Multi-shouldered fixed bobbin tools for simultaneous friction stir welding of multiple parallel walls between parts

a technology of friction stir welding and fixed bobbins, which is applied in the direction of manufacturing tools, welding devices, soldering devices, etc., can solve the problems of inability to use fsw tools similar to fsw tools, and inability to access the back side,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0168] The present invention teaches the concept of multi-shouldered fixed bobbin tools that afford simultaneous friction stir welding of multiple parallel walls between parts. The term “wall” here can mean a sheet, a plate, a flange or web, a planar portion of an extrusion or rolled product, or a planar portion of a casting, etc.

[0169] In the discussion which follows, directional terms such as “top”, “bottom”, “upper”, “lower”, etc are for reference only. The tools described are for use in any orientation.

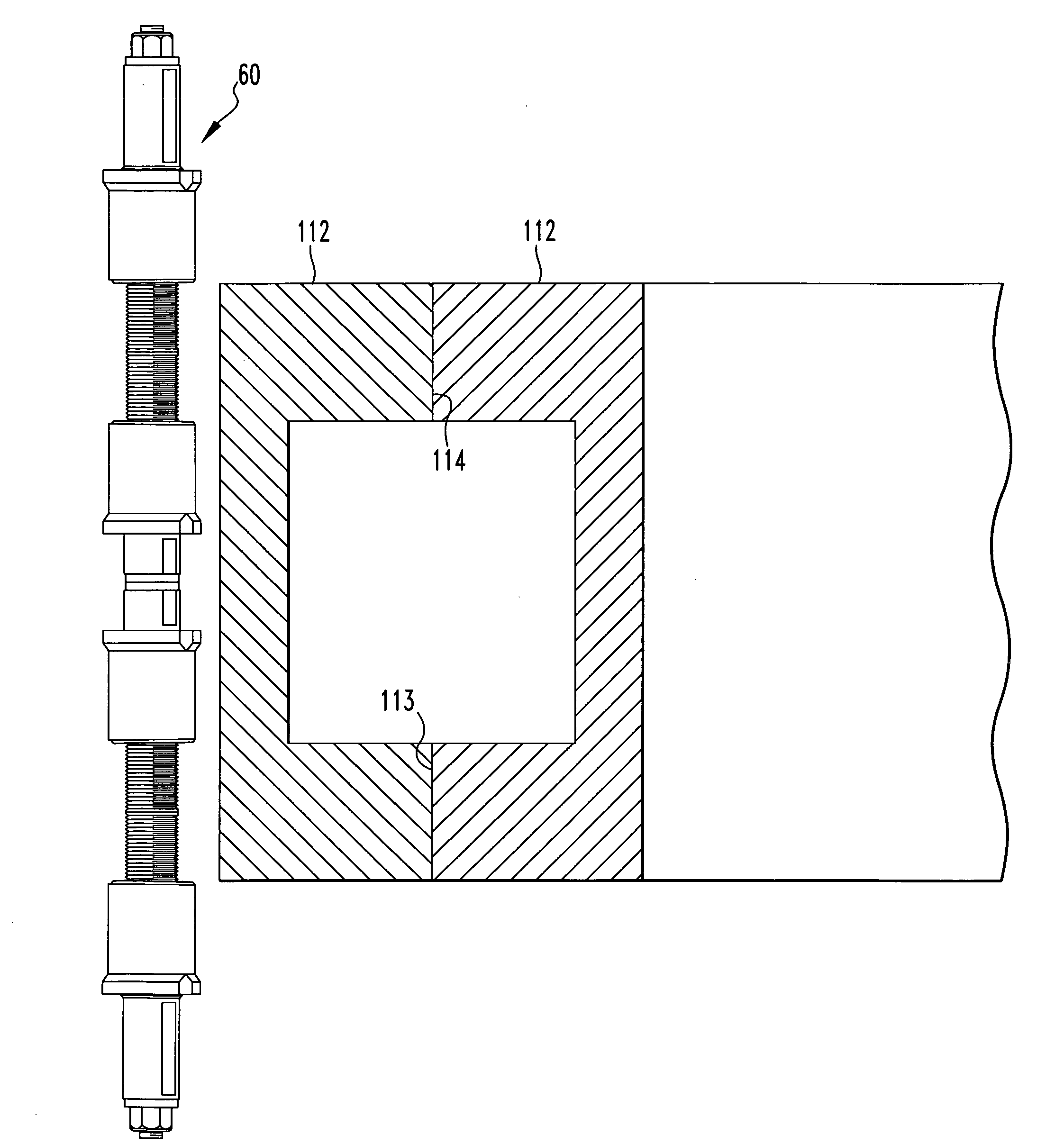

[0170]FIG. 8 illustrates a multi-shouldered fixed bobbin tool 60, according to the present invention. Bobbin tool 60 is for making two parallel welds simultaneously.

[0171] The inventors have realized that in order to FS weld with a multi-shouldered fixed Bobbin tool: [0172] a) Multiple parallel walls (e.g. 2-4), [0173] b) Relatively thick walls (2.5 cm), and [0174] c) Tough / strong alloys (e.g. 7085), the tool must be extra strong to resist the severe bending and twisting at its

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Tension | aaaaa | aaaaa |

| Torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap