Water heater water tank and air energy water heater

A water heater water tank and water tank technology, which is applied to fluid heaters, lighting and heating equipment, etc., can solve the problems of low heat exchange efficiency of the condenser and high system pressure, and achieve the effect of high heat exchange efficiency and improved heat exchange performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

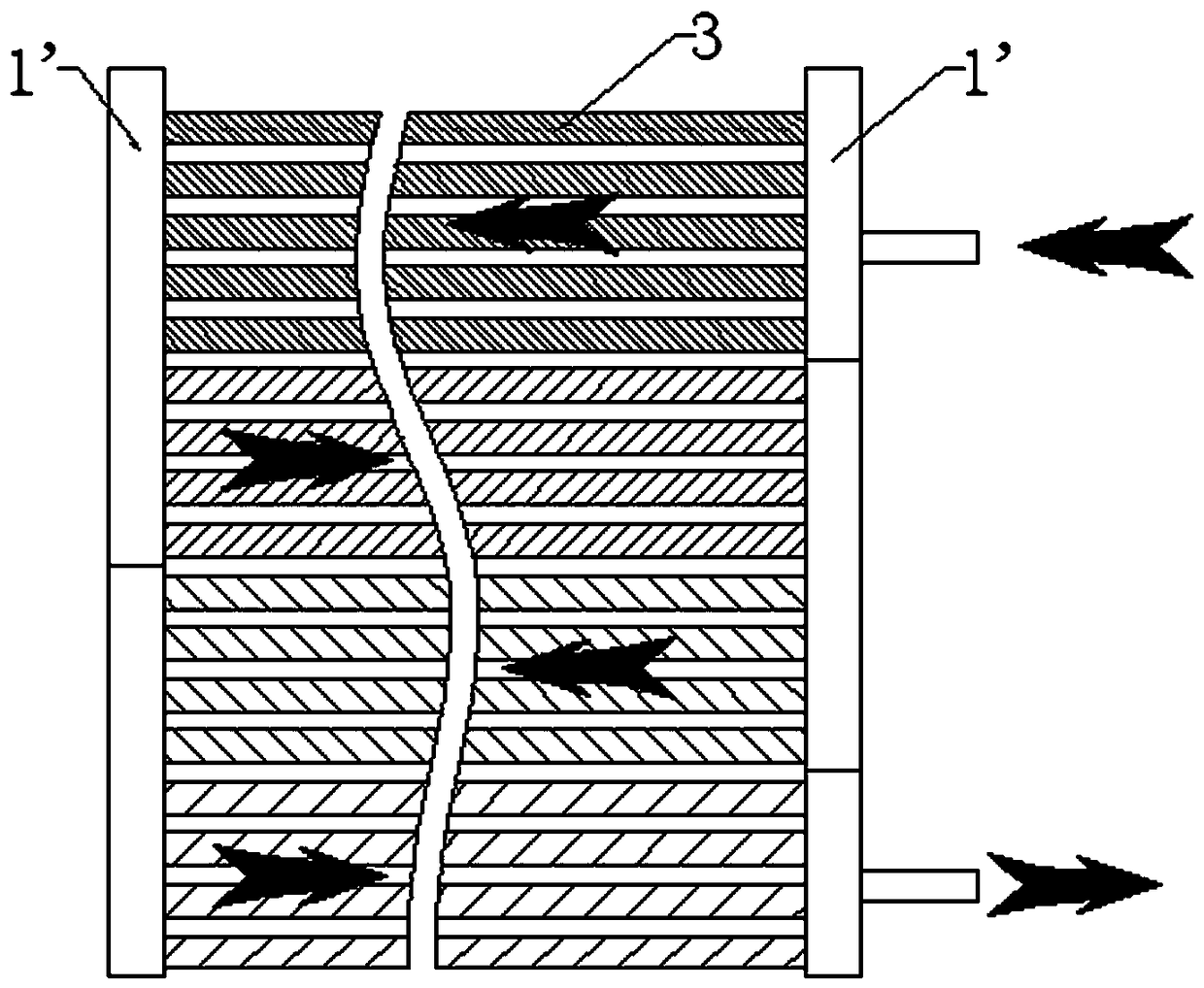

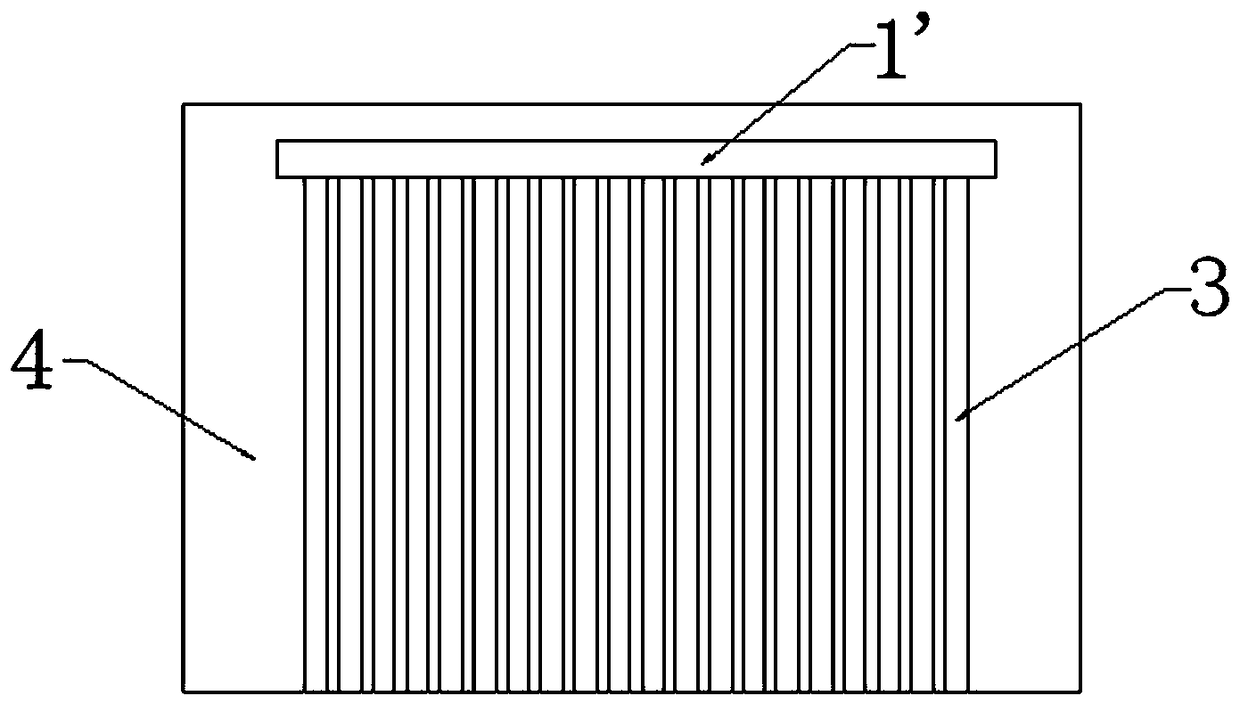

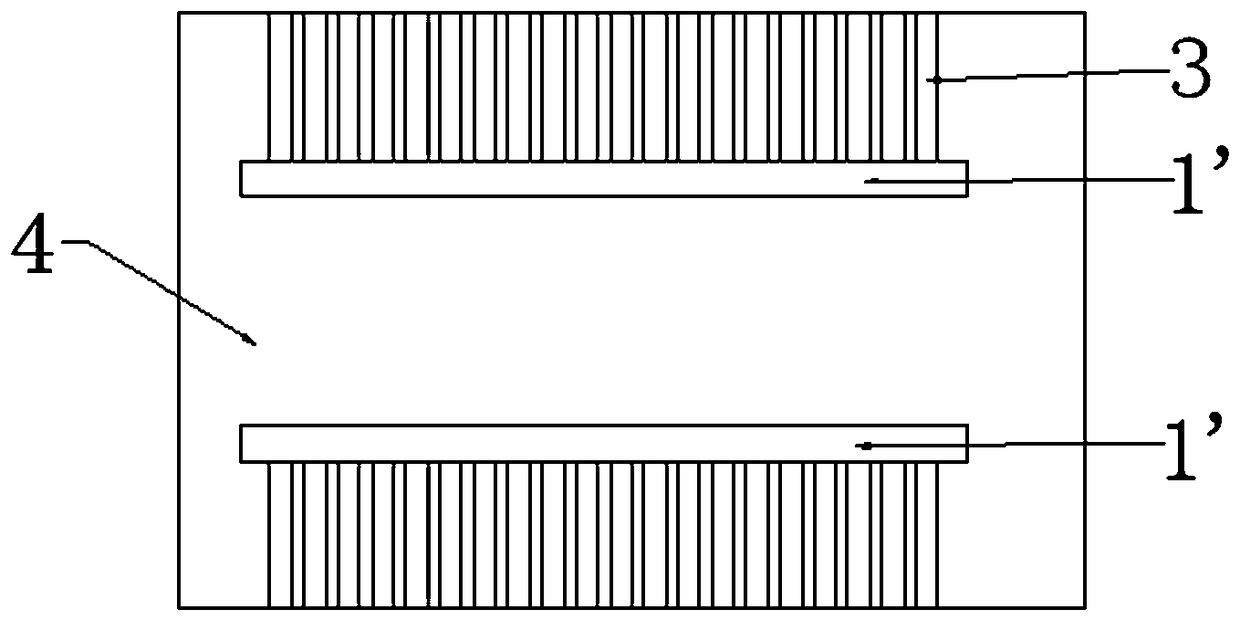

[0031] Such as Figure 5 As shown, the water heater water tank proposed by the present invention includes a water tank liner 4, and at least one side of the water tank liner 4 is covered with a heat exchanger. In actual use, it can be selected on one side or both sides or even according to the specific shape of the water tank liner. More sides wrap the heat exchanger.

[0032] The heat exchanger includes: a first header 1, a second header 2 and a heat exchange tube group. The heat exchange tube group consists of several tubes arranged at intervals between the first header 1 and the second header 2 The heat exchange tube 3 is formed, one end of the heat exchange tube 3 is connected to the first header 1 , and the other end of the heat exchange tube 3 is connected to the second header 2 .

[0033] The inside of the first header 1 is hollow, and the inside of the second header 2 is also hollow. The first header 1 is provided with a refrigerant inlet 11, and the second header 1 is p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap