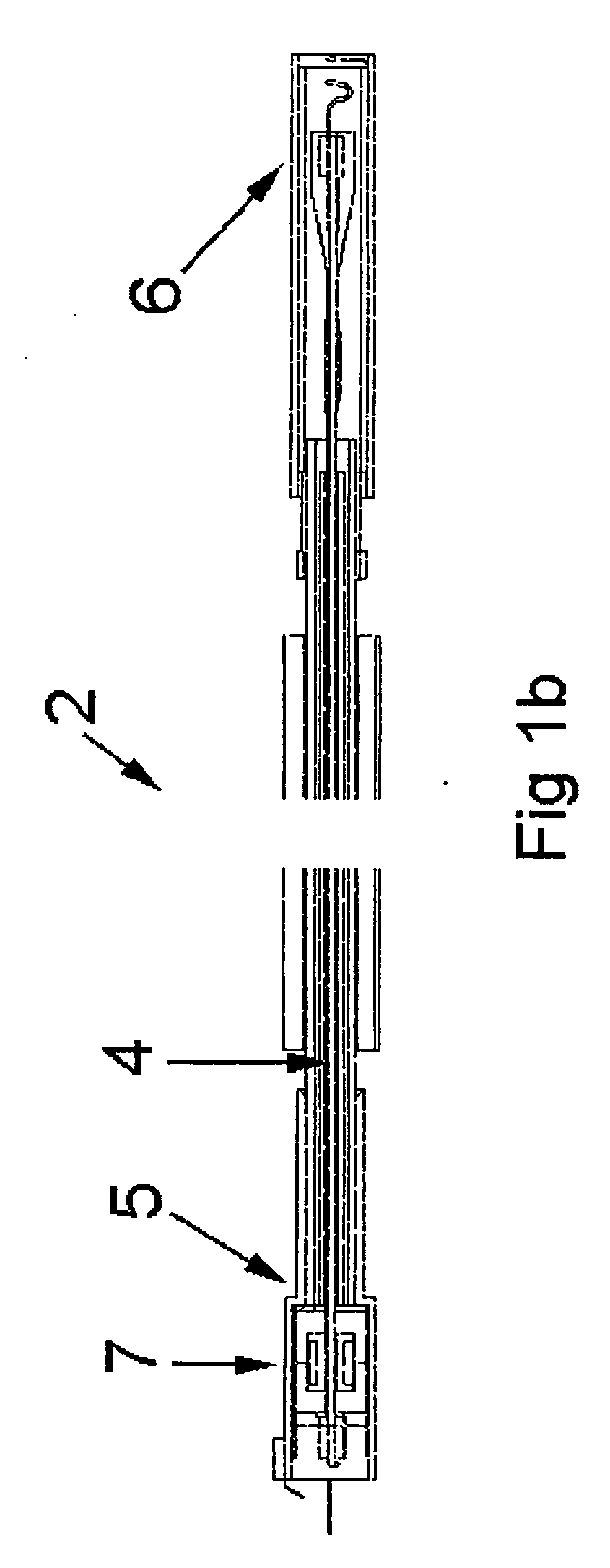

Process for determining a time interval

InactiveUS20070085726A1Using electrical meansConverting sensor outputEngineeringMeasurement precision

Owner:ASM AUTOMATION SENSORIK MESSTECHN GMBH

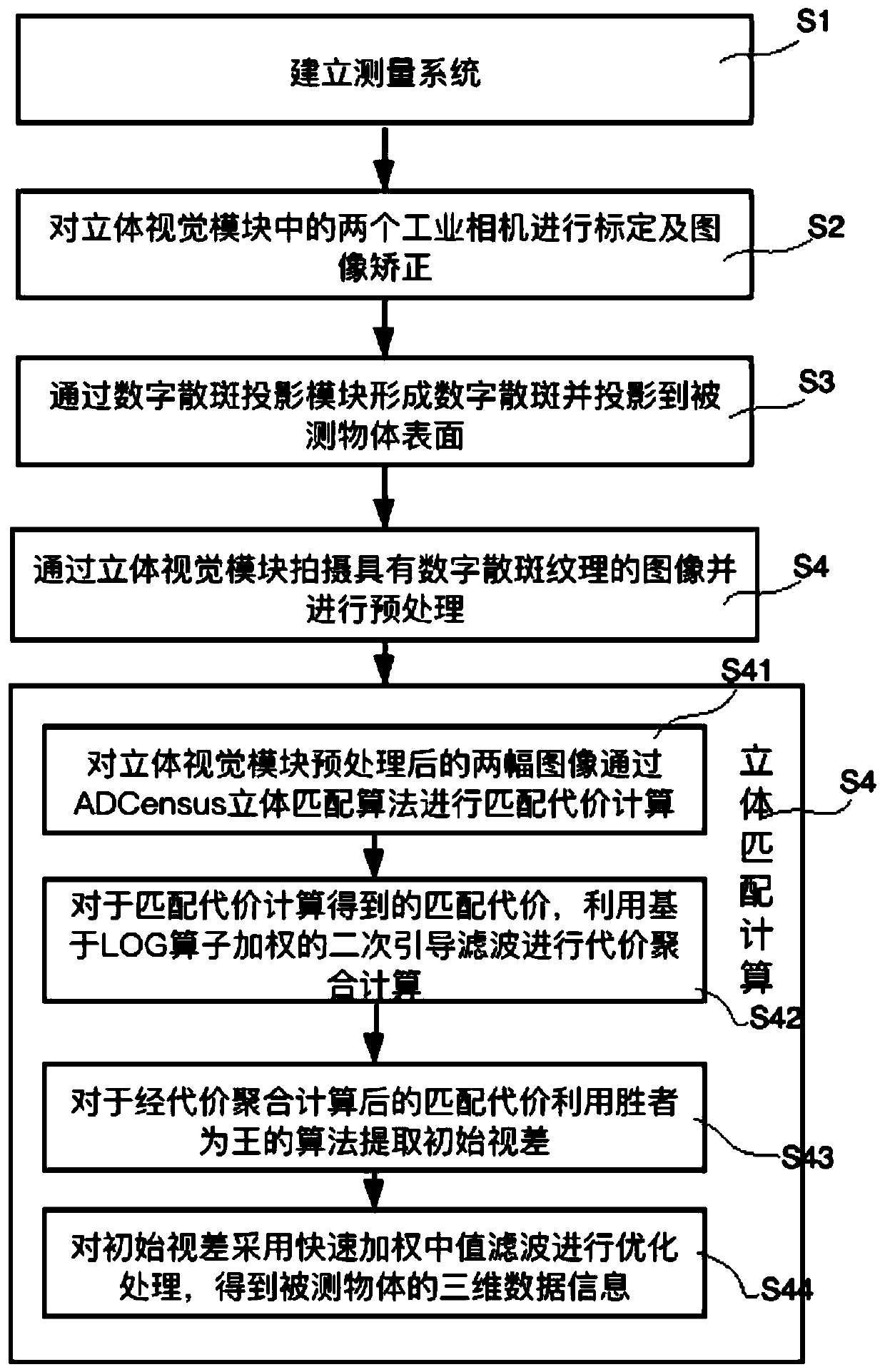

Stereo matching method based on cost aggregation

InactiveCN111351449ANot easy to influenceHigh measurement accuracyImage analysisUsing optical meansCost aggregationComputer graphics (images)

Owner:GUANGDONG UNIV OF TECH

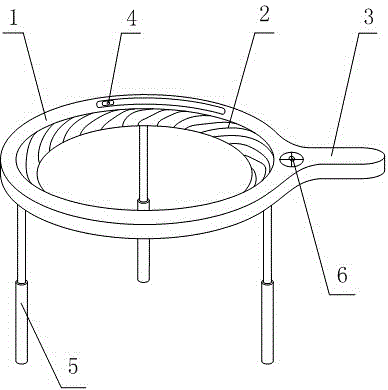

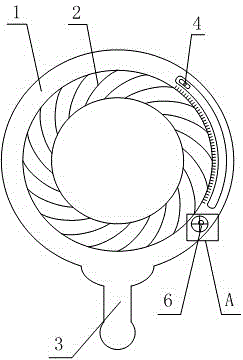

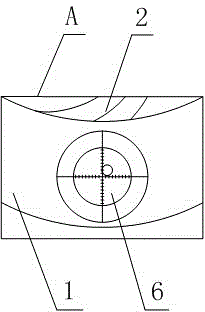

Floor lifting horizontal bit gauge

InactiveCN105547100APlace stableAvoid an unstable gripMechanical diameter measurementsMeasurement precisionComputer engineering

Owner:CHENGDU LIXIN SCI & TECH

Elevator counterweight guide rail guidance stroke measurement device based on sensor technology

ActiveCN111362088AImprove the level of inspection scienceSolve the difficulty of measurementElevatorsLaser rangingRemote control

The invention discloses an elevator counterweight guide rail guidance stroke measurement device based on the sensor technology. The device comprises a measurement robot and a remote control box. The distance between the machine body of the measurement robot and a guidance surface of a guide rail is measured in real time through a Hall sensor on the robot. The distance between the top of the counterweight guide rail and an elevator counterweight side oil cup is measured through a laser distance sensor. Then the guide rail guidance stroke of when a buffer is completely compressed by an elevatoris measured. According to the elevator counterweight guide rail guidance stroke measurement device based on the sensor technology, a method is high in measurement accuracy and quick in measurement, the problem that it is difficult to measure the guide rail guidance stroke is solved, the measurement accuracy of the guide rail guidance stroke is greatly improved, the checking science level of a checking mechanism is improved as well, and powerful technology support is provided for guaranteeing elevator operation security.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

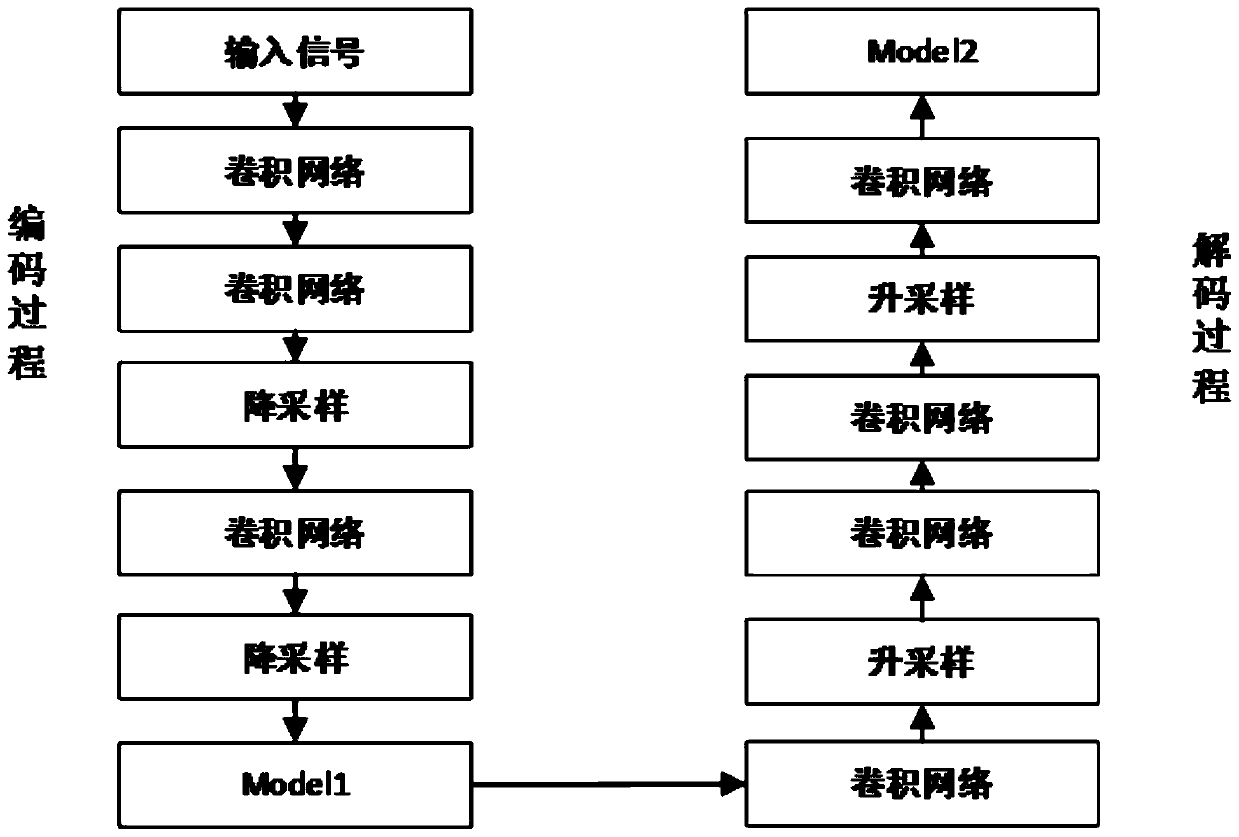

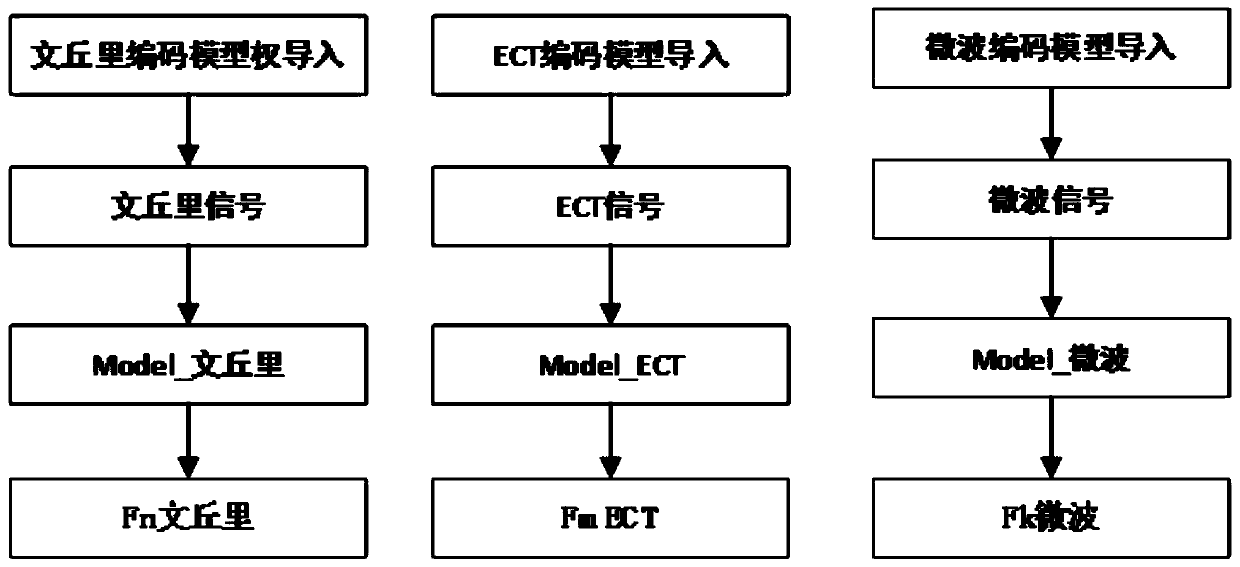

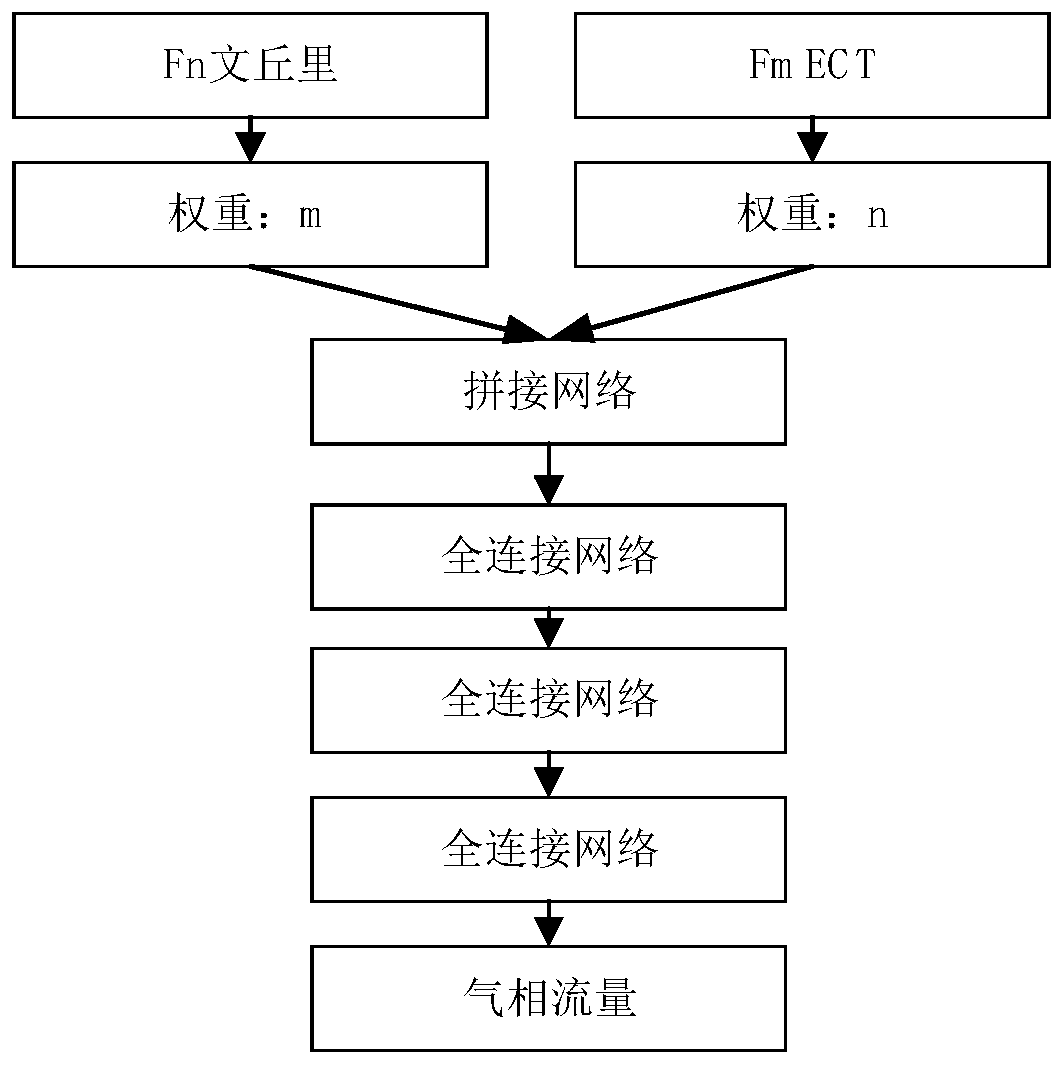

Multiphase flow online real-time metering artificial intelligence model construction method

ActiveCN111460625AReduce complexityHigh measurement accuracyDesign optimisation/simulationNeural architecturesControl engineeringCoding decoding

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

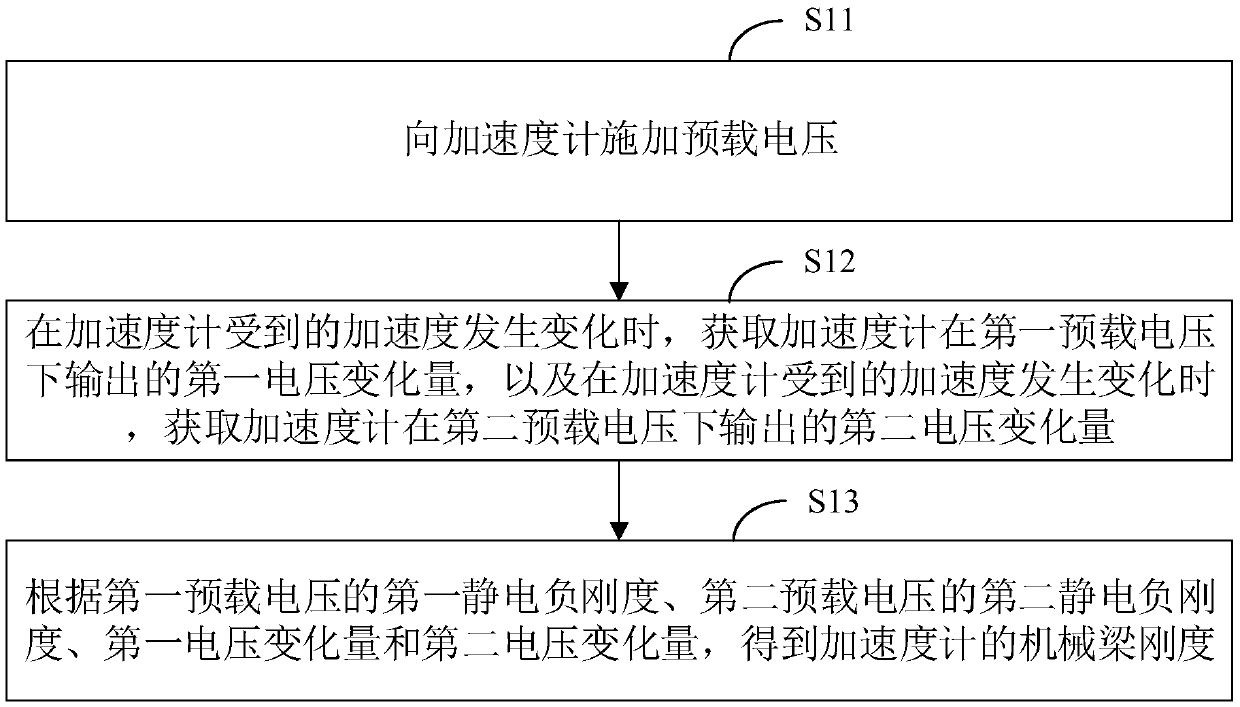

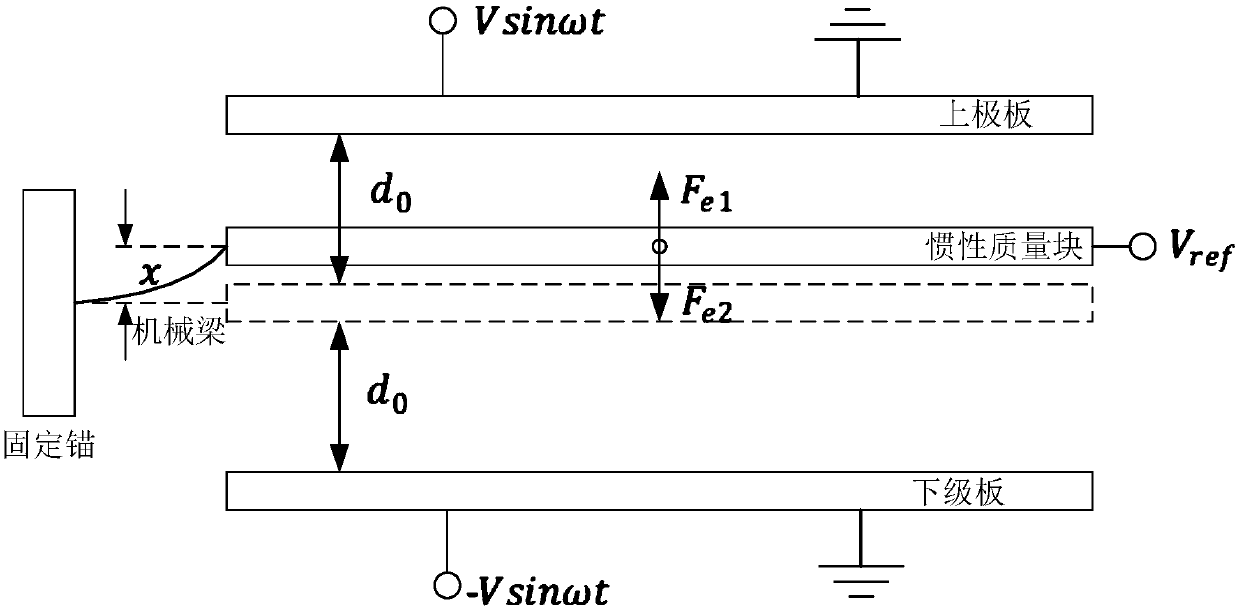

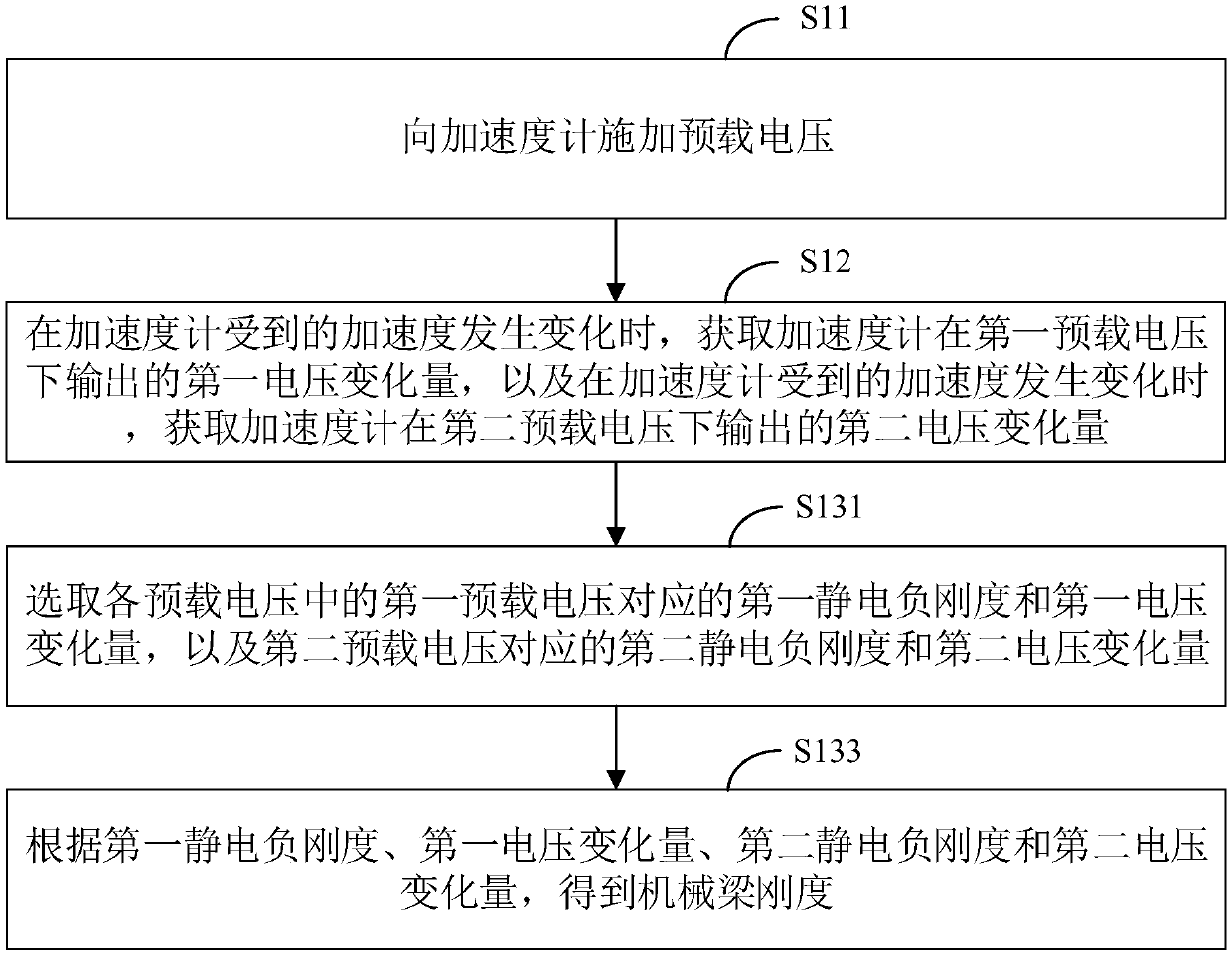

Method, device and system for measuring mechanical beam rigidity of capacitive MEMS accelerometer

ActiveCN109613302AInfluence of measurement accuracyHigh measurement accuracyAcceleration measurementTesting/calibration of speed/acceleration/shock measurement devicesInertial massConversion coefficients

Owner:CHINA ELECTRONICS PROD RELIABILITY & ENVIRONMENTAL TESTING RES INST

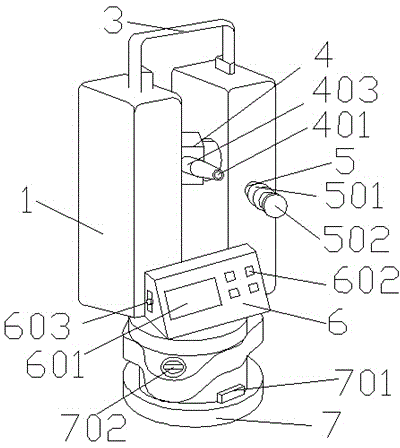

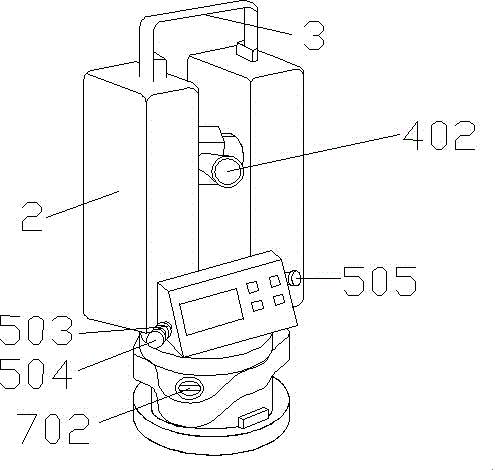

Photoelectric-technology-based construction engineering surveying equipment

InactiveCN105627999ASimple structureEasy to operateSurveying instrumentsTheodolitesArchitectural engineeringComputer module

Owner:HENAN UNIVERSITY OF TECHNOLOGY

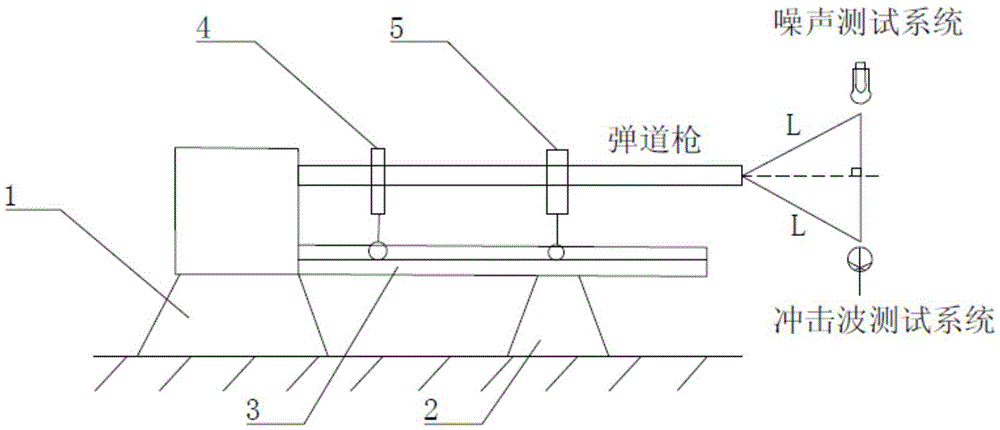

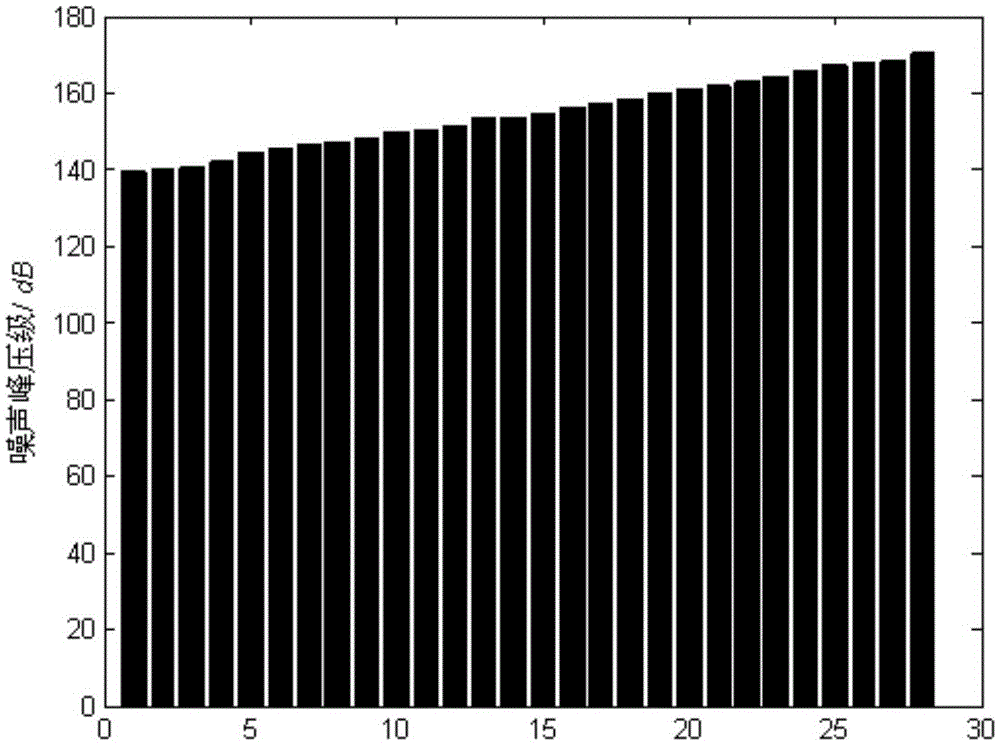

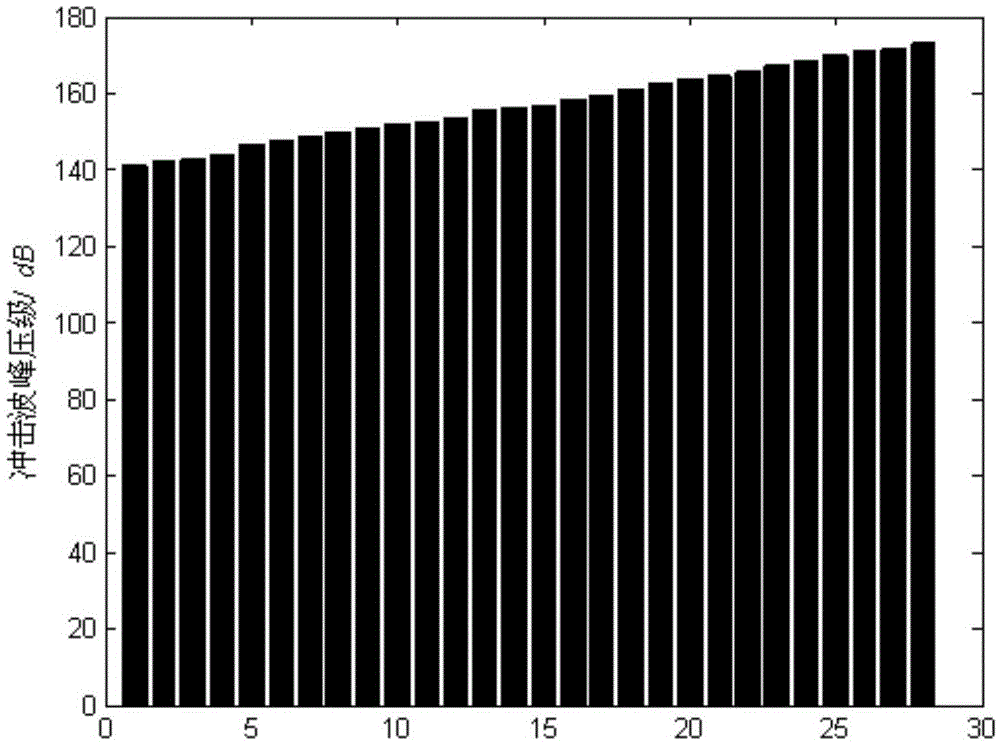

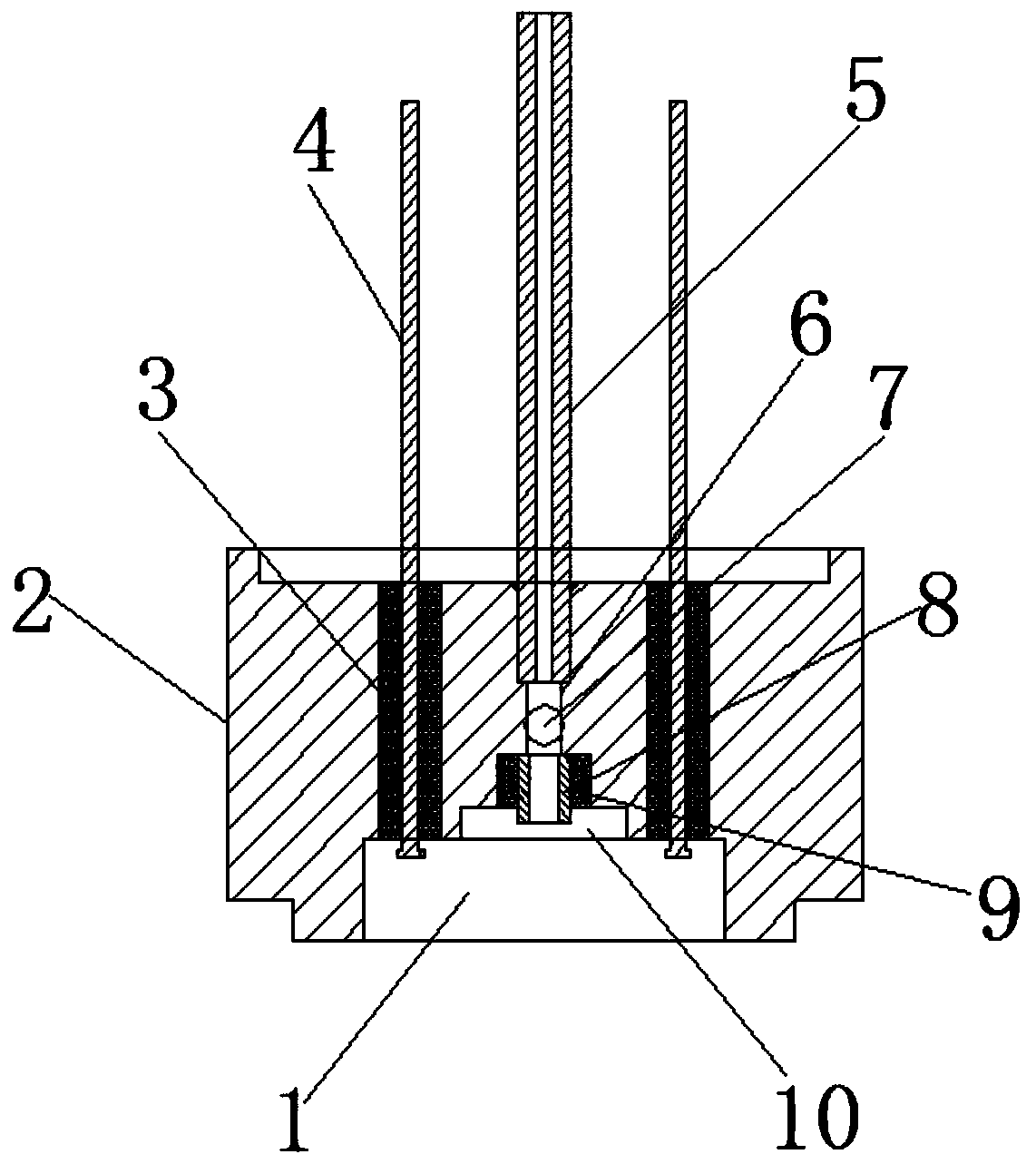

Comparison-type calibration method for shock wave measurement

InactiveCN105486452AAvoid insecurityGuaranteed Calibration AccuracyFluid pressure measurementShock waveEngineering

Owner:张宇峰

Sensor base for reducing stress of shell on chip

ActiveCN110567638AFluid pressure measurementMeasurement precisionElectrical and Electronics engineering

Owner:BENGBU CHUANGYE ELECTRONICS

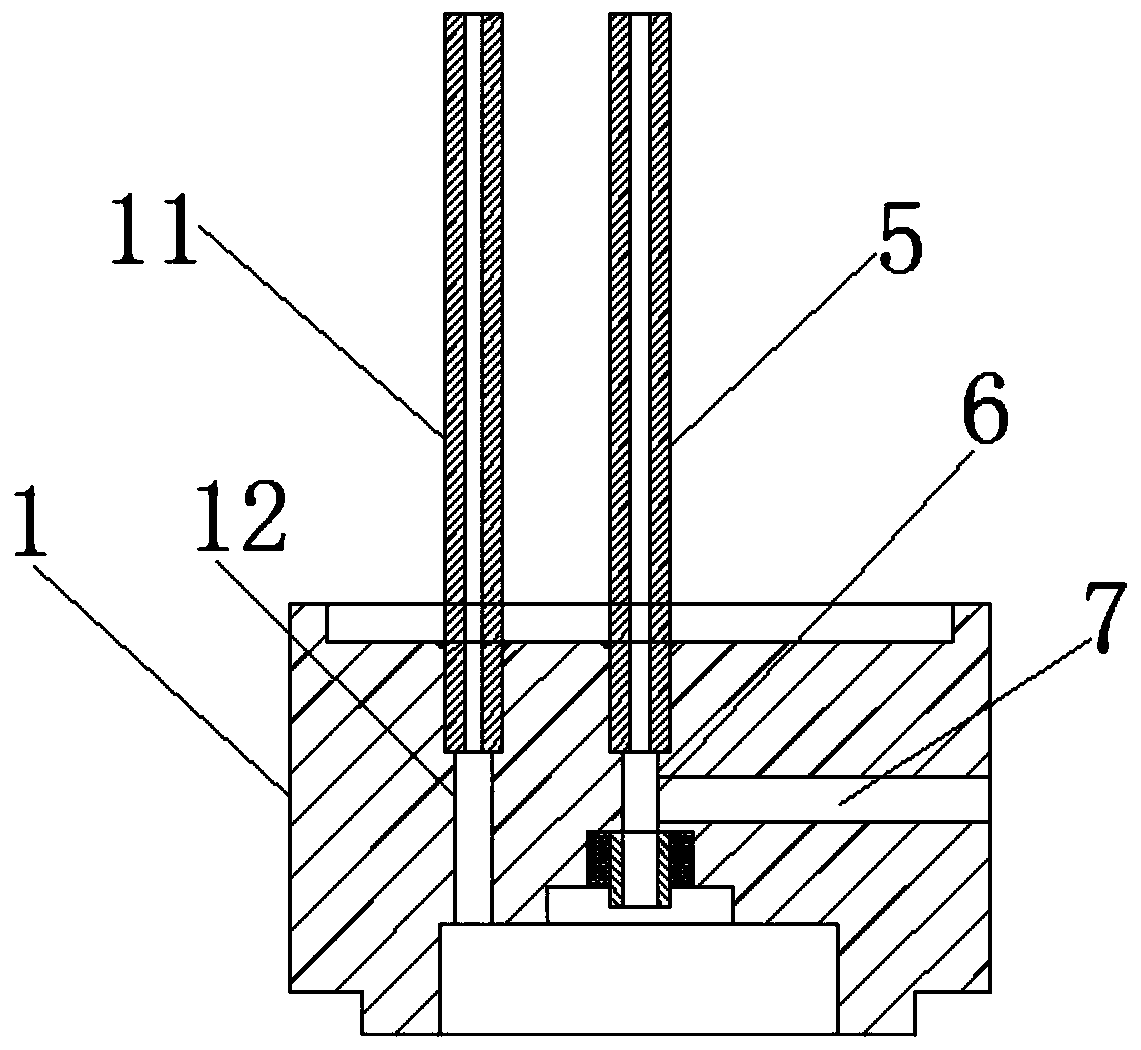

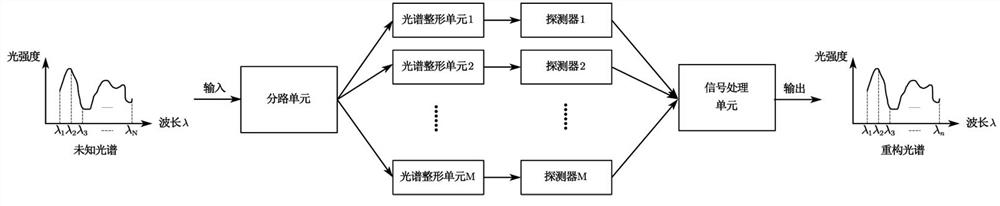

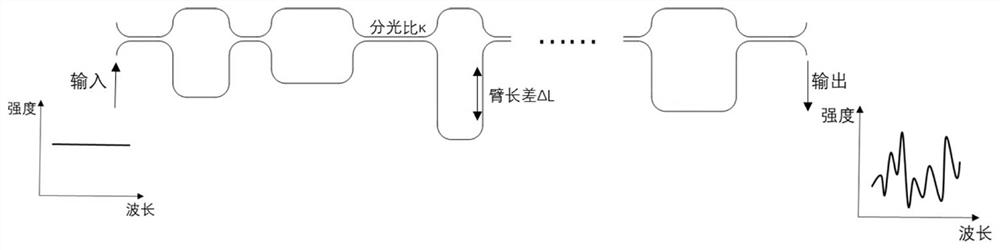

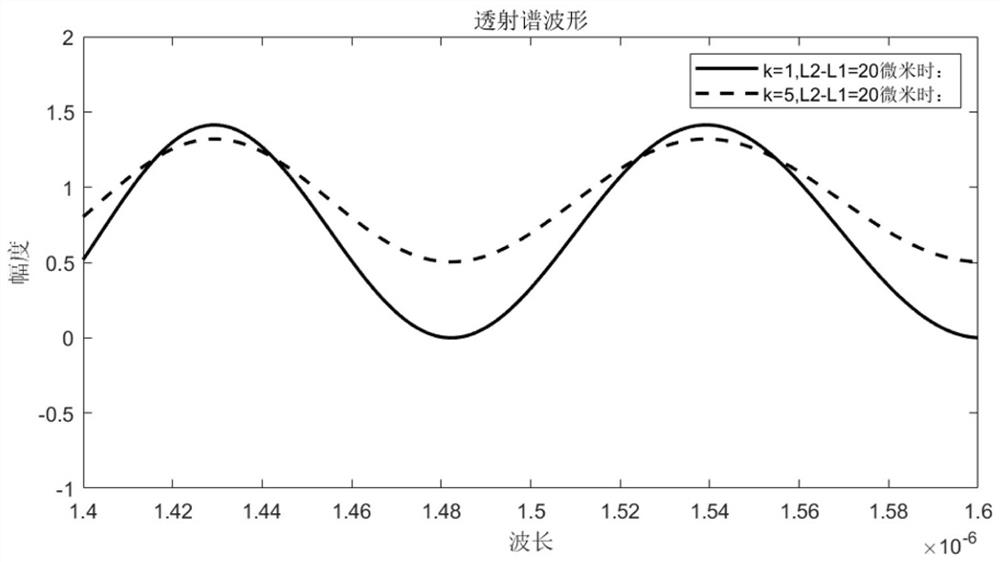

Broadband spectrum shaping device and calculation type spectrum measuring device

PendingCN114441037AImprove process precisionHigh precisionRadiation pyrometrySpectrum investigationGratingScattering loss

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Linear measurement control method for multi-curved-surface distorted steel tower

ActiveCN108733950AControl manufacturing precisionSmall sizeGeometric CADDesign optimisation/simulationLinear controlEngineering

The invention discloses a linear measurement control method for a multi-curved-surface distorted steel tower. The method comprises the following steps of (1) drawing a steel tower three-dimensional model to obtain a design steel tower 1:1 model; (2) selecting representative characteristic point three-dimensional data as a measurement control point on the model according to structural characteristics of steel tower sections; (3) establishing a construction measurement control net at a steel tower section or steel tower pre-assembly manufacturing site; (4) measuring the steel tower sections, fitting measurement data and three-dimensional model data of the steel tower sections, obtaining a deviation, and according to the deviation, adjusting the steel tower sections to meet design and standard requirements; (5) pre-assembling the steel tower sections, and adjusting the pre-assembled steel tower sections to meet the design and standard requirements; and (6) assembling the adjusted pre-assembled steel tower sections into the steel tower. According to the method, a traditional steel structure machining and manufacturing method based on auxiliary baseline drawing and steel disc ruler measurement is changed; the production efficiency and the measurement precision are improved; the labor cost is reduced; a basis can be provided for bridge location erection; and the convenience is provided for erection linear control of a bridge location erection monitoring unit.

Owner:CHINA RAILWAY BAOJI BRIDGE YANGZHOU CO LTD +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap