Metal packaging tin forming machining machine and machining method

A technology of forming processing and packaging cans, which is applied in the field of packaging cans processing, can solve the problems of punching position changes, work process interference, and waste of working time, so as to avoid replacement and improve processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

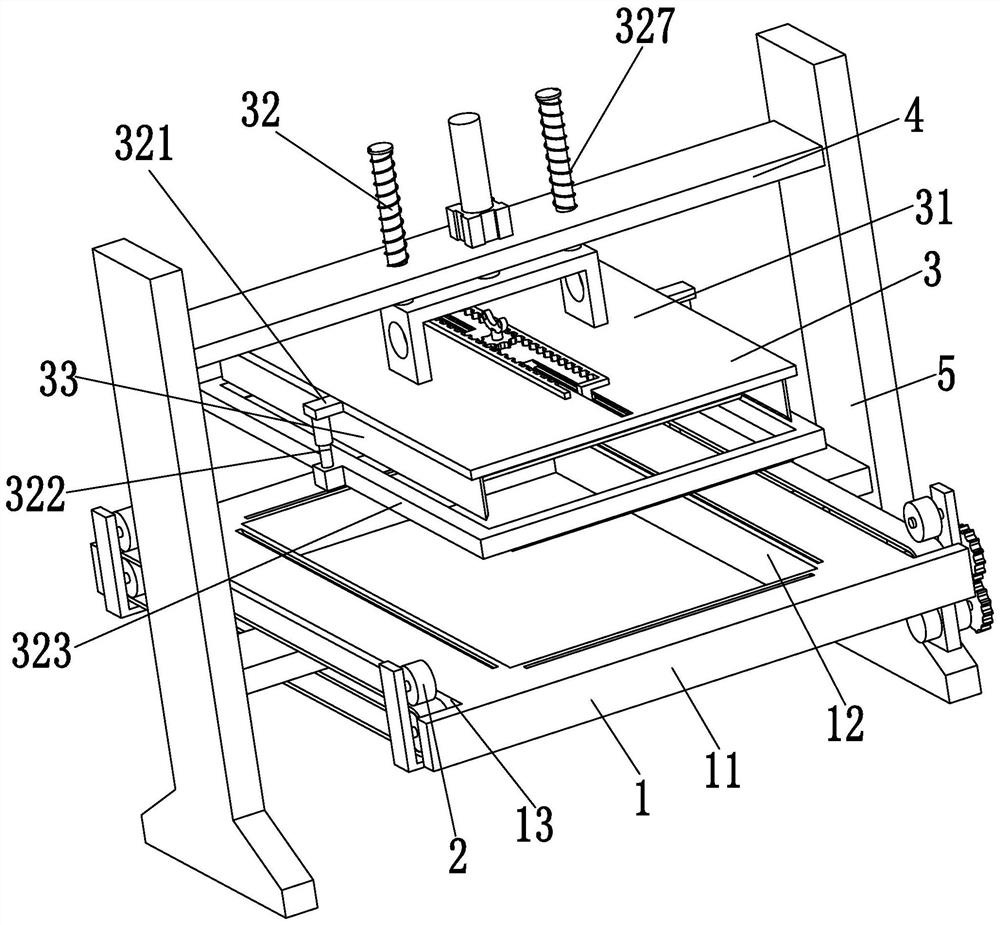

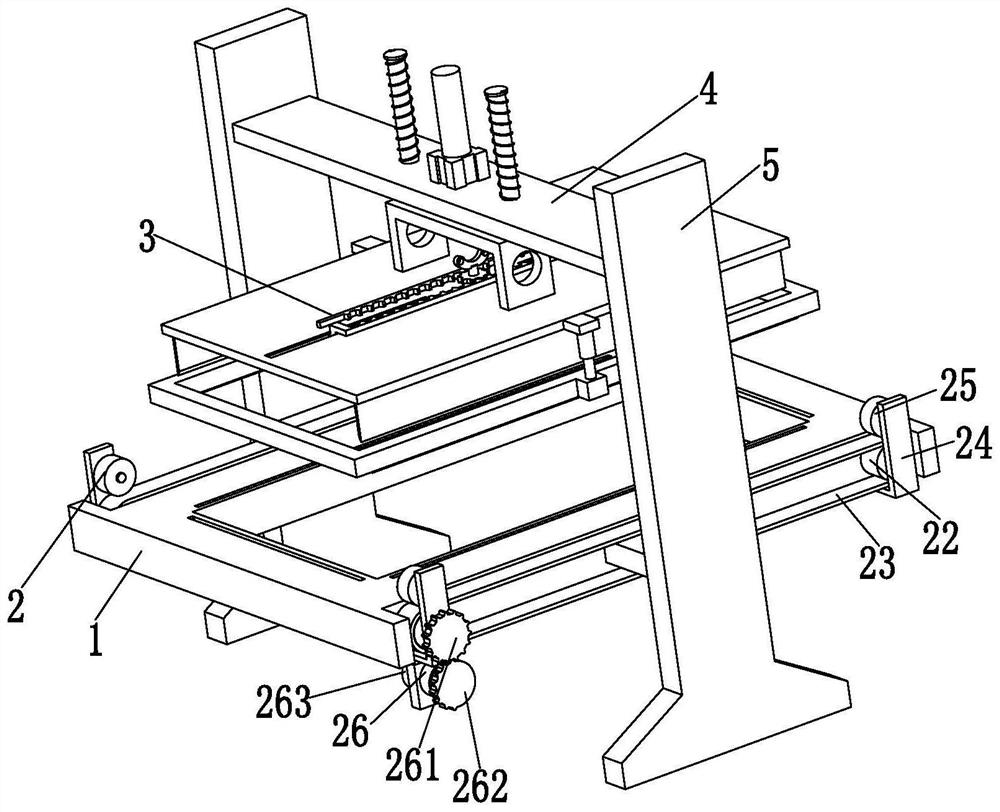

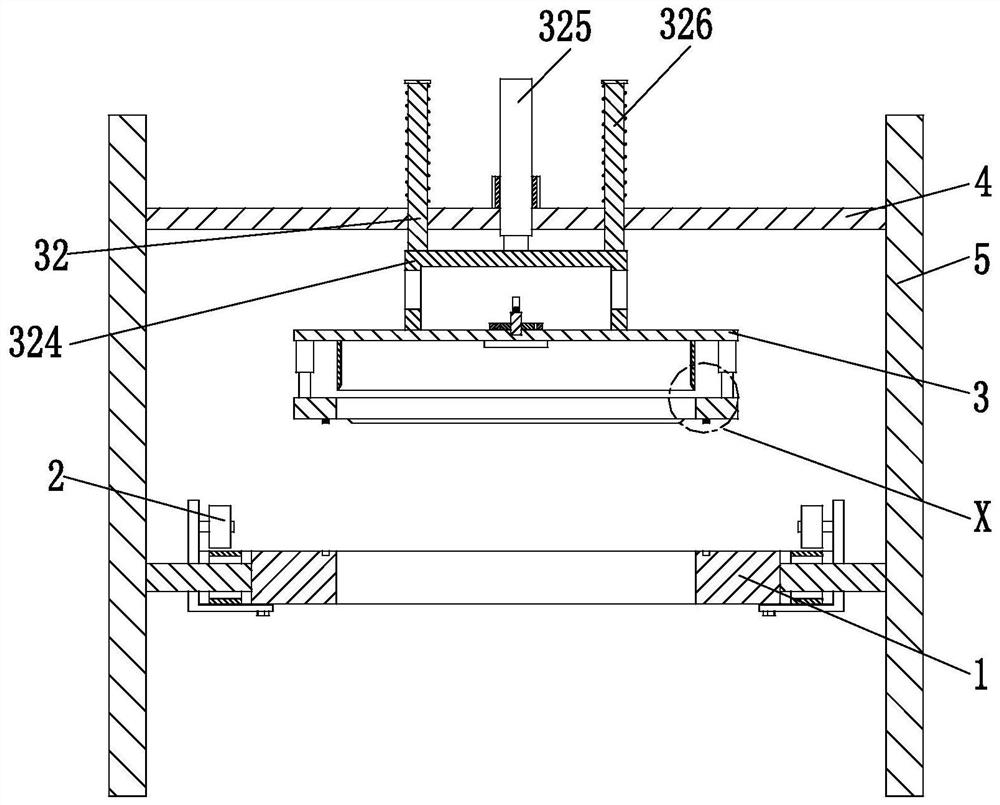

[0035] like Figure 1 to Figure 6 As shown, a metal packaging can molding processing machine includes a working base 1, an intermittent driving device 2, a punching device 3, a mounting plate 4, and a mounting base 5. The working base 1 is provided with an intermittent driving device 2, A punching device 3 is arranged above the intermittent driving device 2, and the punching device 3 is installed on a mounting plate 4, and the left and right ends of the mounting plate 4 are symmetrically connected with mounting bases 5.

[0036] The working base 1 comprises a working plate 11, a square discharge port 12 and a working groove 13, the middle part of the working plate 11 is provided with a square discharging port 12, and the left and right ends of the workin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap