PDC drill bit capable of achieving casing drilling and design method thereof

A casing drilling and design method technology, applied in the direction of drill bits, drilling equipment, earthwork drilling and production, etc., can solve the problems of low drilling plug efficiency, downhole safety risks, complexity, etc., and achieve the effect of avoiding casing cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

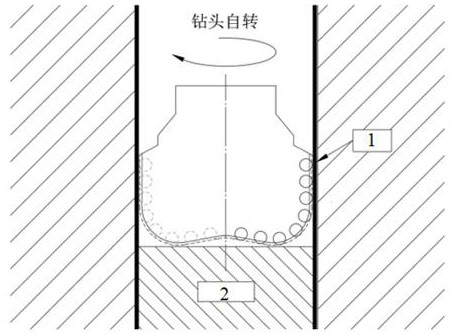

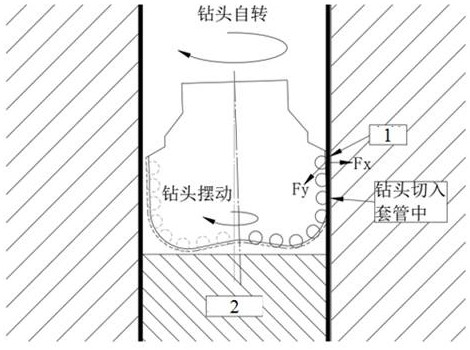

[0044]In order to solve the problems existing in the traditional PDC drill bit when drilling into the cement section 2 in the casing, a design method for a PDC drill bit capable of casing drilling is specifically provided in this embodiment. The technical principle of the design method is: adopt 6 points The isolation method isolates the PDC drill bit from the casing 1 to prevent the cutting teeth 6 on the drill bit from cutting the casing during drilling. Take the 6-point isolation method as an example, such as Figure 5 As shown, the design method includes:

[0045] Install and arrange 6 isolation units 5 on the blade gauge part 4 of the PDC drill bit, and each isolation unit 5 is made of hard alloy. surface 8, and it can ensure that the continuation of drilling efficiency after drilling out of the casing 1 is not affected), but in actual application, it is not limited to only arranging six isolation units 5. It should be noted that: if the number of isolation units 5 If ther

Embodiment 2

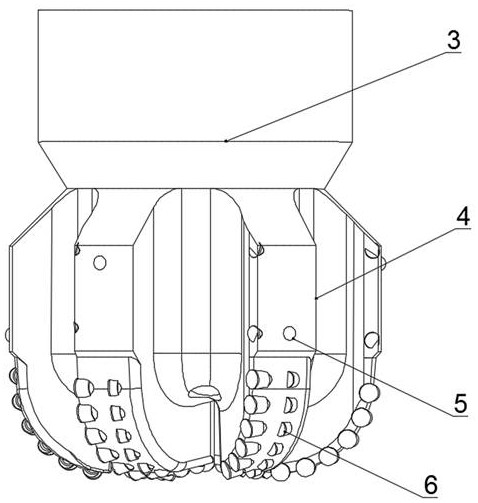

[0057] In Embodiment 1, a design method of a PDC drill bit capable of casing drilling is provided, and a corresponding PDC drill bit is designed according to the design method provided. Drilling PDC bits such as image 3 , Figure 4 As shown, it includes a drill body 3, a plurality of blades evenly distributed on the drill body 3 along the same circumferential direction, and each blade is divided into a gage part and a cutting tooth part 6, and the PDC drill bit also includes:

[0058] Two isolation unit groups, each isolation unit group is provided with 3 isolation units 5 (there are 6 isolation units 5 in total in the two isolation unit groups), each isolation unit 5 is made of hard alloy, and the same isolation unit Each isolation unit 5 of the group is respectively arranged on the gage part of each described blade and is surrounded by each isolation unit 5 of this isolation unit group to form a virtual plane 7; In the present embodiment, each isolation unit group respectivel

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap