Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Vibration exciter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

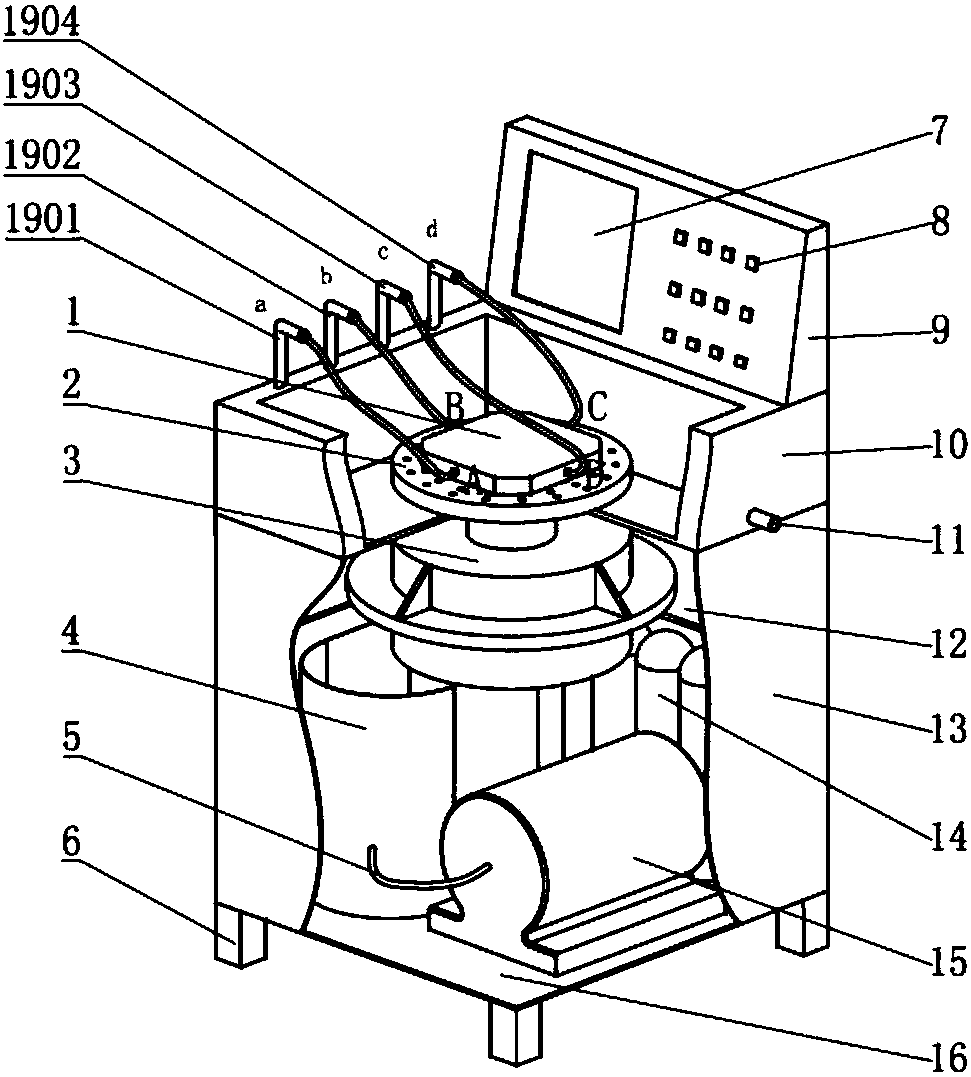

Dynamic strain tracing calibration method

ActiveCN110849315AEnables real-time strain measurementHigh measurement accuracyMeasurement devicesData processing systemData acquisition

The invention discloses a dynamic strain tracing calibration method, and belongs to the field of metering test. A laser vibration meter is used as a measurement means, and the measurement precision ishigh. The method comprises the steps of: starting from the definition of strain, solving an analytical solution of a first-order vibration mode of a rectangular uniform-section resonant beam, and establishing a dynamic strain calibration tracing method of a resonant beam; and obtaining standard dynamic strain data of the surface of the resonance beam through single-point measurement. The measurement process is simple, and the calibration accuracy is high. The method is achieved based on a dynamic strain tracing calibration. The calibration device comprises a vibration exciter, a resonant beam, a differential laser vibration meter, a data acquisition system, a data processing system, reflective microbeads, a strain gauge and a strain demodulator. According to the invention, the surface vibration displacement of the resonant beam is measured, and then the surface dynamic strain distribution of the resonant beam is obtained through data processing. The method is not limited by a resonantbeam structure and an installation form, real-time strain data of the surface of the beam can be obtained, and dynamic strain tracing calibration is achieved.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

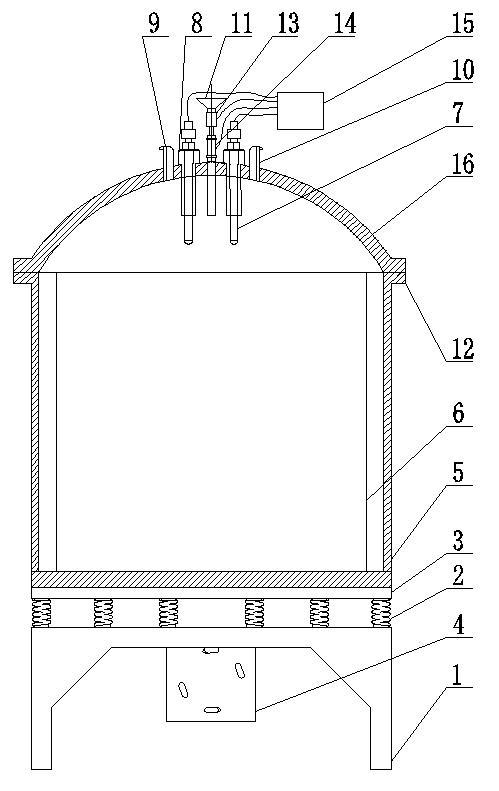

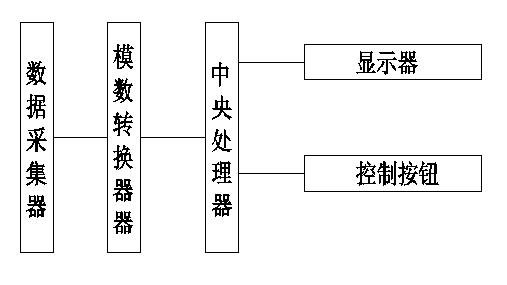

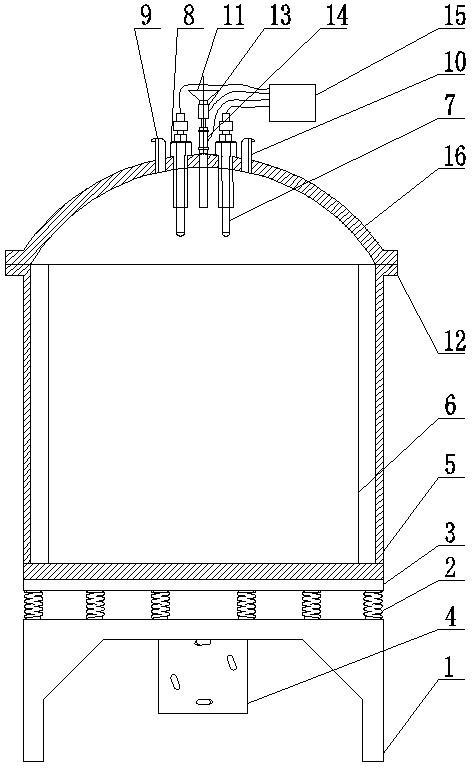

Automatic control multifunctional reactor

InactiveCN102688740AAvoid harmPrecise temperature controlShaking/oscillating/vibrating mixersChemical/physical/physico-chemical moving reactorsChemical reactionAutomatic control

Owner:NANJING BAIYUN CHEM ENVIRONMENTAL MONITORING

Coking feeding equipment for convenient for pretreatment and controllable in feeding speed

InactiveCN112552930AEasy pretreatmentFeeding speed is controllableCharging devicesGear wheelControl theory

The invention discloses coking feeding equipment convenient for pretreatment and controllable in feeding speed. The equipment comprises a box body, a limiting rod and a second air cylinder, a feedingbin is fixedly connected to the right side of the box body, a screw rod is connected to the inner side of the feeding bin in an attached mode, and a gear rod is connected to the inner side of the upper end of the box body in a clamped mode, a belt is connected to the outer side of the front end of the gear rod in an attached mode, a supporting plate is arranged on the lower side of the gear rod, avibration exciter is installed on the inner side of the middle of the supporting plate, a filtering plate is connected to the upper side of the vibration exciter in an attached mode, and a limiting block is fixedly connected to the lower side of the outer end of the filtering plate, a fixing block is fixedly connected to the left side of the upper end of the box body, and the inner side of the fixing block is rotationally connected with a box cover. According to the coking feeding equipment convenient for pretreatment and controllable in feeding speed, charging and feeding are facilitated, raw materials are conveniently subjected to crushing, filtering and mixing pretreatment, the feeding amount and the feeding speed are conveniently controlled, and the filtering plate is conveniently disassembled and cleaned.

Owner:XINXIANG BENUO ELECTRONIC INFORMATION TECH CO LTD

Automatic cleaning device for 3D printing cold plate runner

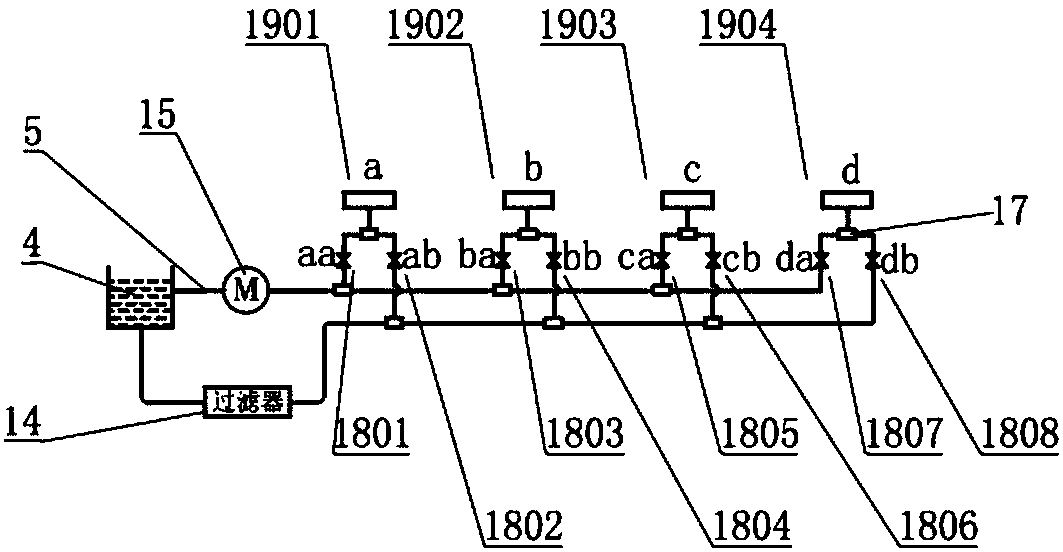

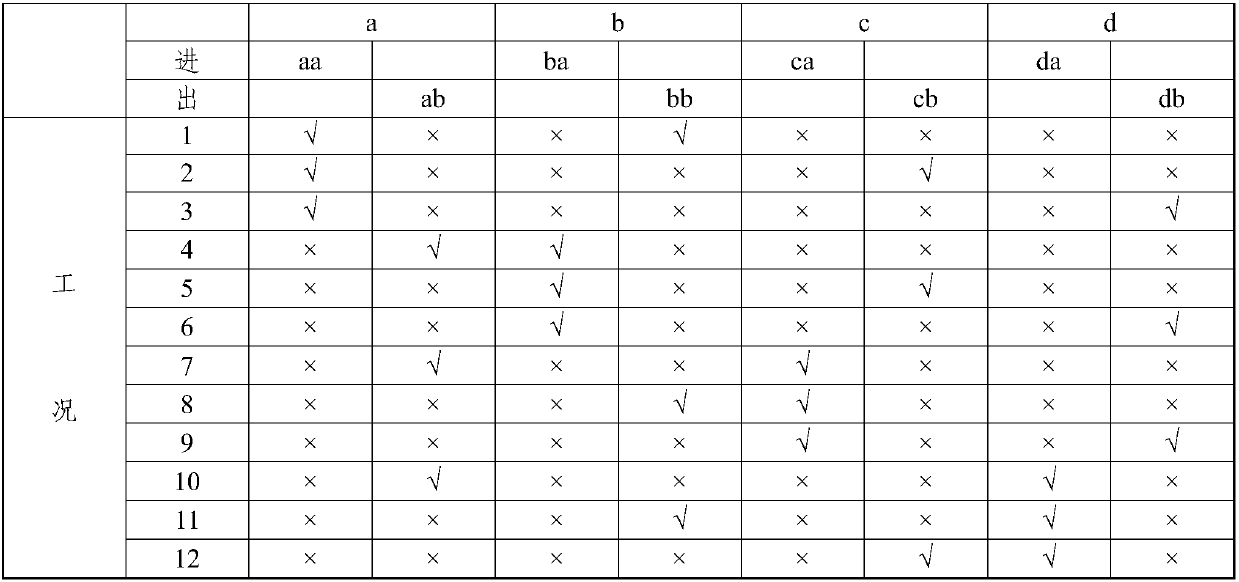

InactiveCN108015277AGuaranteed cleaning qualityReduce volumeAdditive manufacturing apparatusIncreasing energy efficiencyWater flowLiquid storage tank

Owner:BEIJING INST OF REMOTE SENSING EQUIP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap