Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Phosphogypsum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phosphogypsum refers to the calcium sulfate hydrate formed as a by-product of the production of fertilizer from phosphate rock. It is mainly composed of gypsum (CaSO₄·2H₂O). Although gypsum is a widely used material in the construction industry, phosphogypsum is usually not used, but is stored indefinitely because of its weak radioactivity. The long-range storage is controversial.

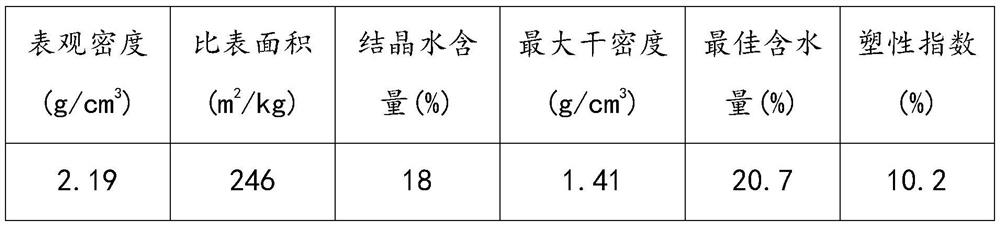

Modified phosphogypsum highway subgrade filler and preparation method thereof

Owner:WUHAN HUAZHONG UNIV OF SCI & TECH TESTING TECH CO LTD +1

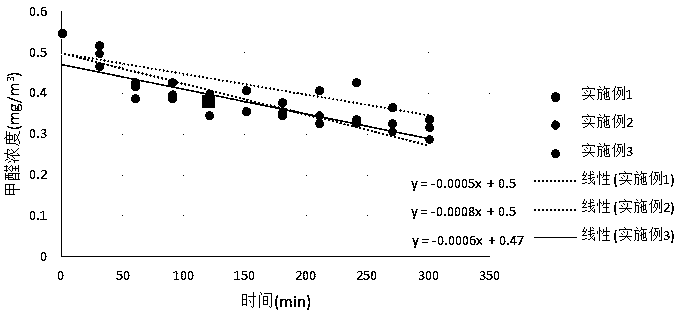

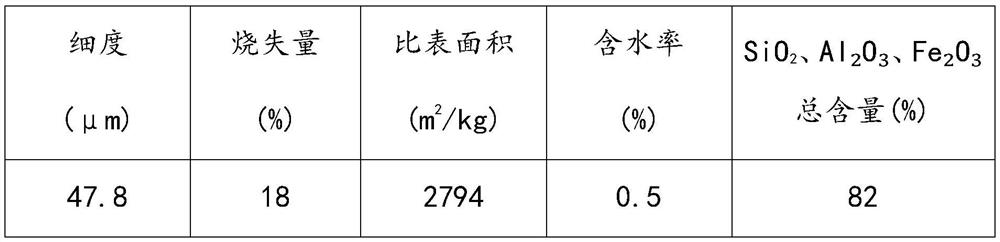

Photocatalytic concrete prepared with phosphogypsum-based hydraulic composite binding material and preparation method of photocatalytic concrete

Owner:TONGJI UNIV

Light sandwich paperless gypsum board containing high-temperature phosphogypsum as well as preparation method and application thereof

ActiveCN111268987ANot easy to moldLight weightLaminationLamination apparatusFiberglass meshGlass fiber

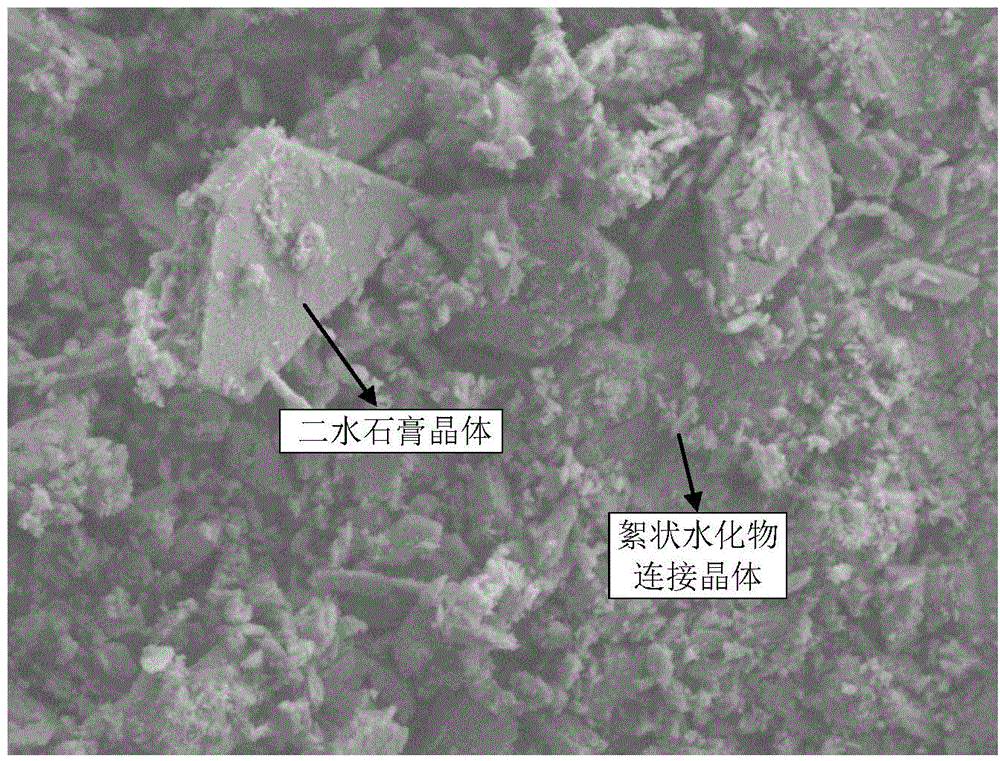

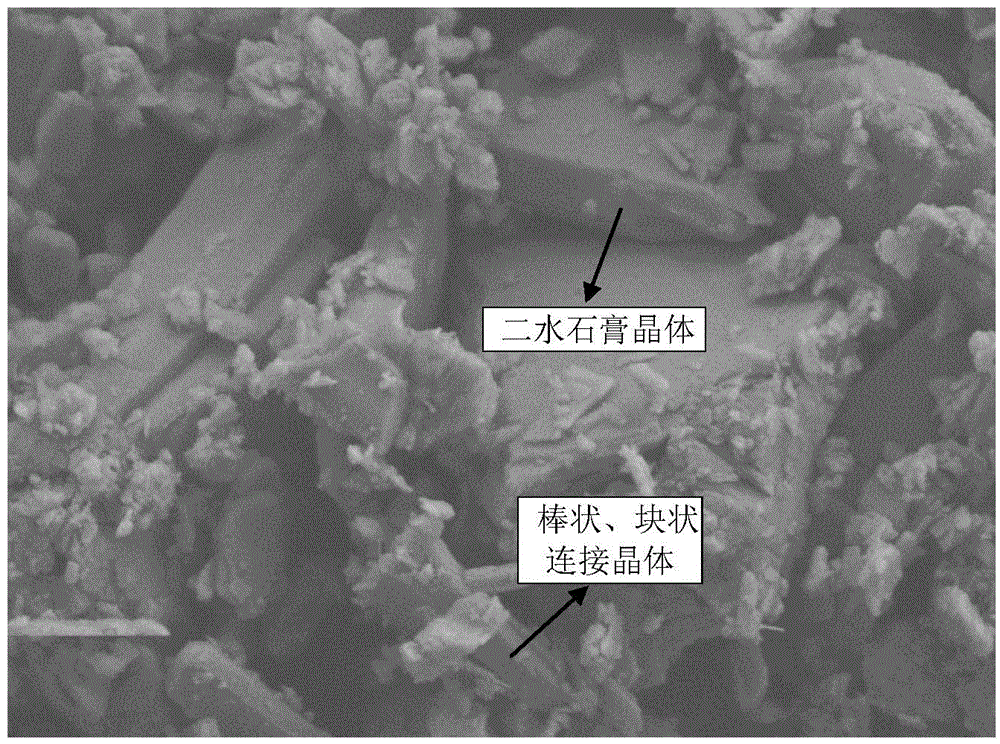

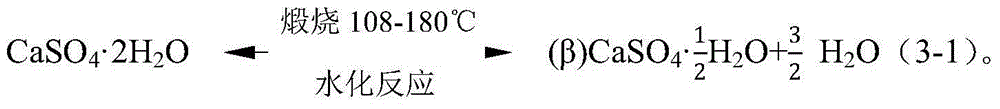

The invention discloses a light sandwich paperless gypsum board containing high-temperature phosphogypsum. The paperless gypsum board is prepared from the following raw materials in parts by weight: 10-20 parts of high-temperature phosphogypsum, 80-90 parts of high-strength alpha-phosphogypsum, 3-10 parts of lime, 3-10 parts of heavy calcium carbonate, 1-3 parts of glass fiber gridding cloth, 0.05-1 part of a composite foaming agent and 0.01-0.1 part of a composite foam stabilizer. According to the invention, the core layer takes high-temperature phosphogypsum and high-strength alpha-phosphogypsum as main raw materials for the first time, and lime and coarse whiting inorganic powder are doped to serve as filler; by means of the idea of foaming by introducing a foaming agent and a foam stabilizer, a layered cast-in-place method, a combined pouring method and an integral assembly method after layered manufacturing are adopted for preparation. The production process is simplified, dryingis easy, the prepared paperless gypsum board is not prone to mildewing, the strength of a core layer is 0.6 MPa or above, the volume weight is smaller than 550 kg / m3, the volume weight of a paperlessgypsum board wall is reduced, and the heat preservation performance of the paperless gypsum board wall is improved.

Owner:GUIZHOU KAILIN PHOSPHOGYPSUM INTEGRATION UTILIZATION

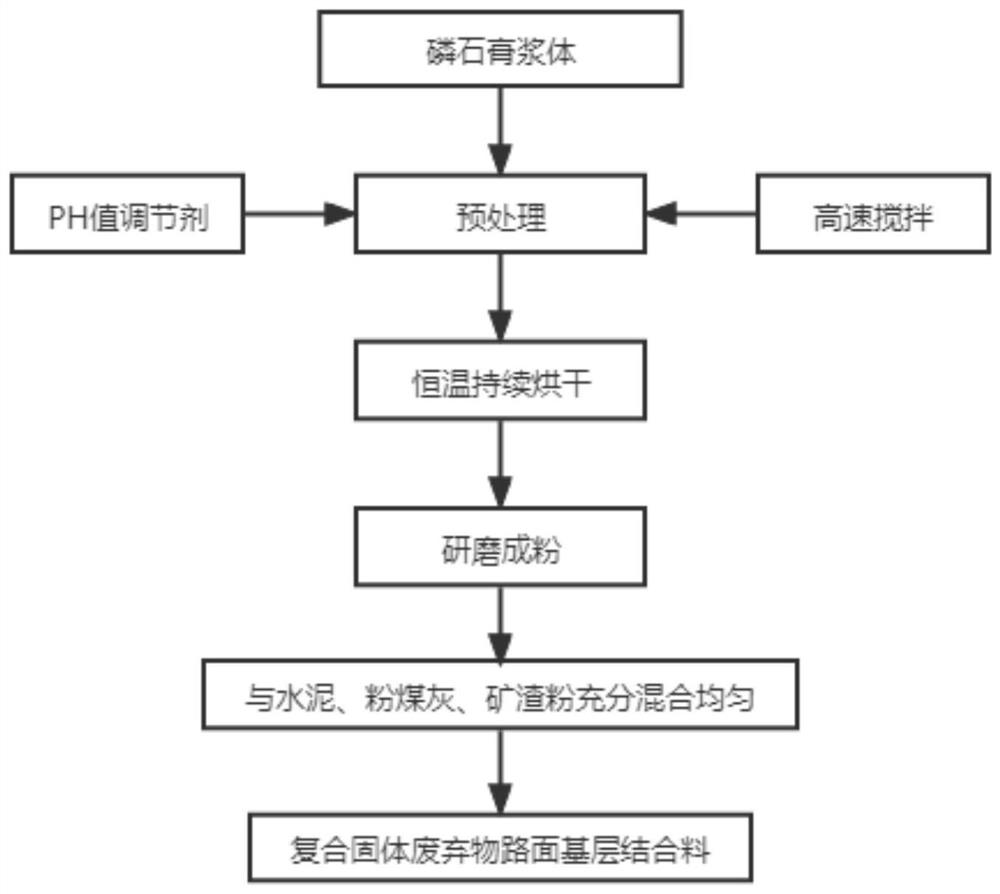

Composite solid waste pavement base binder and preparation method thereof

PendingCN114804773AAchieve recyclingAchieve environmental protectionShrinkage crackingRoad engineering

Owner:中路高科交通检测检验认证有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap