Apparatus and method for treating electroplating plant area sewage

A sewage treatment device and plant area technology, applied in the direction of water/sewage treatment, water/sewage treatment equipment, water/sewage multi-stage treatment, etc., can solve the problem that the sewage treatment method cannot meet the sewage discharge standard, and achieve easy disassembly and replacement, reasonable structural design and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

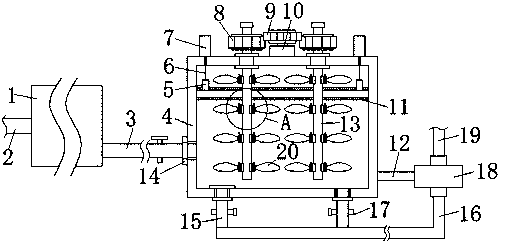

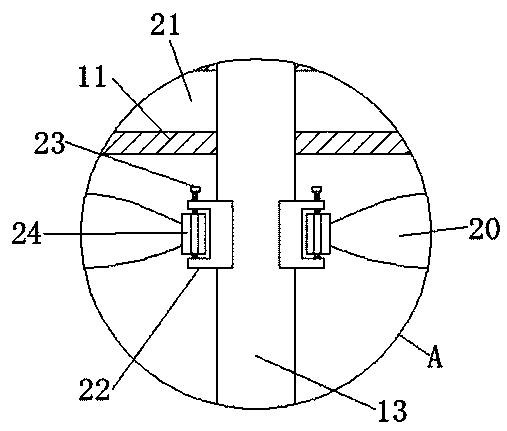

[0016] refer to Figure 1-2 , the electroplating plant sewage treatment device, including a sedimentation tank 1, the sedimentation tank 1 is provided with a sedimentation chamber, the side wall of the sedimentation tank 1 is provided with a first connecting pipe 2 communicating with the sedimentation chamber, and the sedimentation tank 1 is far away from the first connection The side wall at one end of the pipe 2 is penetrated with a second connecting pipe 3 communicating with the sedimentation chamber, and the side wall at one end of the second connecting pipe 3 far away from the sedimentation tank 1 is connected with a stirring tank 4, and the inside of the stirring t

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap