Circular end cover edge spinning device

A technology with a round end and a lifting device, which is applied to other household appliances, household appliances, applications, etc., to ensure the quality of processing, improve processing efficiency, and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

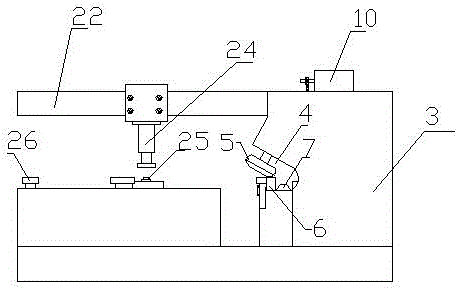

[0019] The circular end cap hemming device provided by the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

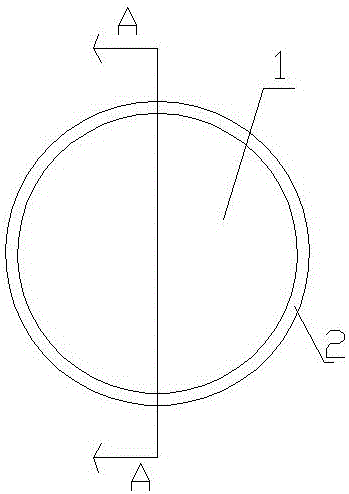

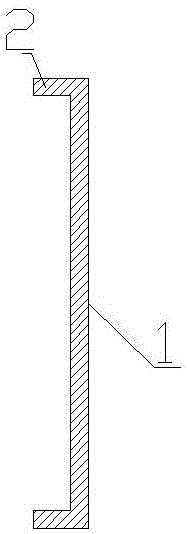

[0020] as attached image 3 As shown, a circular end cap hemming device includes a frame 3, and the frame is provided with a material-containing port 4, and also includes a driving pressure head 5, a pressing wheel 6 and a bending pressure head 7.

[0021] as attached Figure 6 As shown, the driving ram 5 is installed on the end of the driving shaft 8, and the driving shaft 8 is located in the frame above the material-containing mouth and fixed by bearings. The driving shaft 8 is arranged obliquely, and the angle between the driving shaft and the vertical line is 45°, the driving head 5 is located above the inside of the material-containing port.

[0022] as attached Figure 5 As shown, the front end side of the driving ram 5 is provided with a profile surface 9 inclined to the top, and the angle between

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap