Lamp core of LED light bar lamp and manufacturing method of lamp core

A technology for LED light bars and light bar lights, which is applied in the manufacture of printed circuits, lighting and heating equipment, and components of lighting devices, etc., can solve the problems of low welding efficiency, high production costs, and inconvenient assembly of lamp wicks. Low cost, high assembly efficiency, easy automatic welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

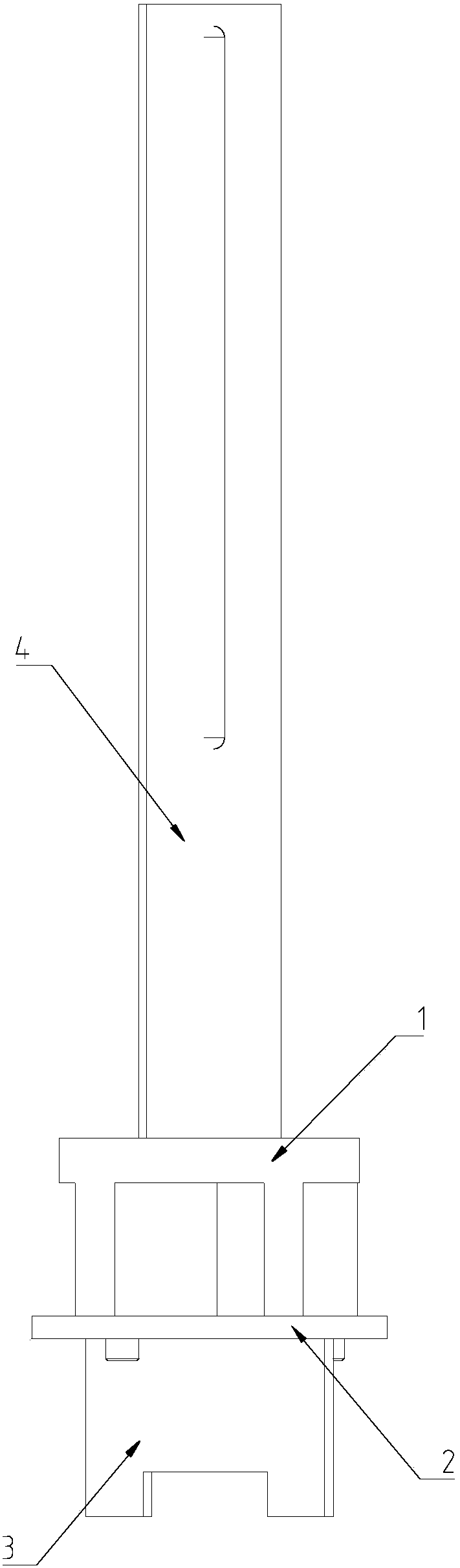

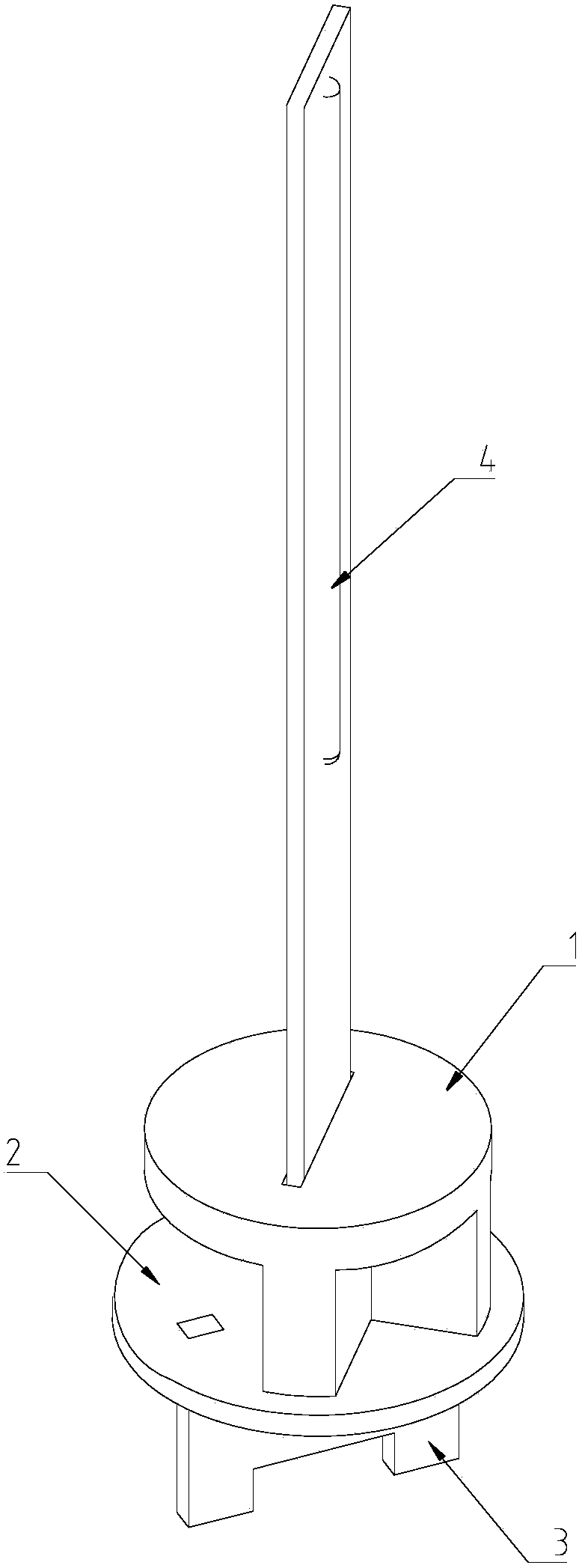

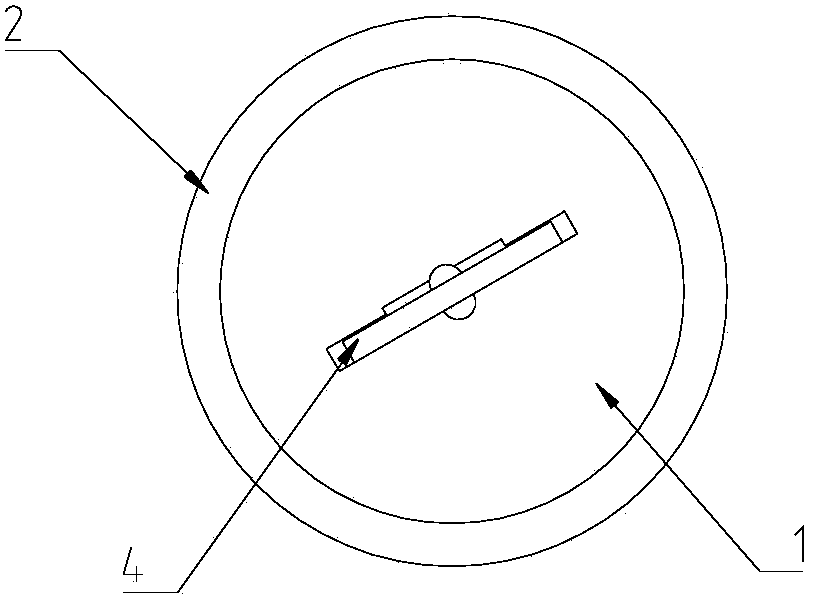

[0045] The structure of the wick of embodiment 1 of the present invention is as follows Figure 1 to Figure 11 As shown, it includes a bracket 1, a circuit connection board 2, a power supply board 3 and an LED light bar 4.

[0046] The LED light bar 4 is a double-sided light bar, including a glass substrate 401, an LED light string 402 arranged on both sides of the glass substrate 401, and two pads 403 arranged at the lower end of the glass substrate 401. The pads 403 pass through a printed circuit on the substrate 401 It is electrically connected to the LED light string 402.

[0047] The support 1 includes a plate body 101 and two vertical plates 102. The top end of the vertical plate 102 is connected to the bottom surface of the plate body 101, and the two vertical plates 102 are connected to each other. There is an elongated through hole 103 in the middle of the disc body 101, and two vertical plates 102 avoid the through hole 103. The vertical plate 102 arranged in the middle has

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap