Method and apparatus for using dual parallel NOx traps for diesel emissions reduction

a technology of nox traps and traps, which is applied in the direction of mechanical apparatus, machines/engines, engine components, etc., can solve the problems of reducing adsorption effectiveness for a period of time, nox may be hazardous to health, and the required catalyst volume is twice the required volume, so as to reduce the cooling of the traps, and reduce the effect of nox traps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

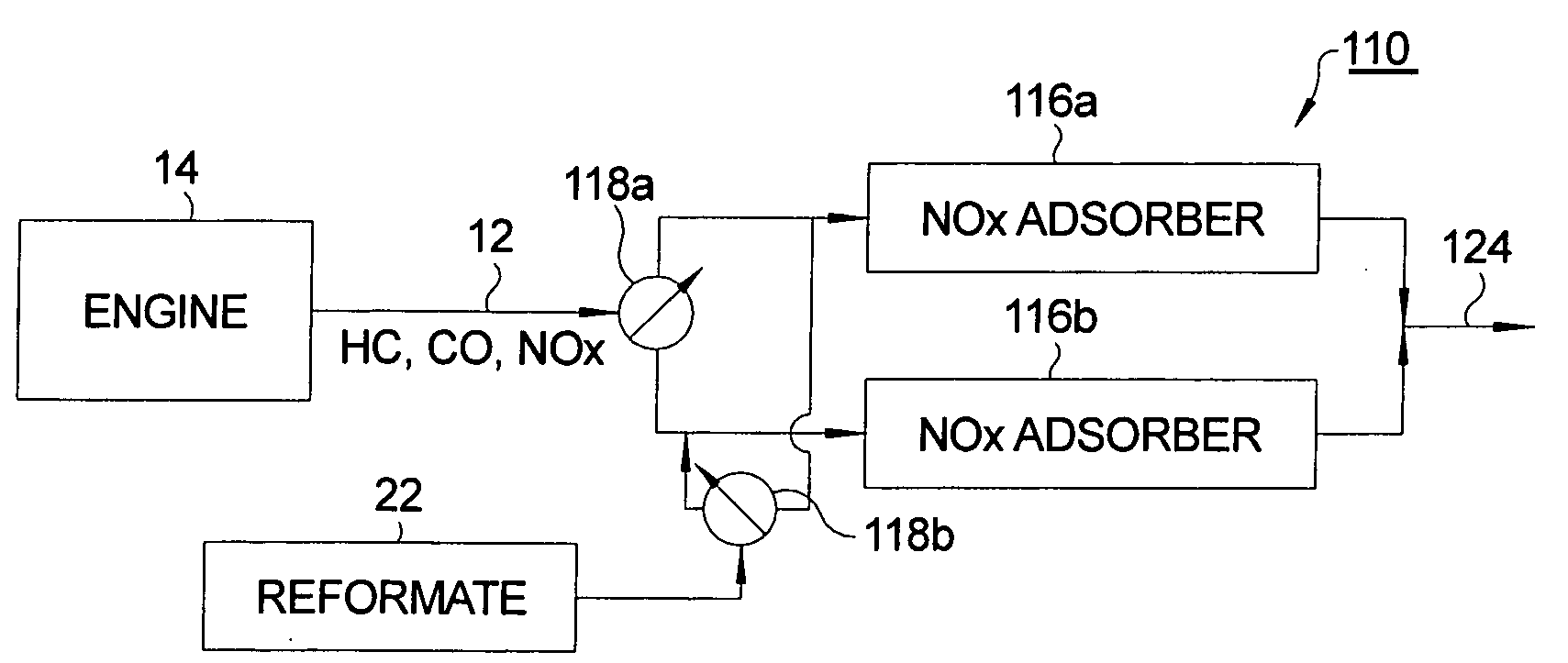

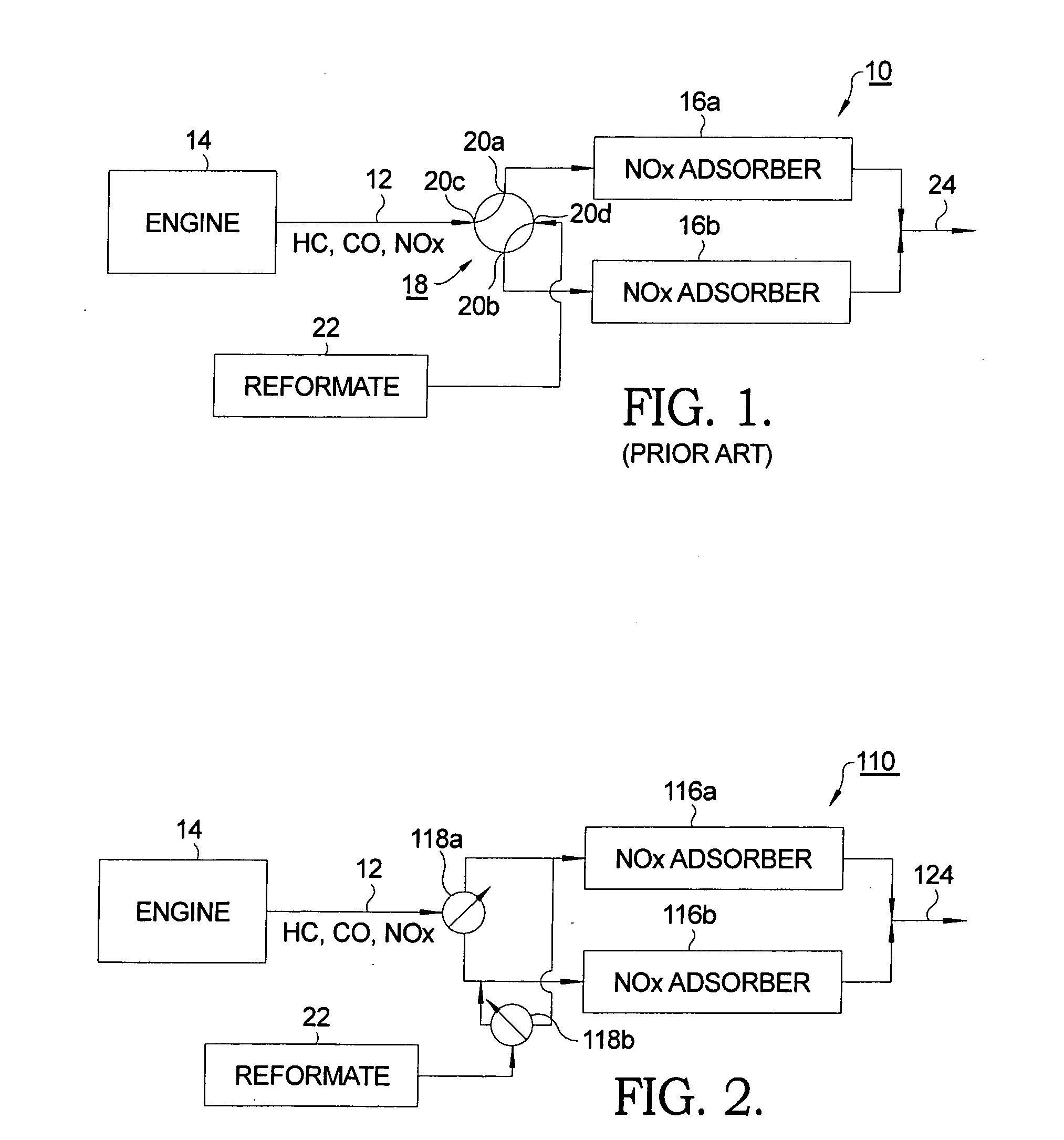

[0019]Referring to FIG. 1, a prior art dual trap emissions adsorber system 10 for controlling exhaust emissions 12 from an internal combustion engine 14 comprises a first catalytic NOx trap 16a and a second catalytic NOx trap 16b supplied with exhaust emissions 12 via a four-port valve 18. Traps 16a,16b are connected to first and second opposite ports 20a,20b of valve 18, respectively, and engine 14 and reductant 22 are connected to third and fourth opposite ports 20c,20d, respectively. As shown in FIG. 1, valve 18 is positioned to deliver emissions through first trap 16a for storage of NOx to yield a cleaned exhaust 24, and reductant 22 through second trap 16b simultaneously for regeneration thereof. Typically, reductant 22 is hydrocarbon reformate supplied from a source, not shown. When the valve core is rotated 90° in either direction, it will be seen that emissions 12 now flow to second trap 16b for NOx storage to yield cleaned exhaust 24, and reformate 22 flows to first trap 16a f

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap