Bottle body blowing machine capable of online detecting whether gas leakage exists in bottle body or not

A technology for blow molding machines and bottles, which can be applied to other household appliances, household appliances, applications, etc., and can solve the problems of inability to detect plastic bottle leaks online, weak structural strength, and easy leaks, etc., and achieve a fast inspection method Convenience, easy operation, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

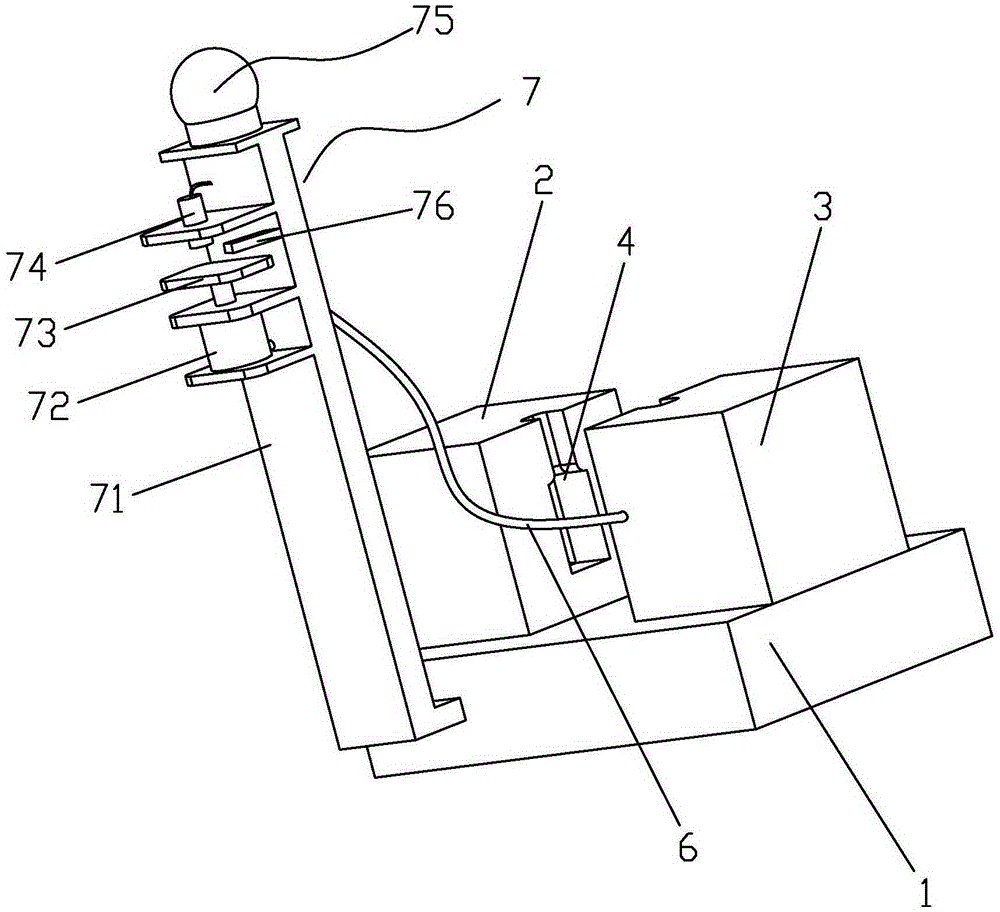

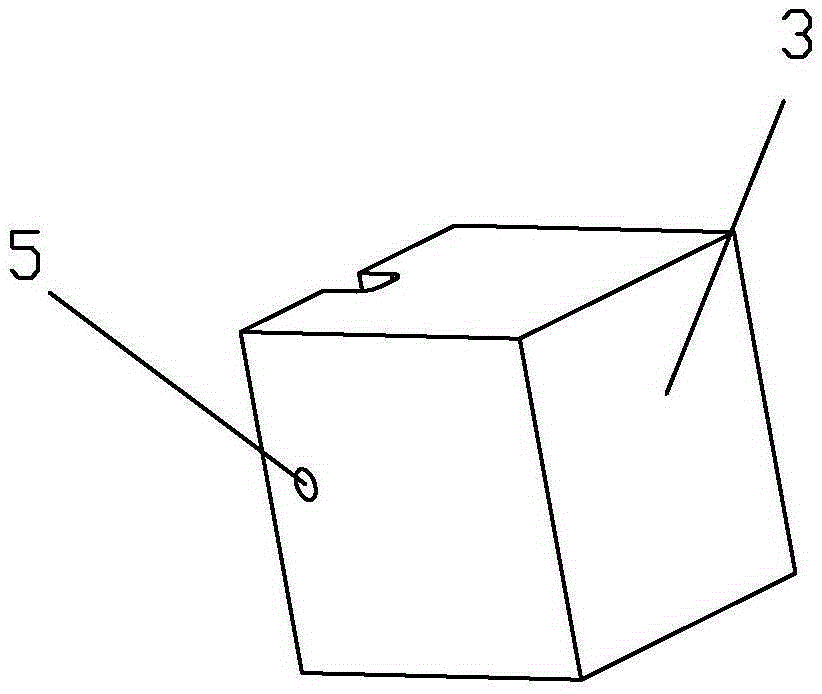

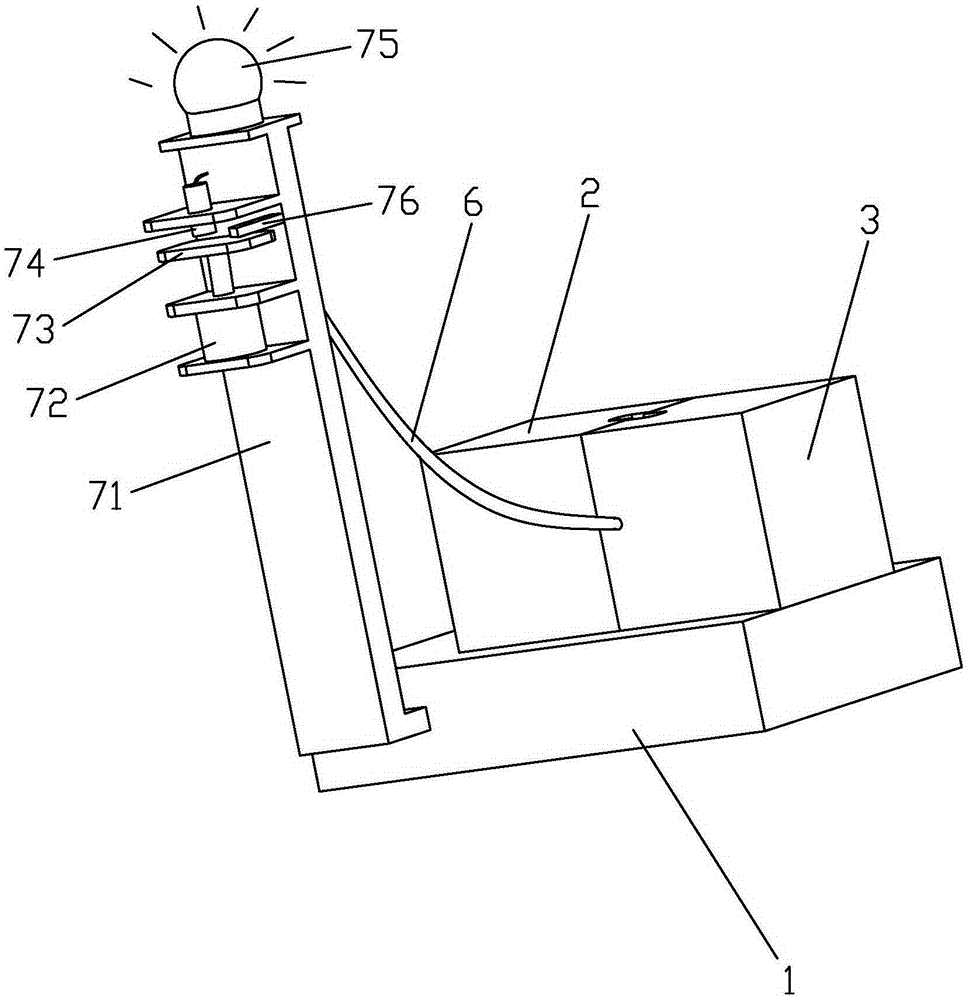

[0017] A bottle body blow molding machine capable of online detection of whether the bottle body is leaking air, comprising a machine 1 and a front mold 2 and a rear mold 3 arranged on the machine 1, and the front mold 2 and the rear mold 3 are provided with When the two are combined, it is used for the mold cavity 4 of bottle blow molding, and the bottle blow molding machine also includes an air leakage detection device for detecting whether the plastic bottle formed in the mold cavity 4 leaks. The air leakage detection device includes an air flow passage 5 connected to the mold cavity 4 on the front mold 2 or the rear mold 3, the air flow passage 5 is connected with a flexible air pipe 6, and the machine table 1 is provided with A gas inspection device 7 capable of detecting gas in the air pipe 6. The gas inspection device 7 includes a bracket 71 arranged on the machine plat

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap