Multifunctional through sleeve

A penetrating sleeve, multi-functional technology, applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problems of reducing equipment assembly efficiency, unable to assemble the screwdriver head, etc., to achieve the effect of fast switching, meeting assembly requirements, and reducing assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] The following examples are for illustrative purposes only, and are not intended to limit the scope of the present invention.

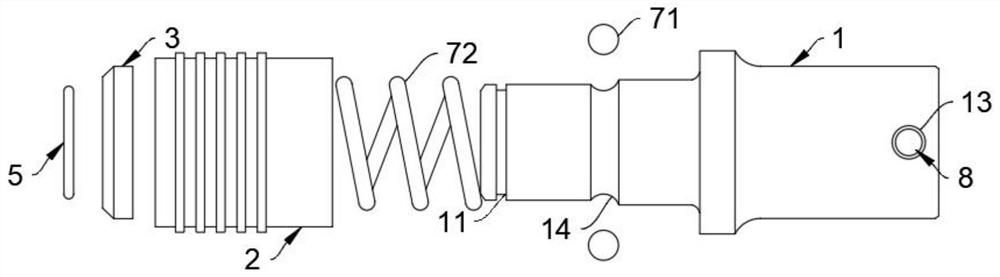

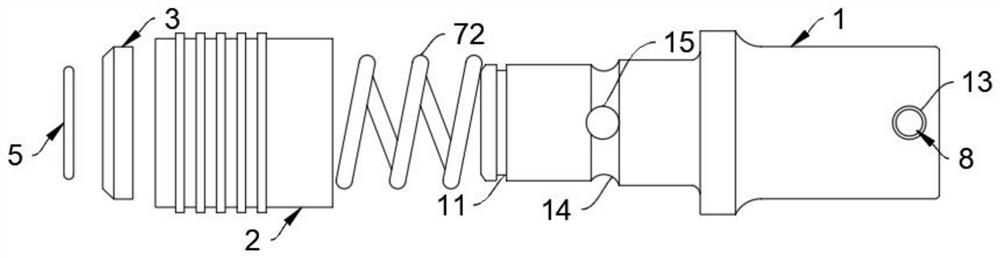

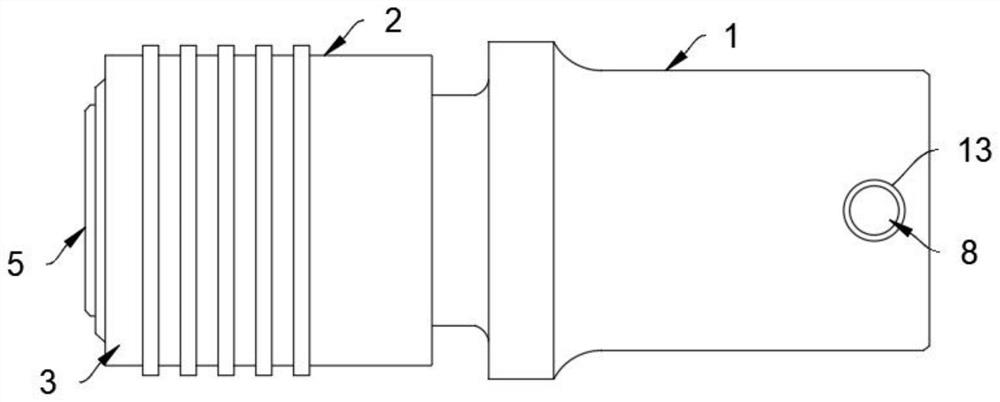

[0028] Such as Figure 1-7 As shown, a multifunctional core-through sleeve includes a sleeve body 1 and a rotating sleeve 2. The sleeve body 1 is detachably connected by a connecting block 3 and a rotating sleeve 2, and the connecting block 3 and the rotating sleeve 2 are threadedly connected. The inside of the rotating sleeve 2 is provided with a step 21, the connecting block 3 is provided with an external thread, and the external thread of the connecting block 3 is threaded with the step 21 to facilitate the installation of the connecting block 3, and the outer side of the rotating sleeve 2 is provided with anti-skid patterns , It is convenient for the rotation adjustment of the rotating sleeve 2.

[0029] One end of the connecting block 3 is rotatably connected to the sleeve body 1 through the limiting member 4. It should be noted that the limiting

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap