Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Staying time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Parallel-flow low-lying condenser

InactiveCN103471415AImprove mixing efficiencySimple structureSteam/vapor condensersEngineeringWater spray

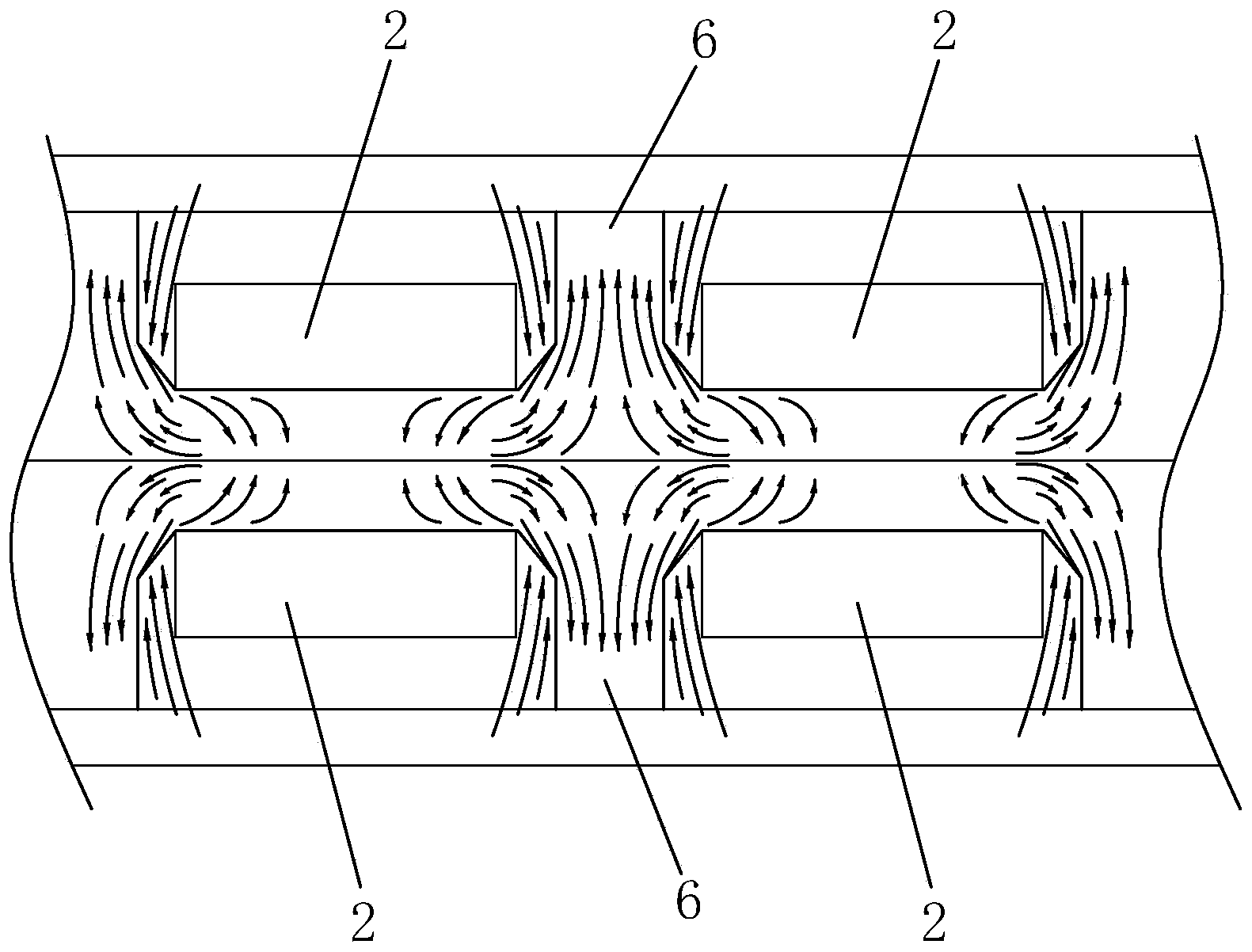

The invention relates to a parallel-flow low-lying condenser, which comprises a shell. A steam inlet pipe is arranged at the upper end of the shell. A condensate outlet pipe is arranged at the lower end of the shell. A sprayer is arranged at the steam inlet of the steam inlet pipe. Deflectors are arranged on the inner wall of the shell. One side of each deflector is fixedly arranged on the inner wall and the other side of each deflector is provided with a baffle which is upwards perpendicular to the deflector. The lower end of the sprayer is connected with a water inlet pipe which penetrates through the wall of the shell. The water spraying side of the sprayer is upwards arranged. The parallel-flow low-lying condenser has the advantages that the staying time of cooling water in the condenser can be prolonged to enable steam to be in full contact with the cooling water and the mixing ratio is improved.

Owner:王毓芳

Drying oven for lithium battery coating machine and drying oven air current control method

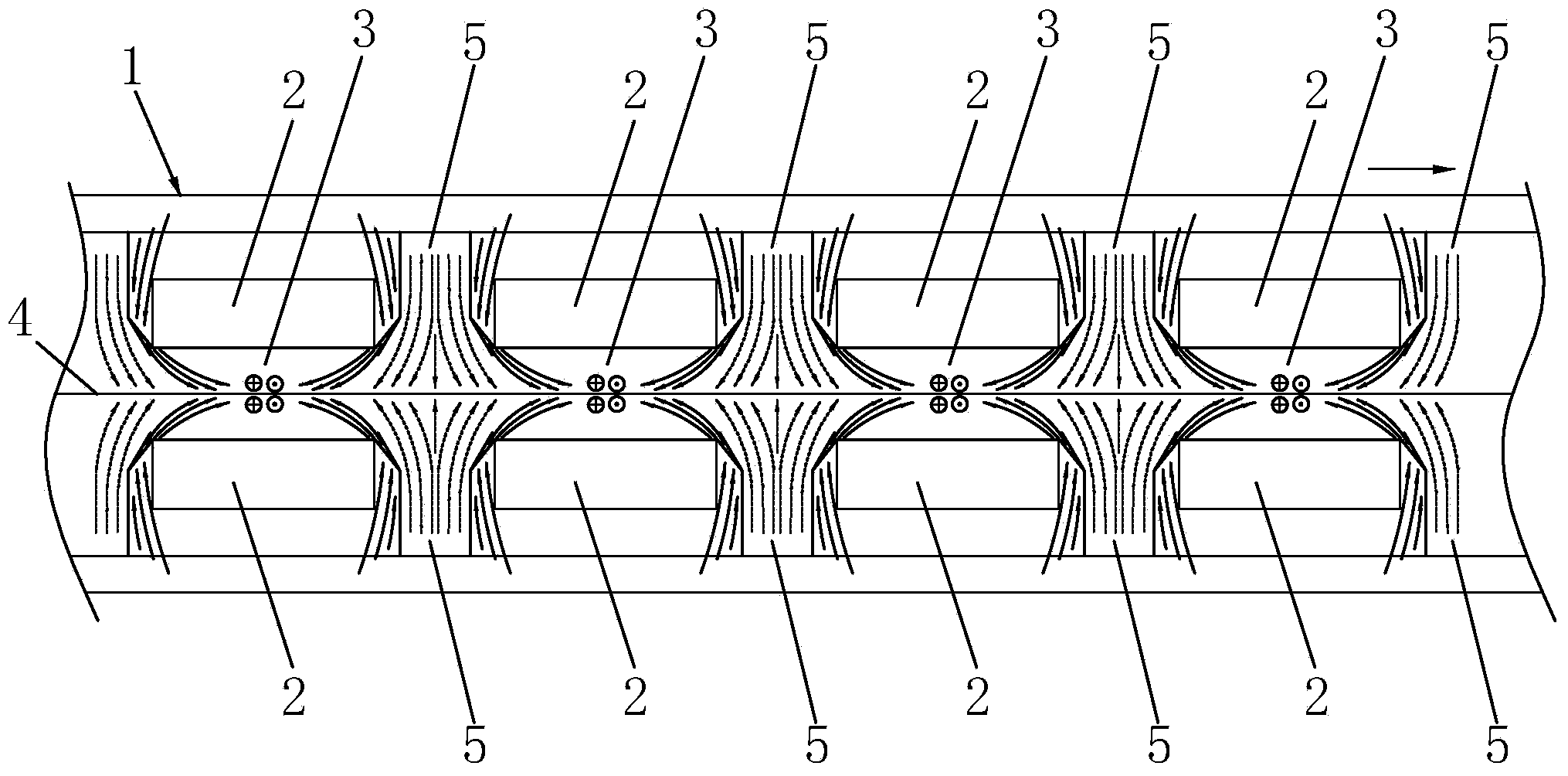

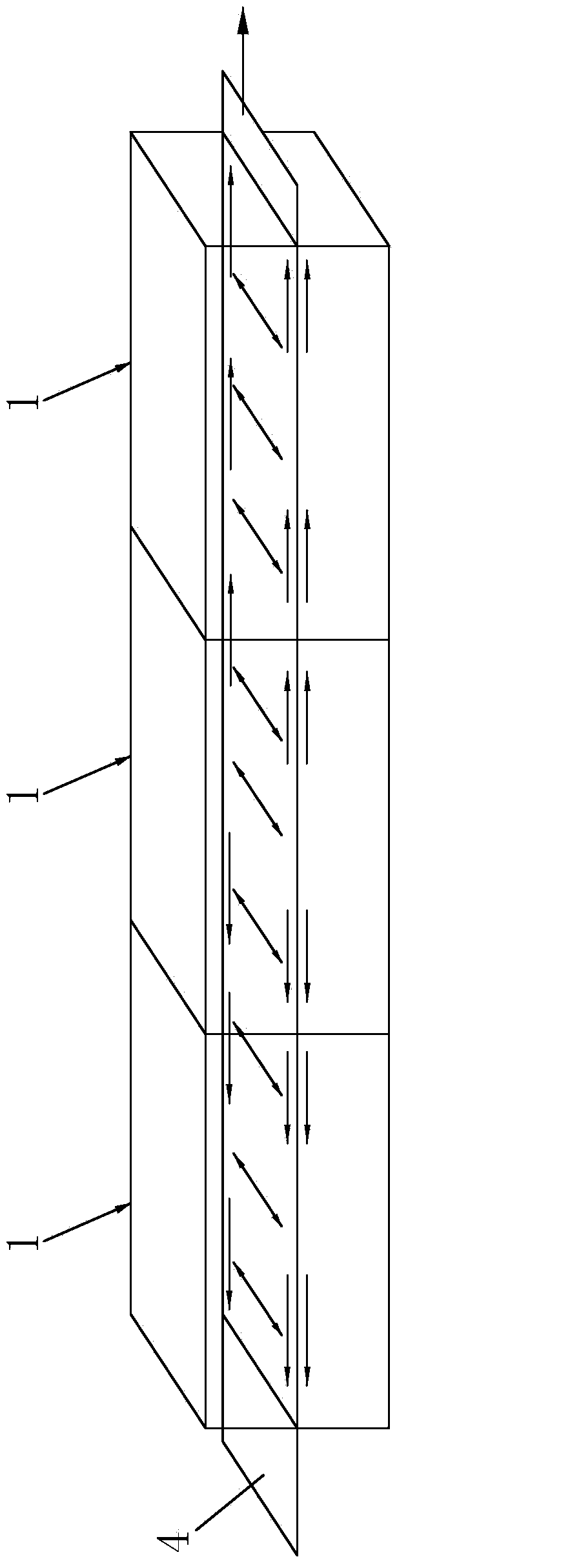

The invention discloses a drying oven for a lithium battery coating machine and a drying oven air current control method. The method includes: a negative-pressure air suction area is formed between each two adjacent air nozzles after air nozzles blow hot air to the surface of a material strap; the negative-pressure air suction area between each two adjacent air nozzles supplies air or hot air to the surface of the material strap; hot air gathered in a middle high-pressure area flows to low-pressure areas on two sides; hot air on the upper and lower surfaces of the material strap flows along the forward direction of the material strap or flows in a direction opposite to the forward direction of the material strap. Air current in the drying oven is controlled stably, air whirl is avoided, the hot air is discharged stably, staying time of the hot air in the drying oven is long, and consequently hot air utilization rate is increased, less energy is consumed for drying the material strap, effectiveness in material strap heating is achieved, and drying quality and drying efficiency are improved.

Owner:广东海中新能源设备股份有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap