Wireless liquid level automatic control system of single point liquid level detection

A liquid level detector, liquid level technology, applied in liquid level control, control/regulation system, non-electric variable control, etc. The effect of saving installation cost, prolonging use time and ensuring equipment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

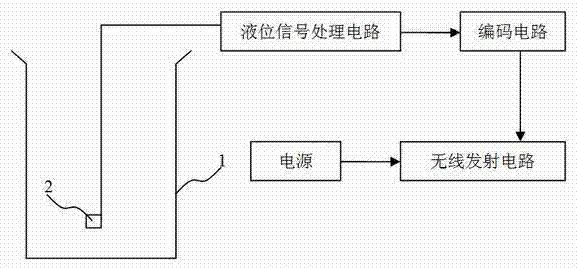

[0016] Fully automatic drainage control: The user first adjusts the timing of the controller to make it consistent with the single normal drainage time based on the volume of the fluid container and the drainage speed of the drainage equipment. When in the fully automatic drainage state, the liquid level detection sensor 2 is placed at the set upper limit position of the fluid container 1. When the fluid is submerged to the liquid level detection sensor 2, the liquid level signal processing circuit processes the liquid level information to eliminate interference Information, when it is determined to be full of water information, start the encoding circuit to send the start-up encoding information, and send it to the air through the radio transmission circuit, and then start the delay detection function of the liquid level state, within the set time, if the liquid level detection sensor is still In the state of being submerged by fluid, it is considered that the drainage device has

Embodiment 2

[0018] Fully automatic water supply control: The user firstly adjusts the timing of the controller to make it consistent with the single normal water supply time based on the volume of the fluid container and the water supply speed of the water supply equipment. When in the fully automatic water supply state, the liquid level detection sensor 2 is placed at the lower limit position of the fluid container 1. When the fluid drops below the liquid level detection sensor 2, the liquid level signal processing circuit processes the liquid level information to eliminate Interference information, when it is determined to be water shortage information, start the coding circuit to send the power-on coding information, and send it to the air through the radio transmission circuit, and then start the delay detection function of the liquid level state, within the set time, if the liquid level detection sensor Still in the state of water shortage, it is considered that the water supply equipmen

Embodiment 3

[0020] Manual button control: The user sets the timing time, and then operates the button to trigger the timing circuit to work, and the water supply and drainage equipment will supply and drain water within the set time range. When the timing time ends, the equipment will automatically stop. If it is necessary to forcibly control the shutdown of the device, the forced shutdown is performed by adjusting the timing time to 0.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap