Stamping part surface grinding device for refrigerator production

A technology for stamping parts and refrigerators, which is applied in the field of surface grinding devices for stamping parts used in refrigerator production. It can solve the problems of easily injuring workers, affecting work efficiency, increasing work intensity, etc., and achieves the effects of improving grinding efficiency, convenient operation, and avoiding accidental injuries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to clearly understand the technical solution of the present invention, its detailed structure will be presented in the following description. It is apparent that the implementation of the embodiments of the invention is not limited to specific details familiar to those skilled in the art. The preferred embodiments of the present invention are described in detail below, and there may be other implementations besides those described in detail.

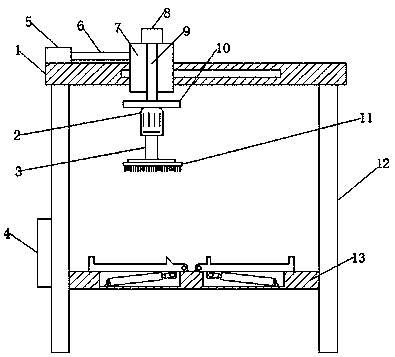

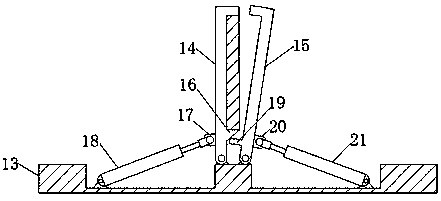

[0018] As shown in the figure, a surface grinding device for stamping parts used in refrigerator production according to the present invention includes a crossbeam 1, a chute is arranged inside the crossbeam 1, and a slider 7 is installed on the outside of the crossbeam 1, and the slider 7 is slidably connected with the chute, a first drive cylinder 5 is installed on one side of the upper surface of the crossbeam 1, and a first telescopic rod 6 is installed on the output end of the first drive cylinder 5, and the other end o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap