Dephosphorization wheel shaft

A wheel shaft and bearing seat technology, applied in the direction of grinding machines, grinding machine parts, metal processing equipment, etc., can solve the problems of easily damaged and dephosphorized wheel shaft precious parts, troublesome disassembly and maintenance, time-consuming and labor-intensive problems, and achieve easy maintenance and maintenance , Simple and compact structure, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

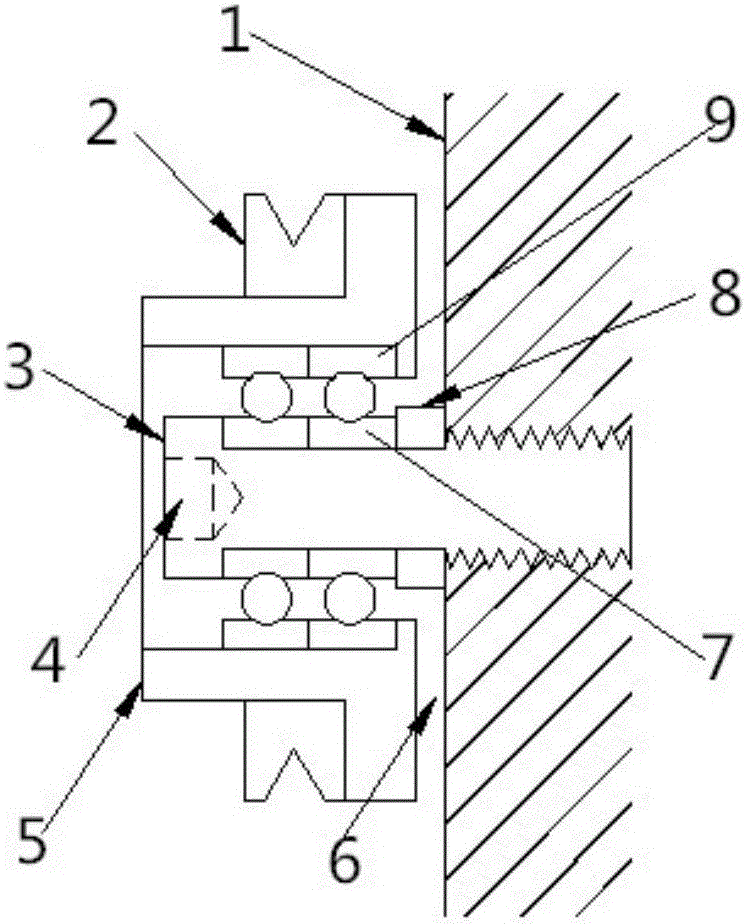

[0015] Such as figure 1 As shown, the phosphorus removal wheel shaft includes a base 1, an alloy ring 2, a phosphorus removal shaft 3, an inner hexagon thread 4, a bearing seat 5, a gap 6, an inner steel ring 7, a spacer ring 8 and an outer steel ring 9.

[0016] One end of the dephosphorization shaft 3 is threaded and installed on the base 1 , and the other end of the dephosphorization shaft 3 is provided with an inner hexagon thread 4 . An inner steel ring 7 and an outer steel ring 9 are sequentially arranged on the outer periphery of the phosphorus removal shaft 3 . A bearing seat 5 is arranged on the outer side of the outer steel ring 9, and an alloy ring 3 is arranged on the bearing seat 5. A gap 6 is reserved between the dephosphorization shaft 3 and the base 1 , and a spacer 8 is provided between the inner steel ring 7 on the dephosphoriz

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap