Diamond drill bit suitable for hard stratum drilling

A technology for diamond drill bits and hard formations, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of poor drill bit working conditions, affecting drilling efficiency, damage to downhole tools and measuring instruments, etc., to reduce axial vibration and Torsional vibration phenomenon, reduced polygon effect, enhanced self-righting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

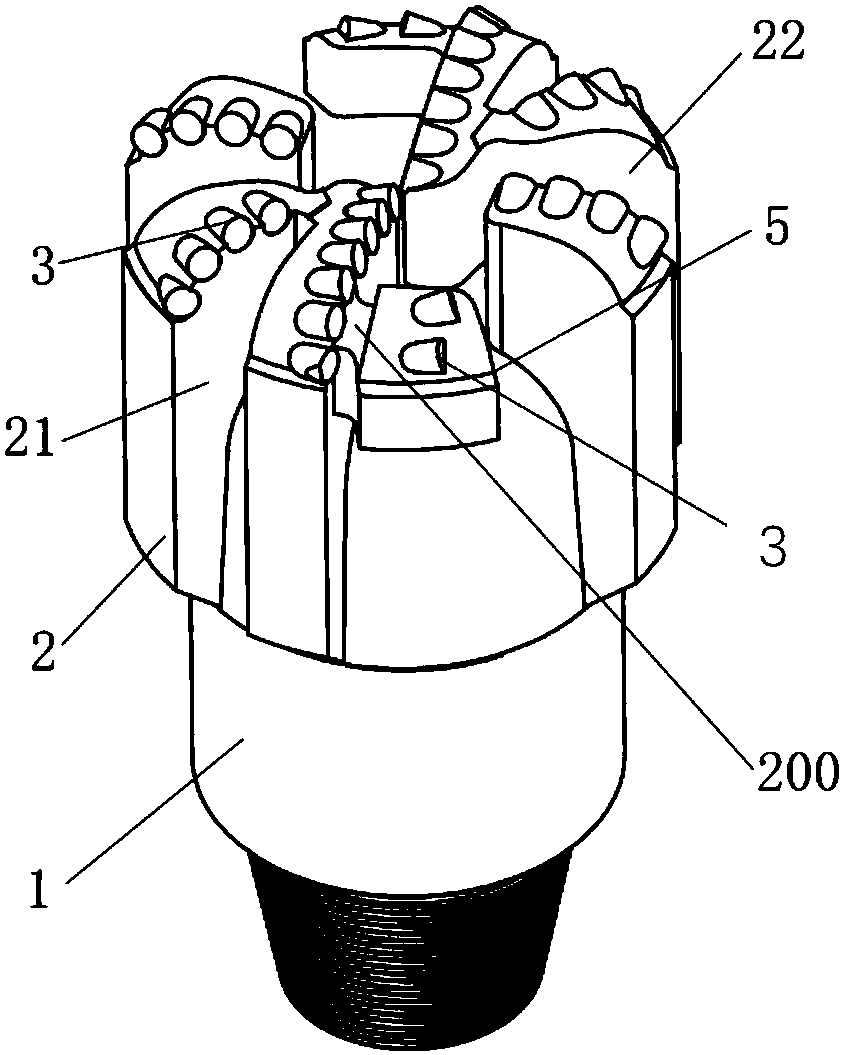

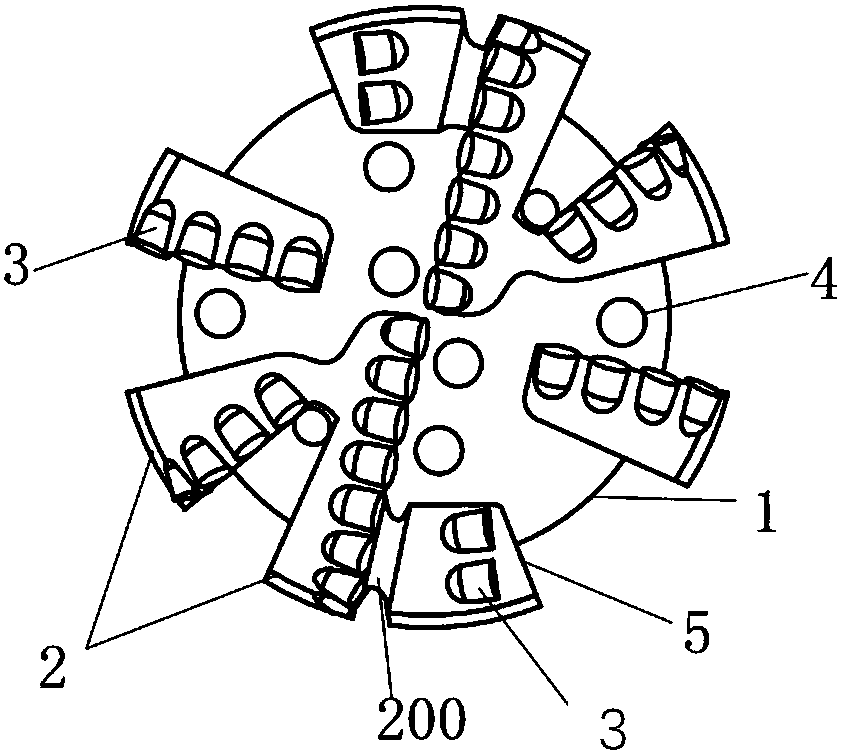

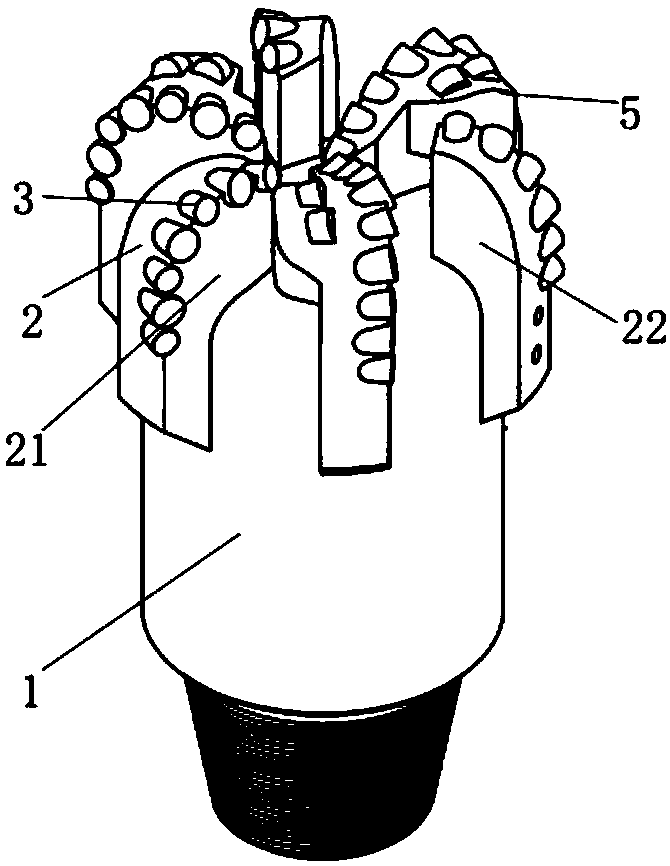

[0048] Embodiments of the present invention provide a diamond drill bit suitable for drilling in hard formations, please refer to Figure 1-9 Part of the possible implementation of the present invention, including a drill body 1, several blades 2, water holes or nozzles 4 extending from the drill body 1 or fixed on the drill body 1, the blades are provided with scraping teeth 3, At least one blade 2 is extended with a reinforcing seat 5 in the circumferential direction of the drill bit, and the scraping teeth 3 installed through tooth sockets are arranged on the reinforcing seat.

[0049] The drill bit also includes a drill bit axis. During the rock breaking process, the drill bit can rotate around the drill bit axis to make the scraping teeth 3 on the blade 2 move relative to the rock, thereby breaking the rock. The broken rock is carried into the annulus by the drilling fluid through the cutting groove.

[0050] The shape of the working face of the scraping tooth 3 is a plane

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap