Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

19 results about "Pallet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pallet /ˈpælɪt/ is a flat transport structure, which supports goods in a stable fashion while being lifted by a forklift, a pallet jack, a front loader, a jacking device, or an erect crane. A pallet is the structural foundation of a unit load which allows handling and storage efficiencies. Goods or shipping containers are often placed on a pallet secured with strapping, stretch wrap or shrink wrap and shipped. Since its invention in the twentieth century, its use has dramatically supplanted older forms of crating like the wooden box and the wooden barrel, as it works well with modern packaging like corrugated boxes and intermodal containers commonly used for bulk shipping.

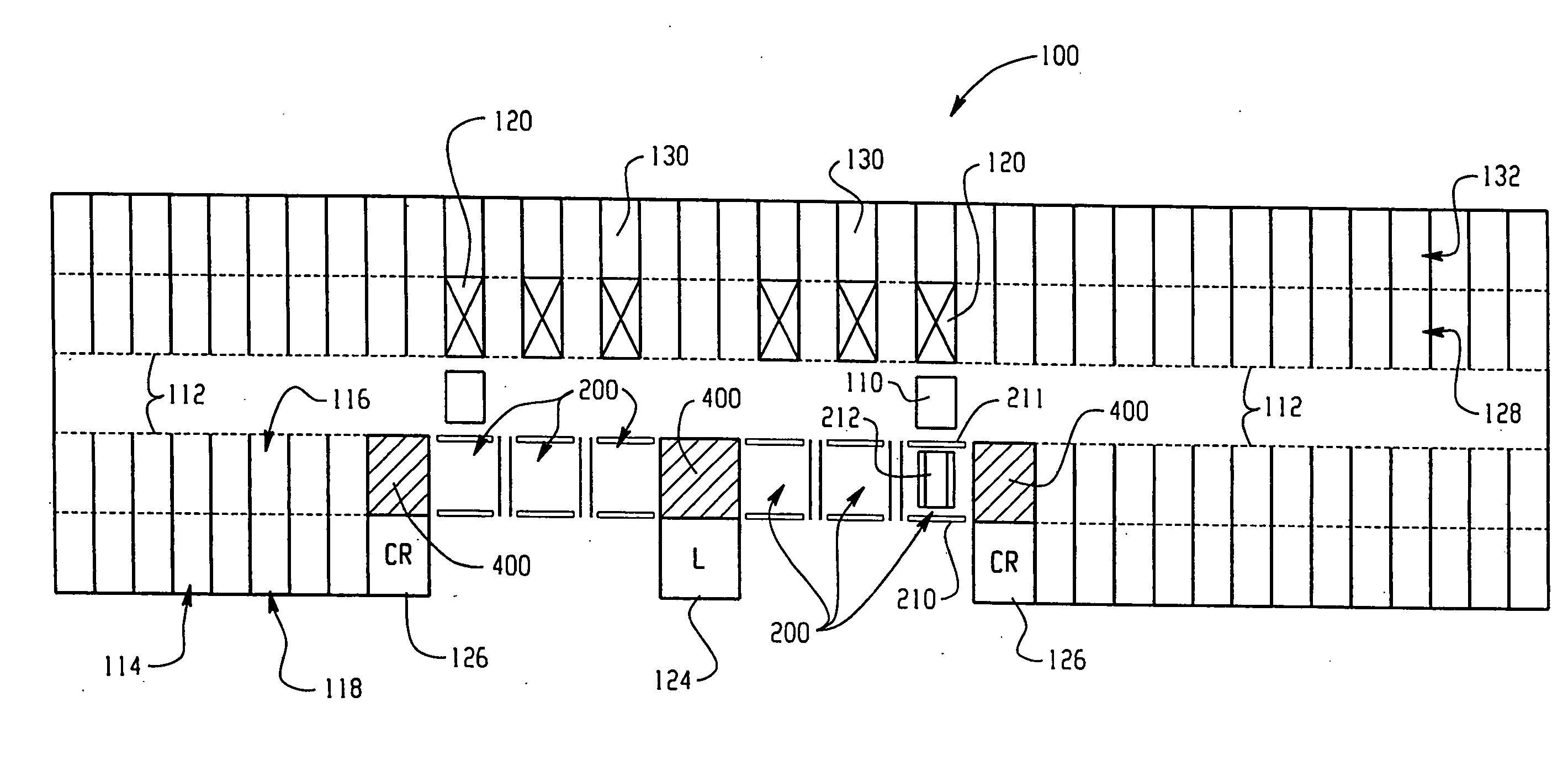

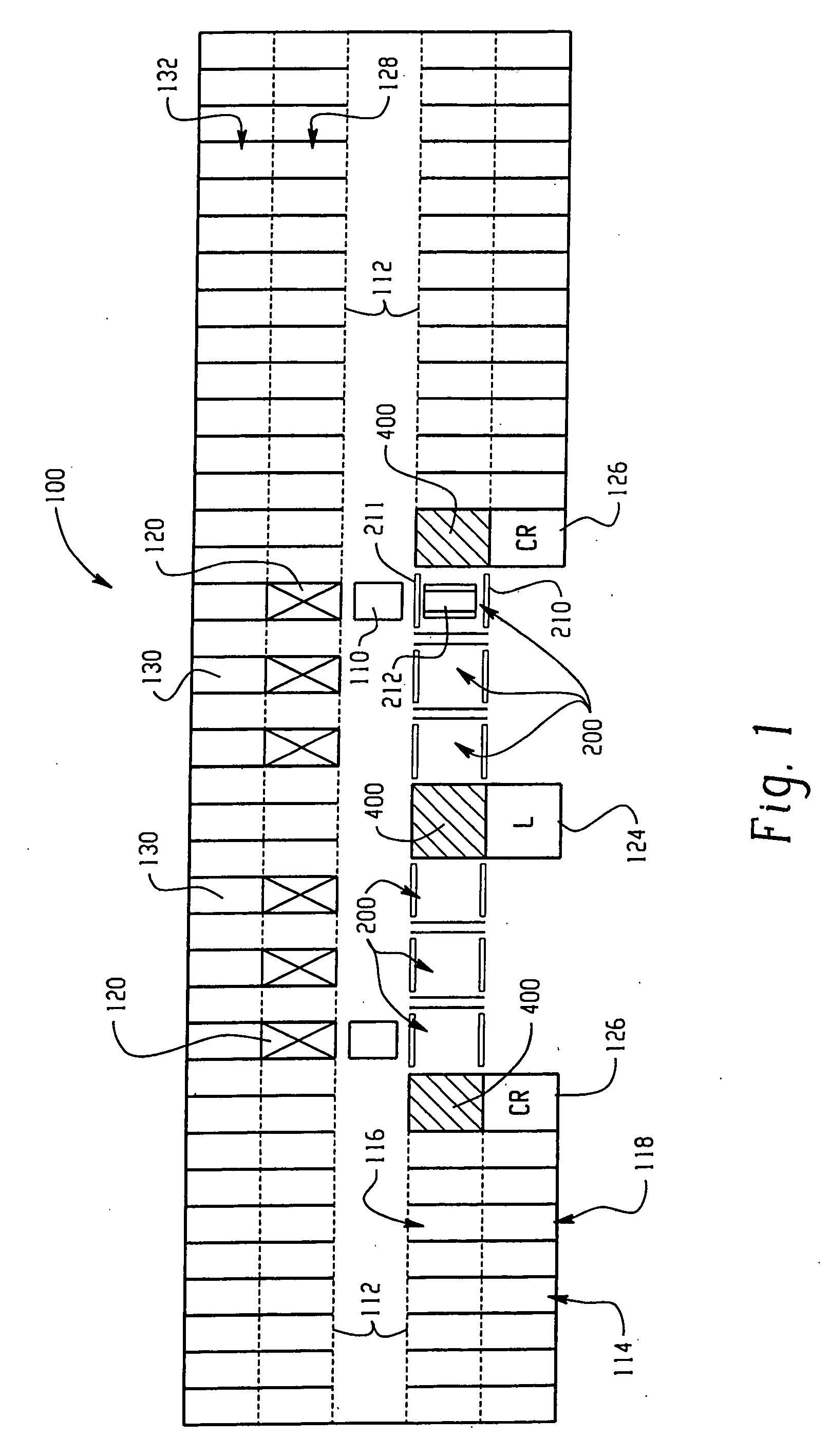

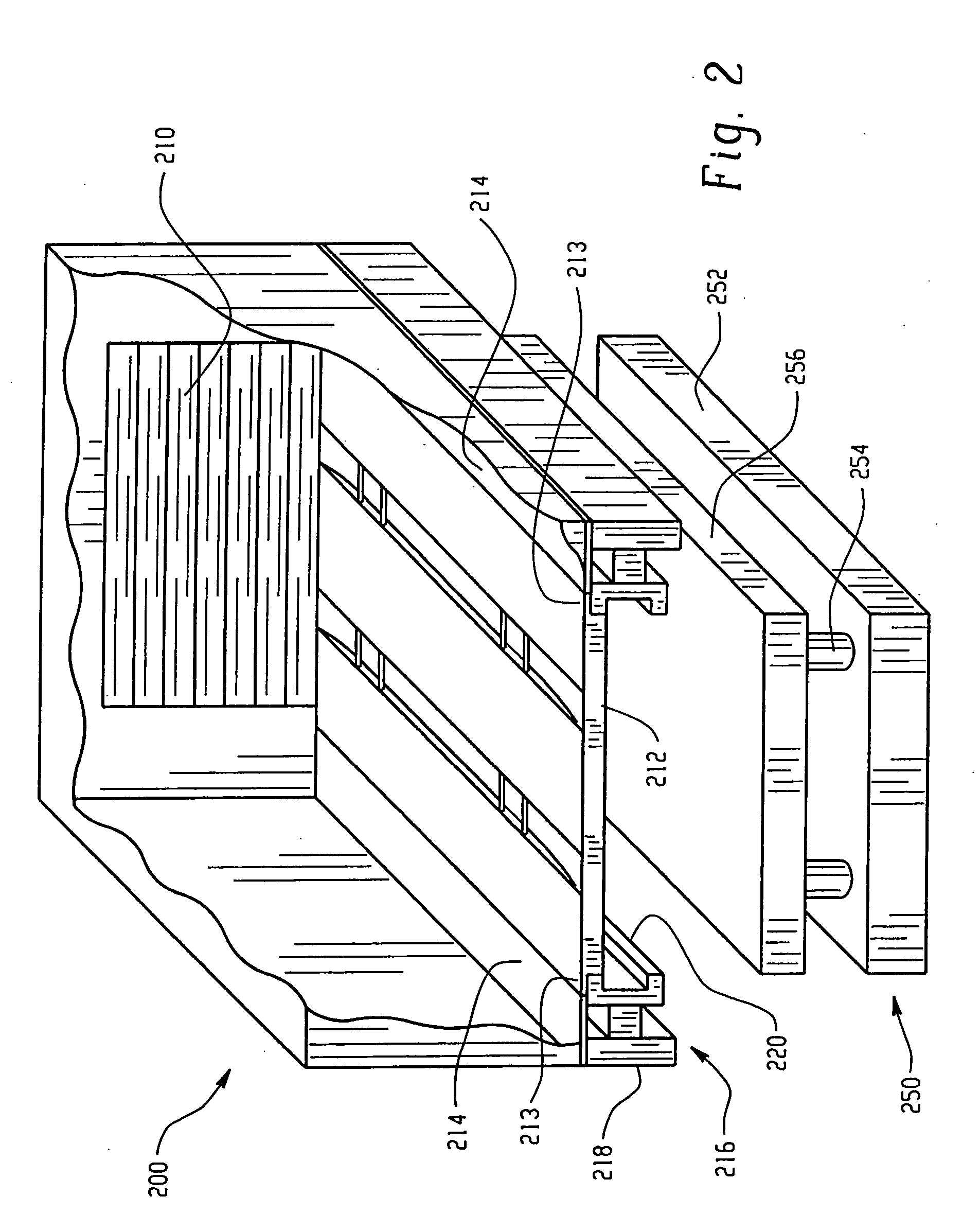

Automated parking garage

InactiveUS20050220594A1Improve efficiencyImprove performanceRefuse receptaclesLoading/unloading vehicle arrangmentTransport systemFloor level

Owner:ROBOTIC TECH ADMINISTRATION

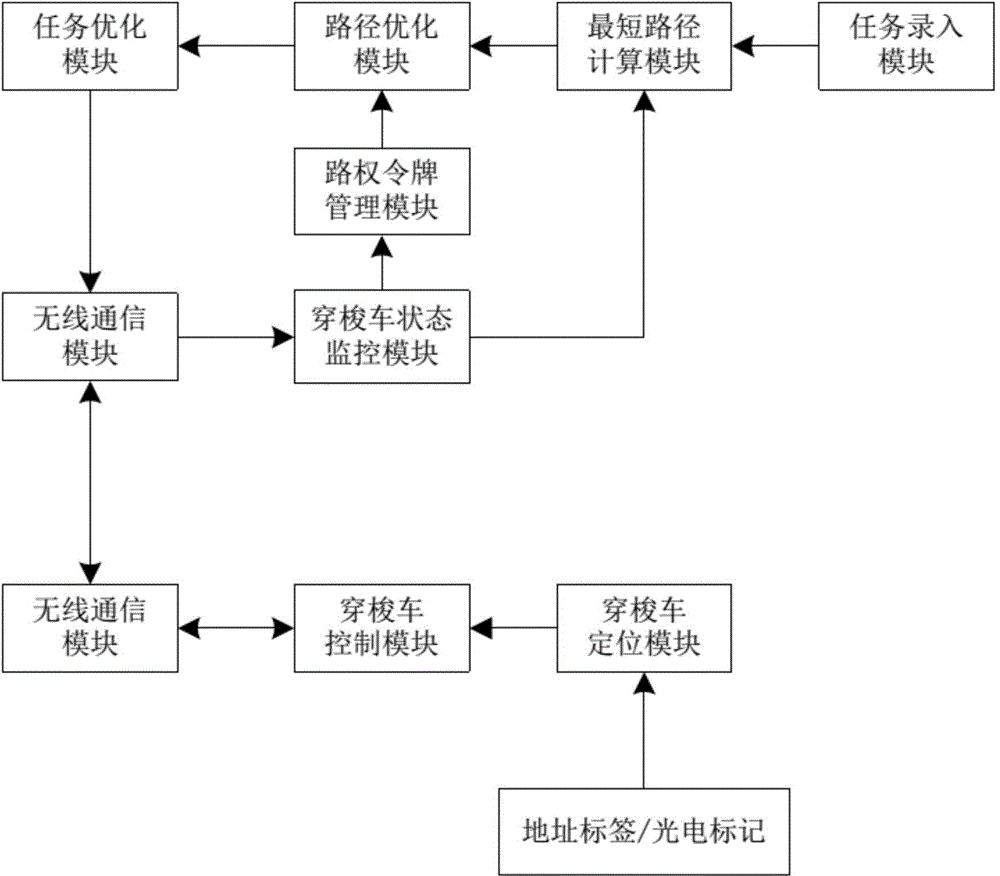

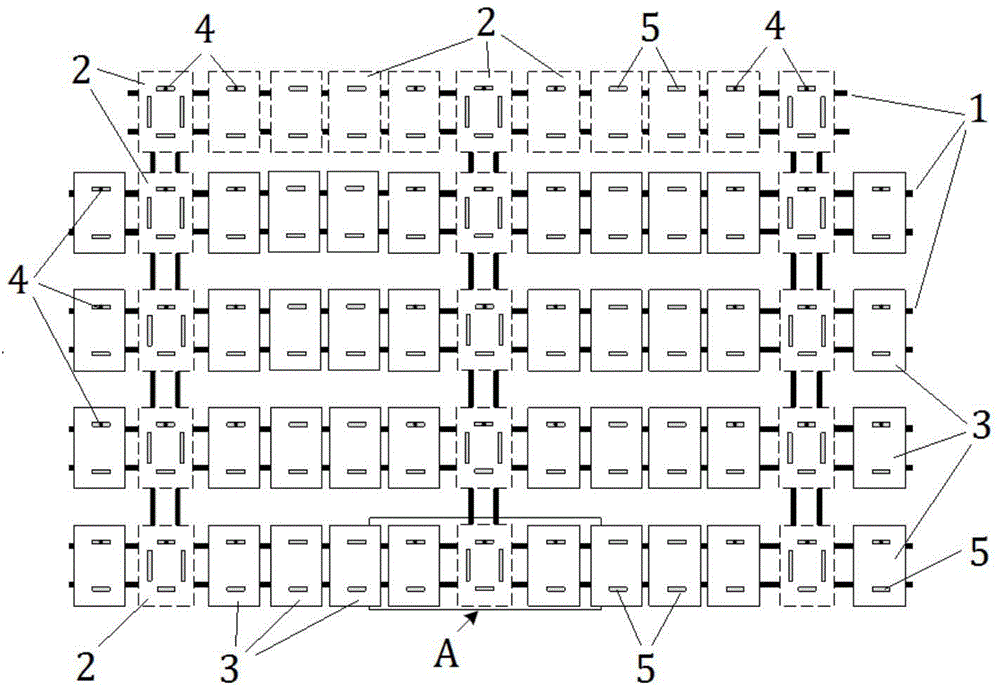

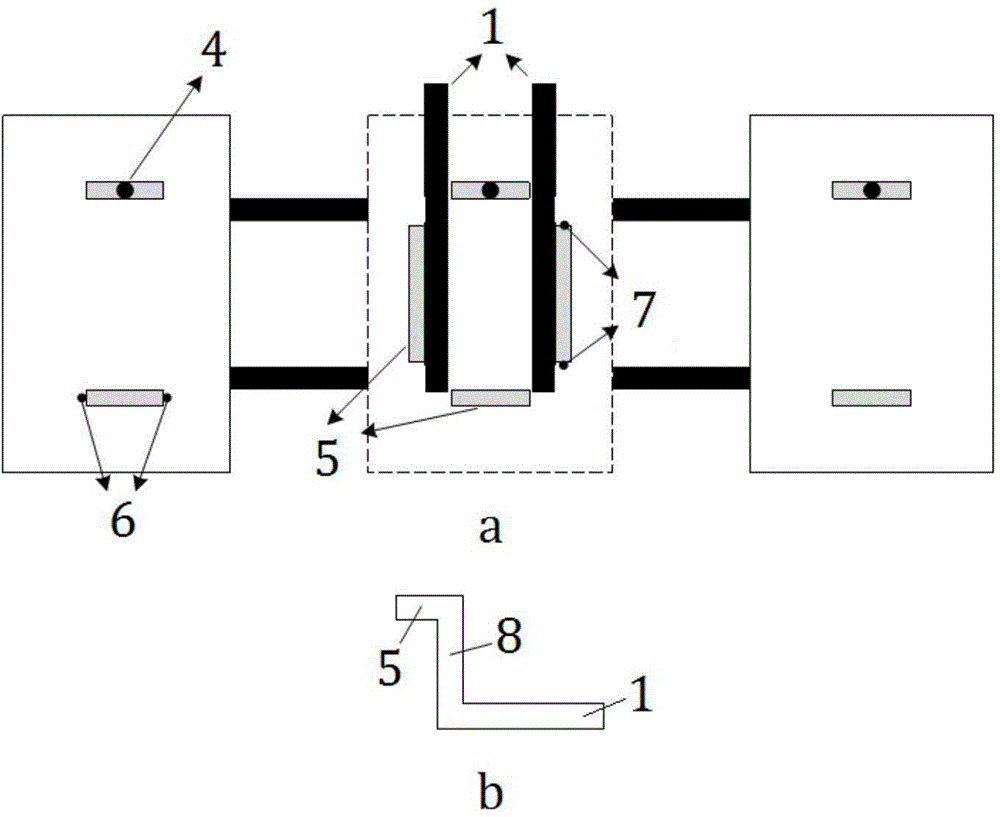

Four-directional shuttle vehicle control system based on road right tokens

ActiveCN104609086ARealize unmanned handlingImprove handling efficiencyStorage devicesIn vehicleControl system

Owner:WAP INTELLIGENCE STORAGE EQUIP SHANGHAI CORP LTD

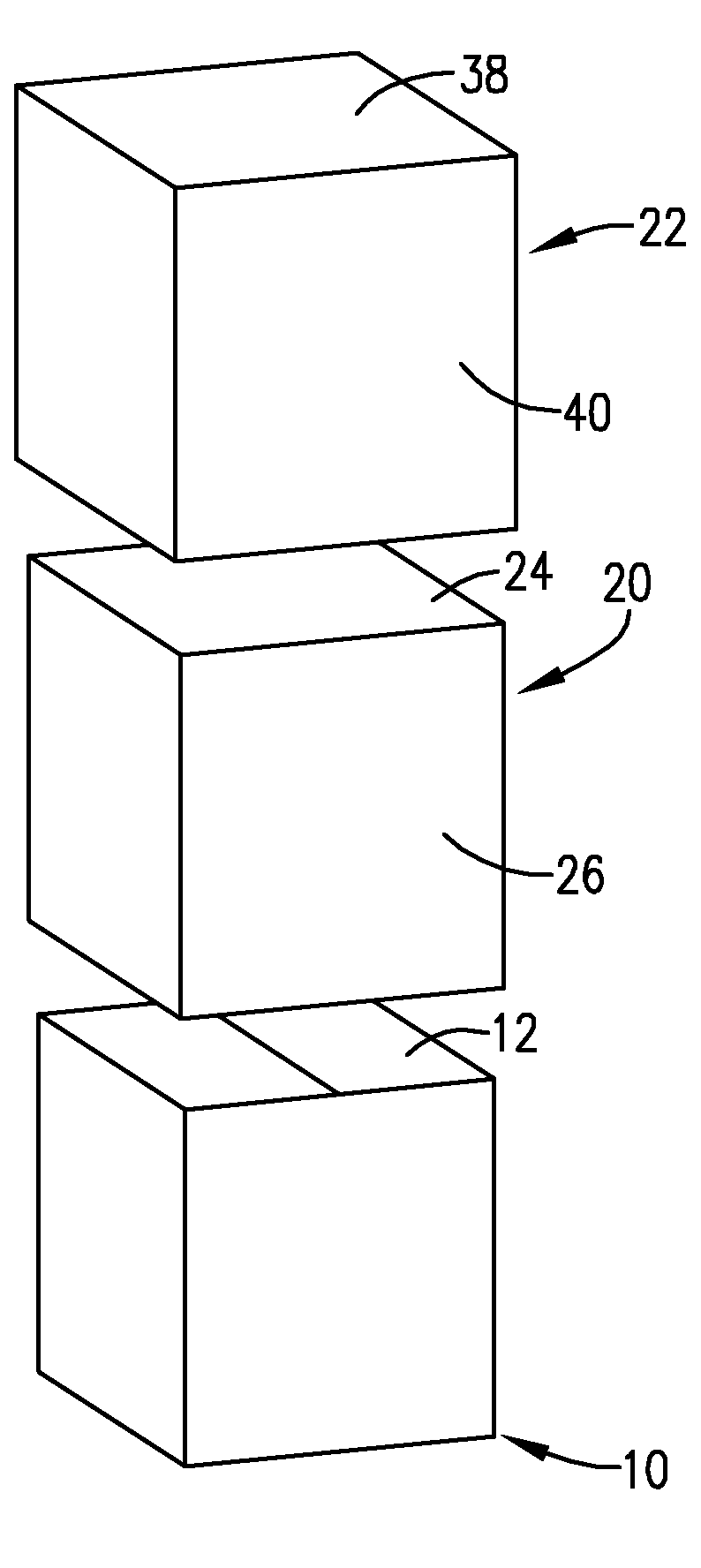

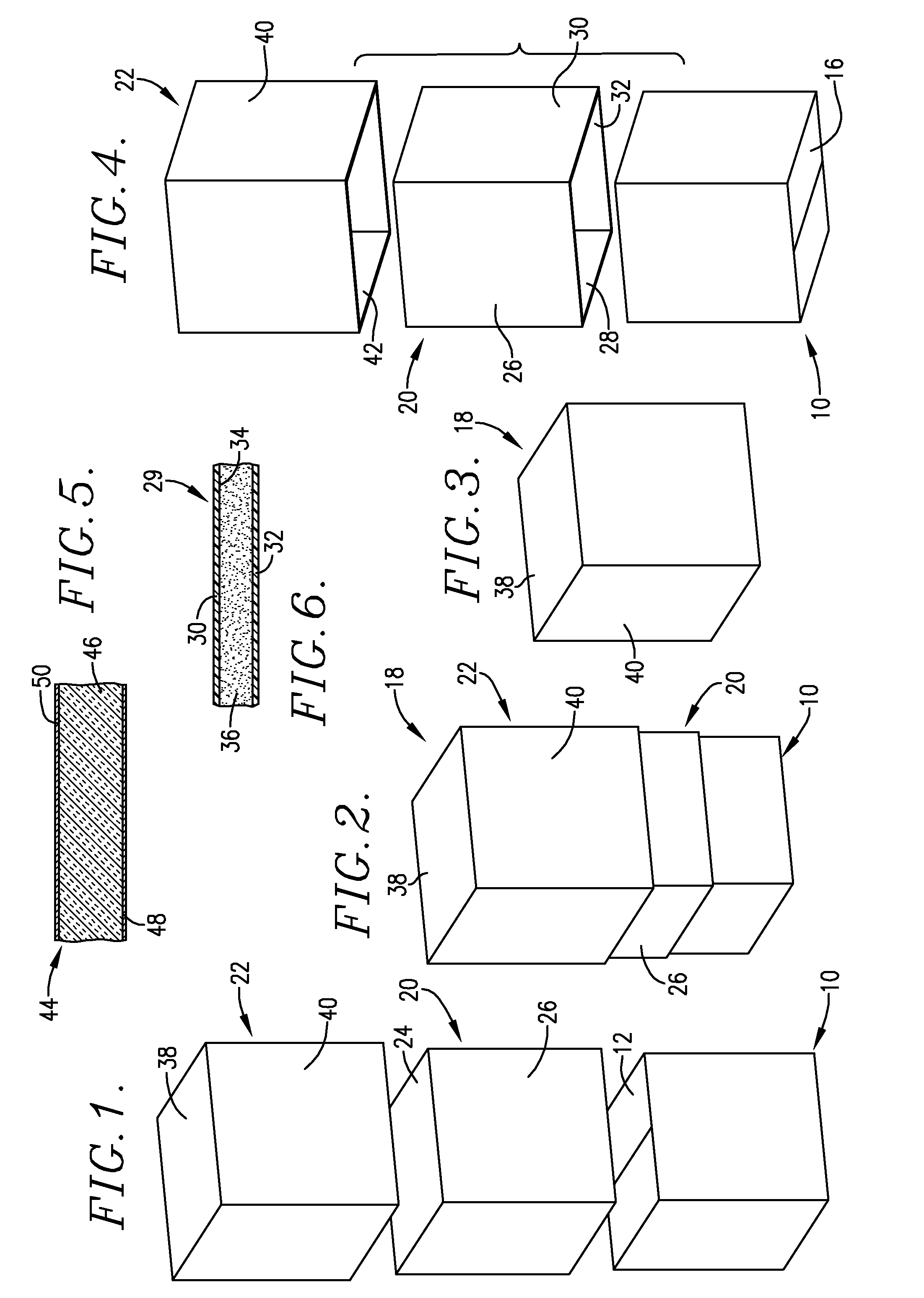

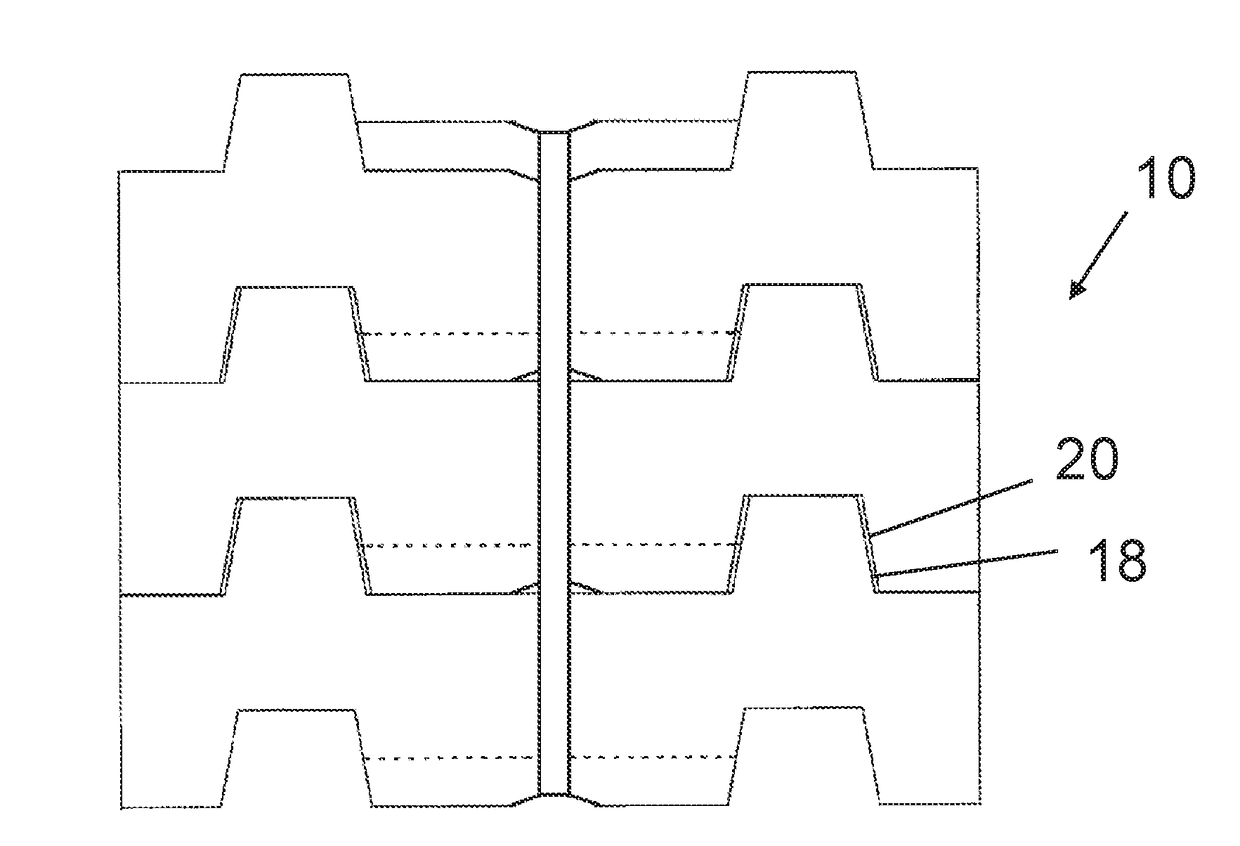

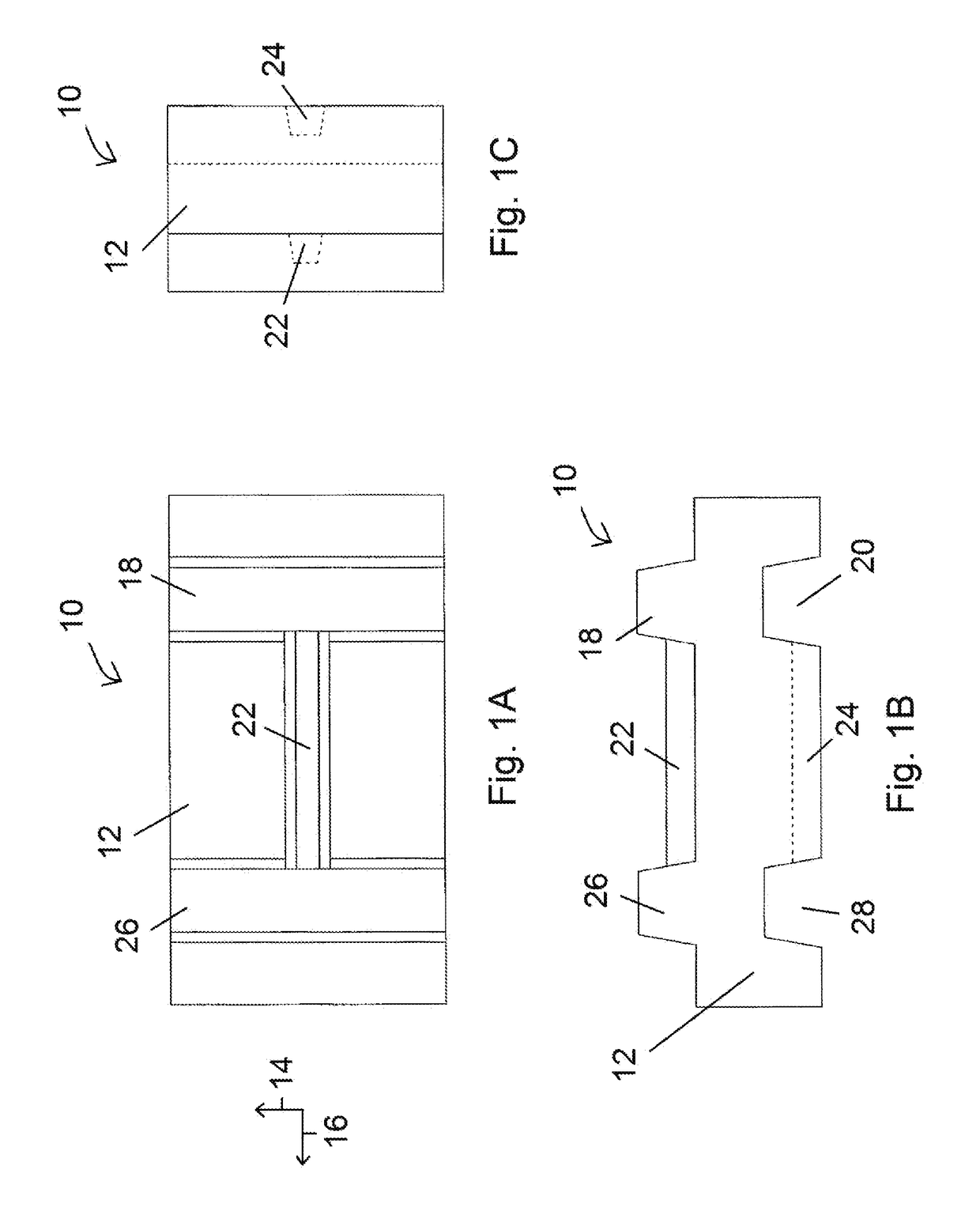

Pallet with strength plates and related methods

A pallet includes a cargo layer and a base layer. The base layer includes a pair of spaced apart end deck boards, and a pair of spaced apart connector boards orthogonal to the pair of spaced apart end deck boards, with each connector board and each end deck board having respective ends. A strength plate is coupled to each respective end of the connector boards in the base layer. Spaced apart support blocks are between the base and cargo layers, and form a gap therebetween for receiving a lifting member. First fasteners couple the cargo layer to an upper surface of the support blocks. Second fasteners couple the base layer to a lower surface of the support blocks so that the ends of the connector boards and the corresponding strength plates are coupled to a first area of the lower surface of the support blocks, and so that the ends of the end deck boards are coupled to a second area of the lower surface of the support blocks.

Owner:CHEP TECH PTY LTD

Pallet replacing device

InactiveUS20060130311A1Reduced footprintReduced space required for installationMeasurement/indication equipmentsMetal working apparatusEngineeringVertical axis

A pallet P held in a vertical position is moved from a pallet mounting surface, formed to extend vertically on a table 115 of a machine tool 101, to a pallet mounting surface formed vertically on a pallet support member 17 of a pallet changer 11. After rotationally indexing a swivel base 15 by 180 degrees about a vertical axis, a pallet P′ is moved from the pallet support member 17 to the table 115.

Owner:MAKINO MILLING MASCH CO LTD

Cover assembly for temperature-sensitive cartons or articles

Owner:GRAND DESIGN

Filtering method for suspended matters in water

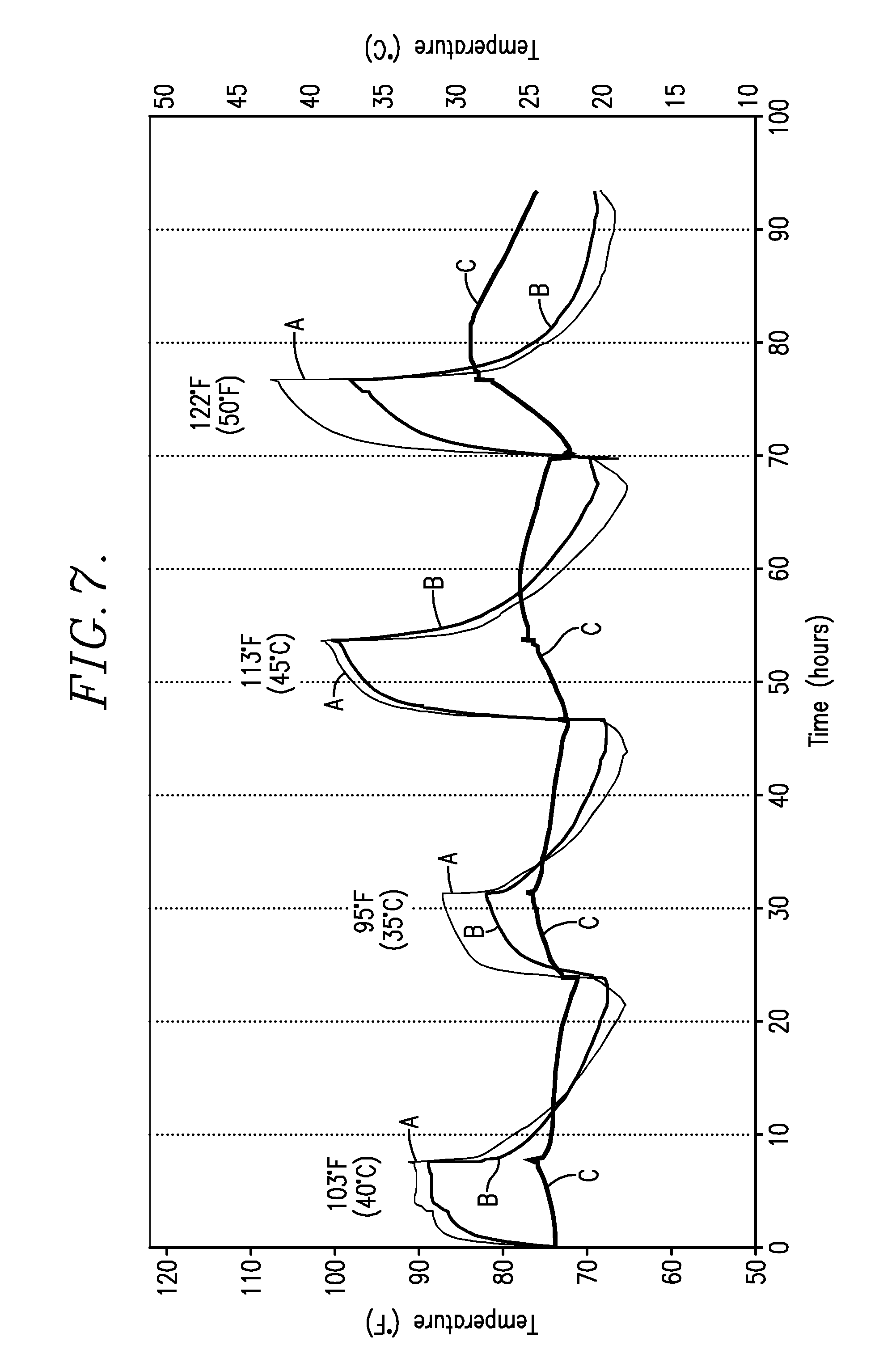

InactiveCN104155204AExtended drying timeReduce drying timesWeighing by absorbing componentFiltrationDrying time

Owner:广州衡创测试技术服务有限公司

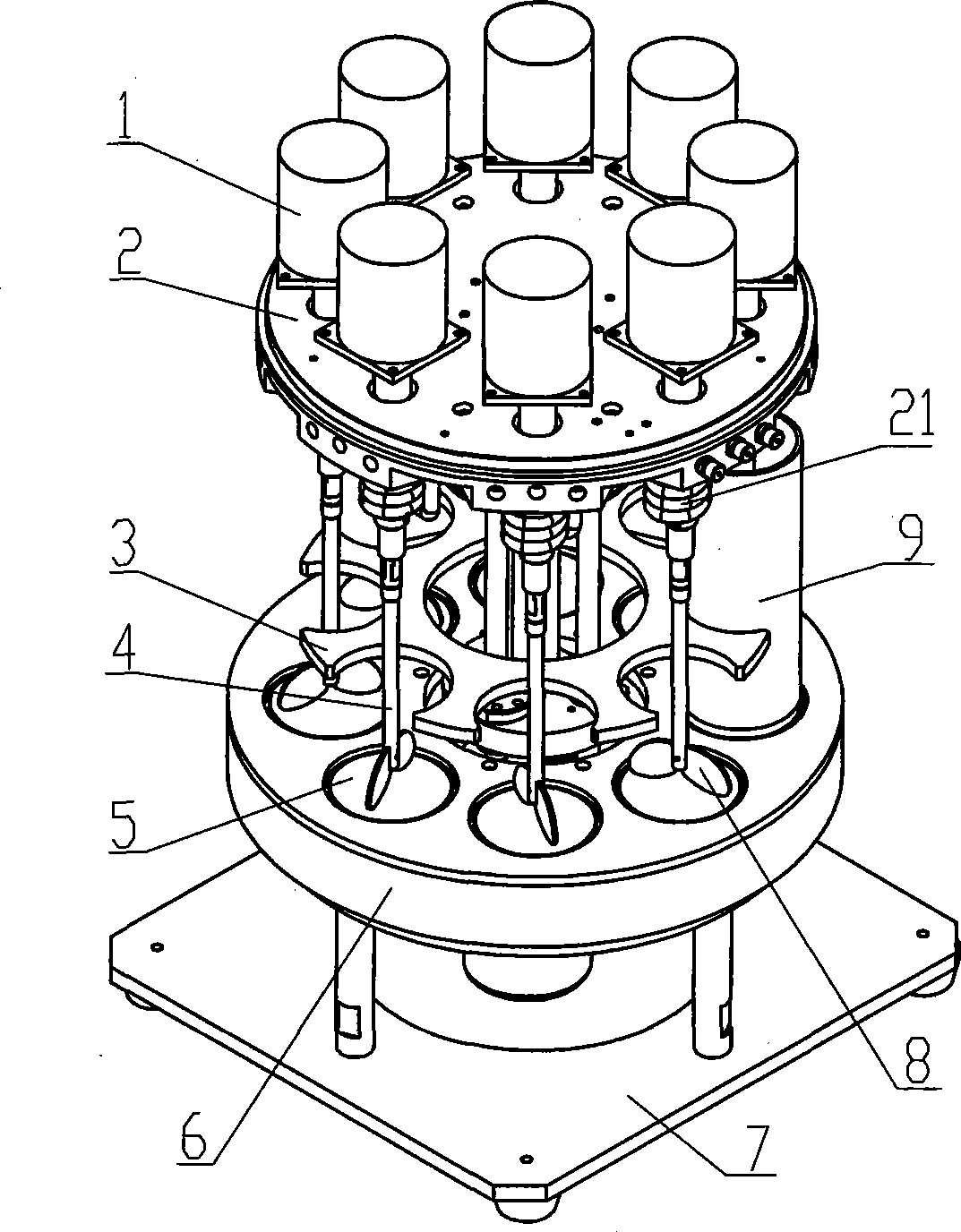

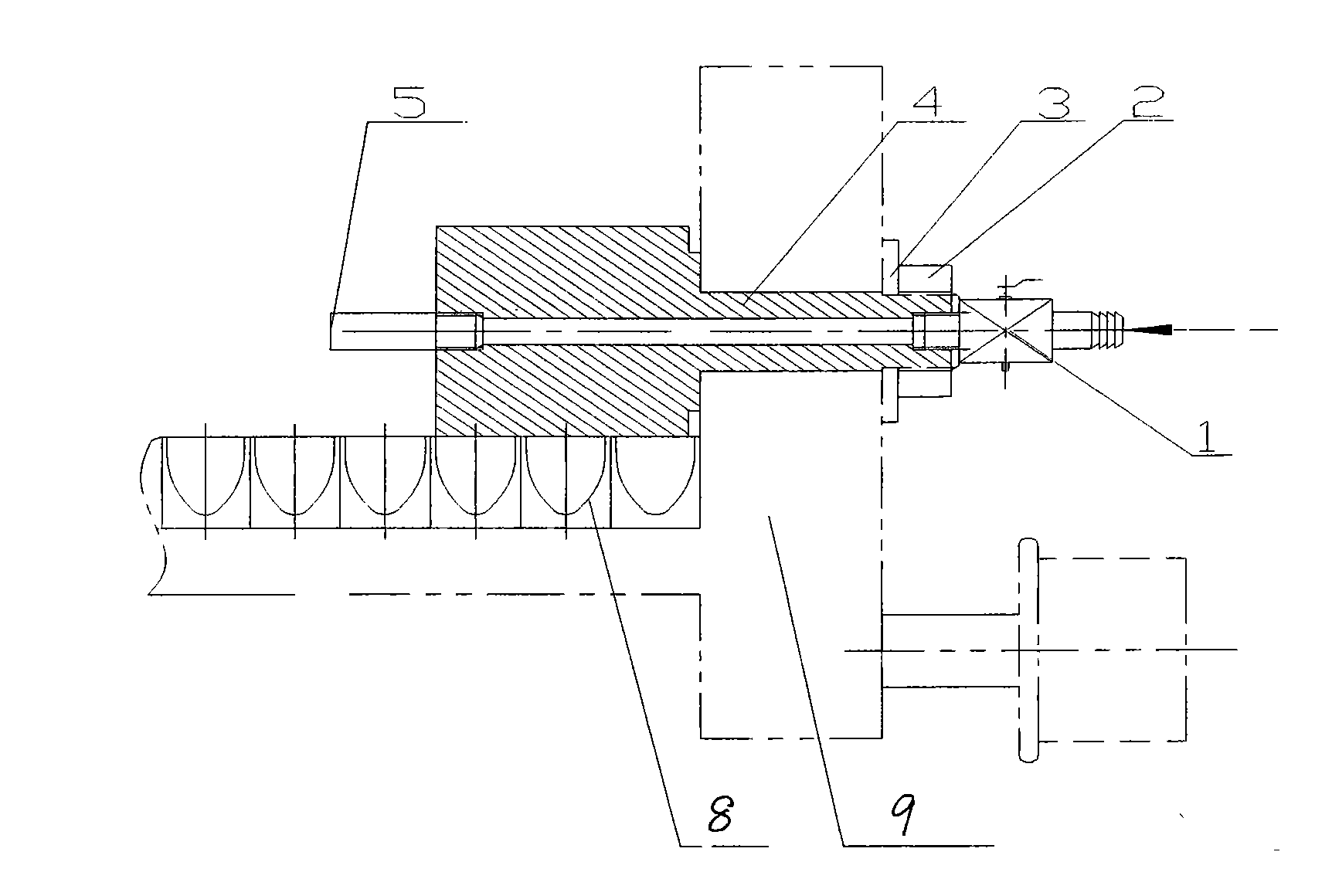

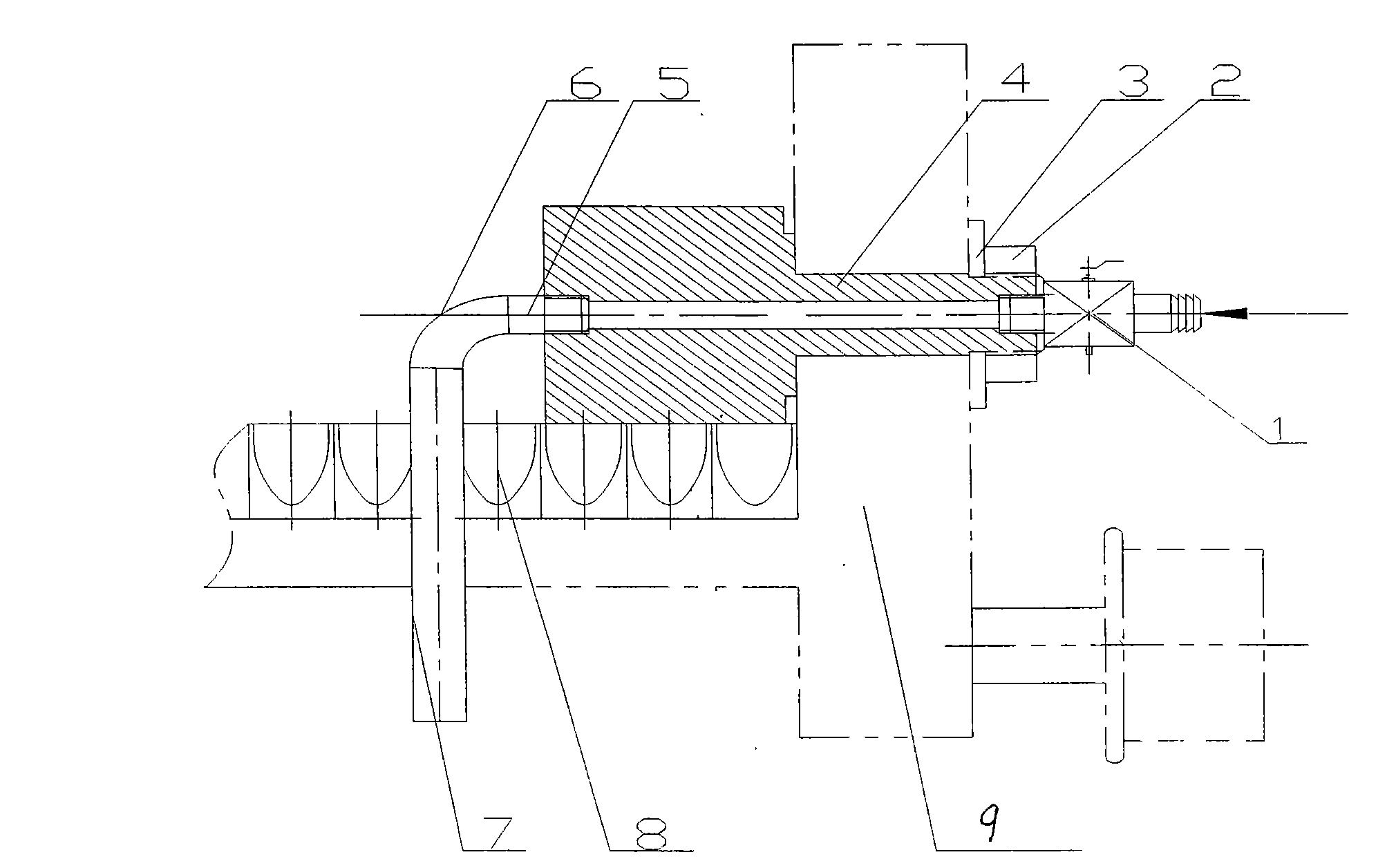

Parallel polymerization synthesis device

InactiveCN101362071AEasy to useSave research timeRotary stirring mixersMixer accessoriesResearch efficiencyReaction temperature

Owner:深圳市新和创智能科技有限公司

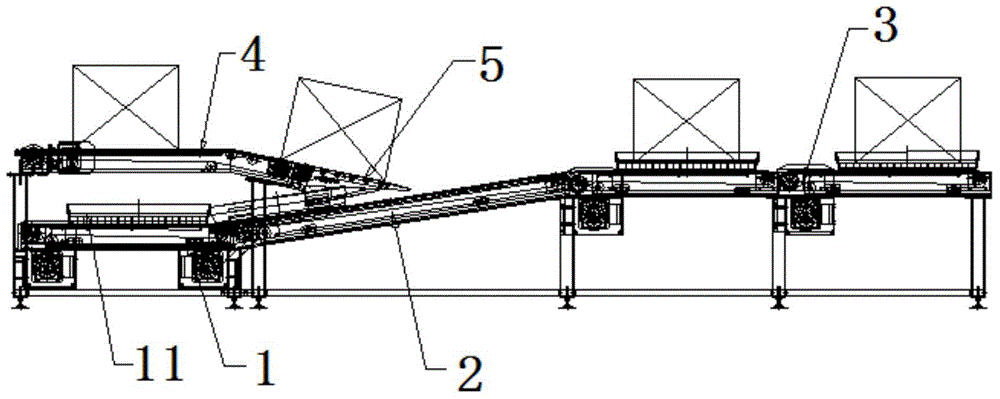

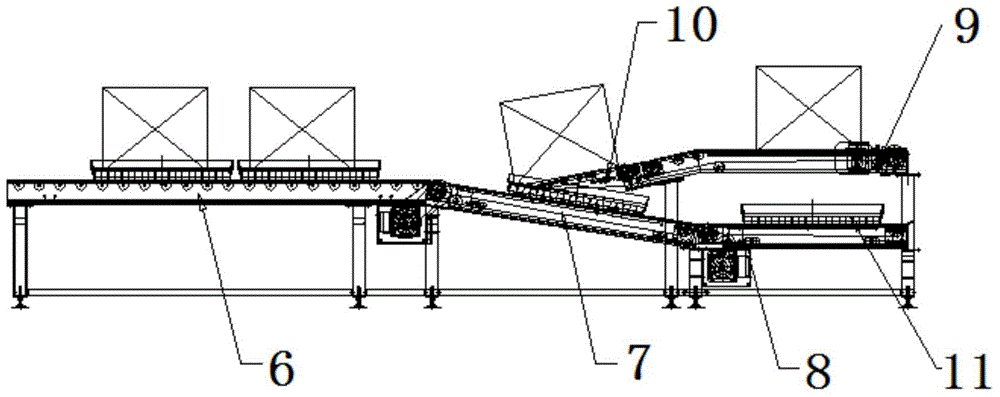

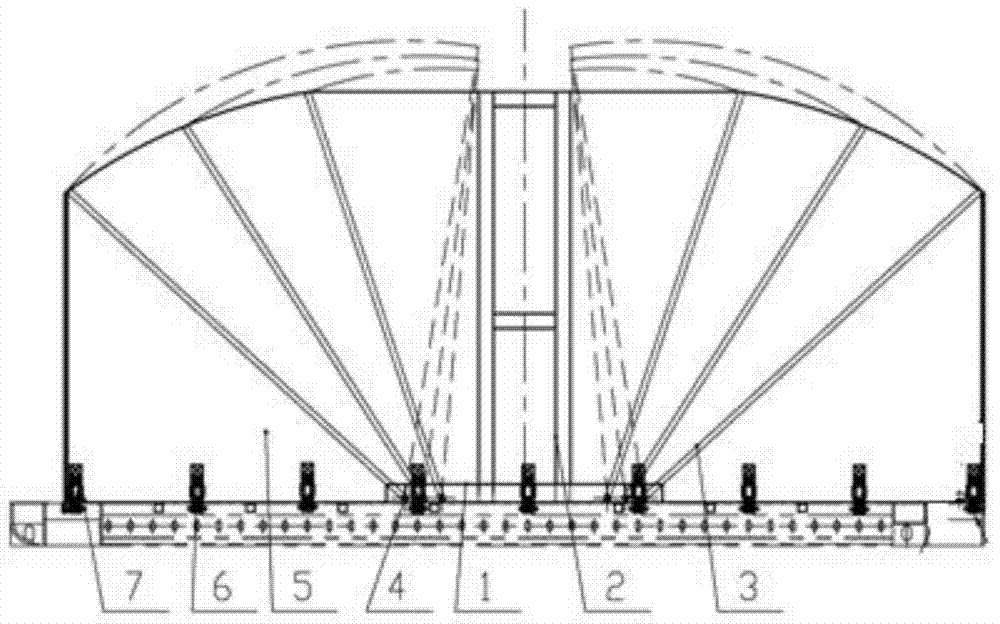

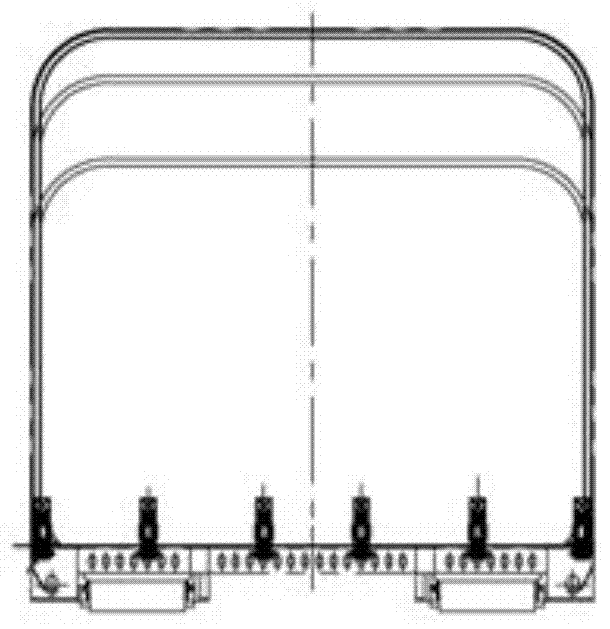

Building block off-line stacking system

The invention discloses a building block off-line stacking system. The building block off-line stacking system is characterized by comprising a finished product conveyor (2), a plate lifting machine (3), a supporting plate returning machine (4), a stack conveying machine (5), a stacking machine (6), a pallet separating machine (7) and a palletizing machine (8), the finished product conveyor (2), the plate lifting machine (3) and the supporting plate returning machine (4) are arranged in sequence, the stacking machine (6) is installed above the supporting plate returning machine (4), the stack conveying machine (5) penetrates through the lower portion of the stacking machine (6), the pallet separating machine (7) is arranged at one end of the stack conveying machine (5), one end of the supporting plate returning machine (4) is connected with the plate lifting machine (3), and the other end of the supporting plate returning machine (4) is connected with the palletizing machine (8). The building block off-line stacking system is a special stacking system which can operate independently and is suitable for stacking well maintained building blocks produced in factories, capable of improving the automation degree of building block production and relieving the labor intensity of workers, low in investment cost, high in working efficiency and suitable for large-scale popularization.

Owner:JIANGSU TENGYU MASCH MFG CO LTD

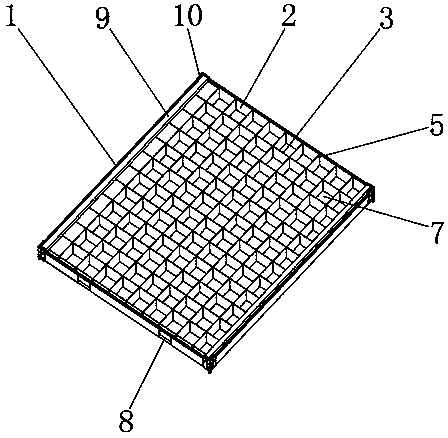

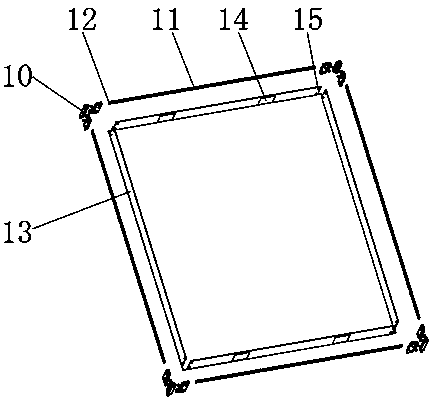

Pallet system used for plasma dry etching

InactiveCN105448776AEasy to disperseIncrease etch rateElectric discharge tubesSemiconductor/solid-state device manufacturingMetallurgyCvd graphene

The invention relates to the technical field of semiconductor processing and provides a pallet system used for plasma dry etching, which introduces a grapheme material or grapheme composite material layer to improve the surface heat dissipation capability and the temperature uniformity of a wafer. The pallet system comprises an aluminum pallet, helium hole, a sealing ring, a cover plate and the embedded grapheme material (or grapheme composite material) layer high in heat conductivity. The pallet system has the advantages and active effects that: the high-heat-conductivity grapheme material or grapheme composite material are used in the pallet system used for the r plasma dry etching, the instant heat dissipation capability of the wafer in the etching process is substantially improved, the temperature uniformity of the surface of the wafer is conveniently controlled, the qualified rate of etched products is improved, and the operation window of the etching process is enlarged.

Owner:SINO NITRIDE SEMICON

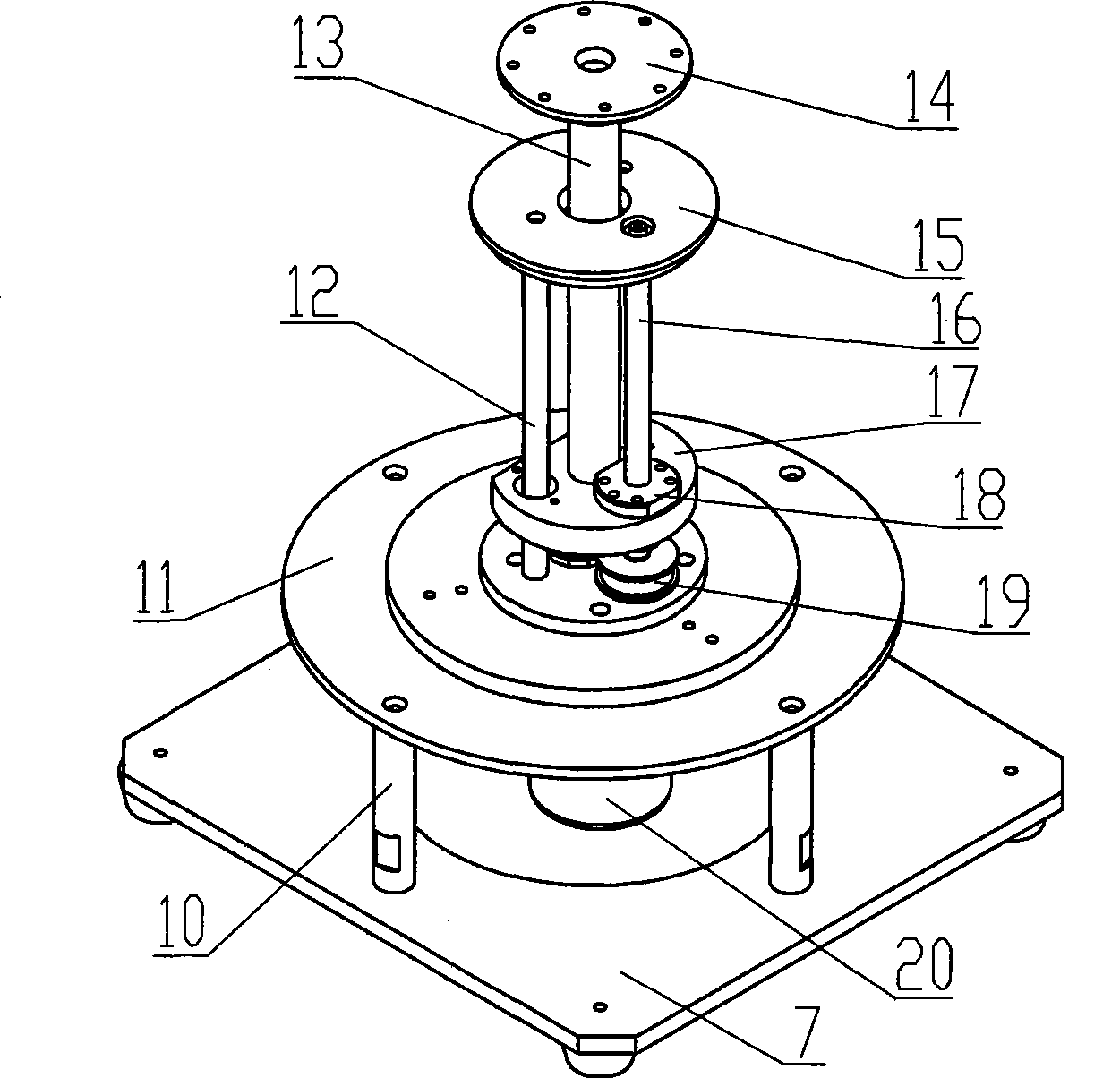

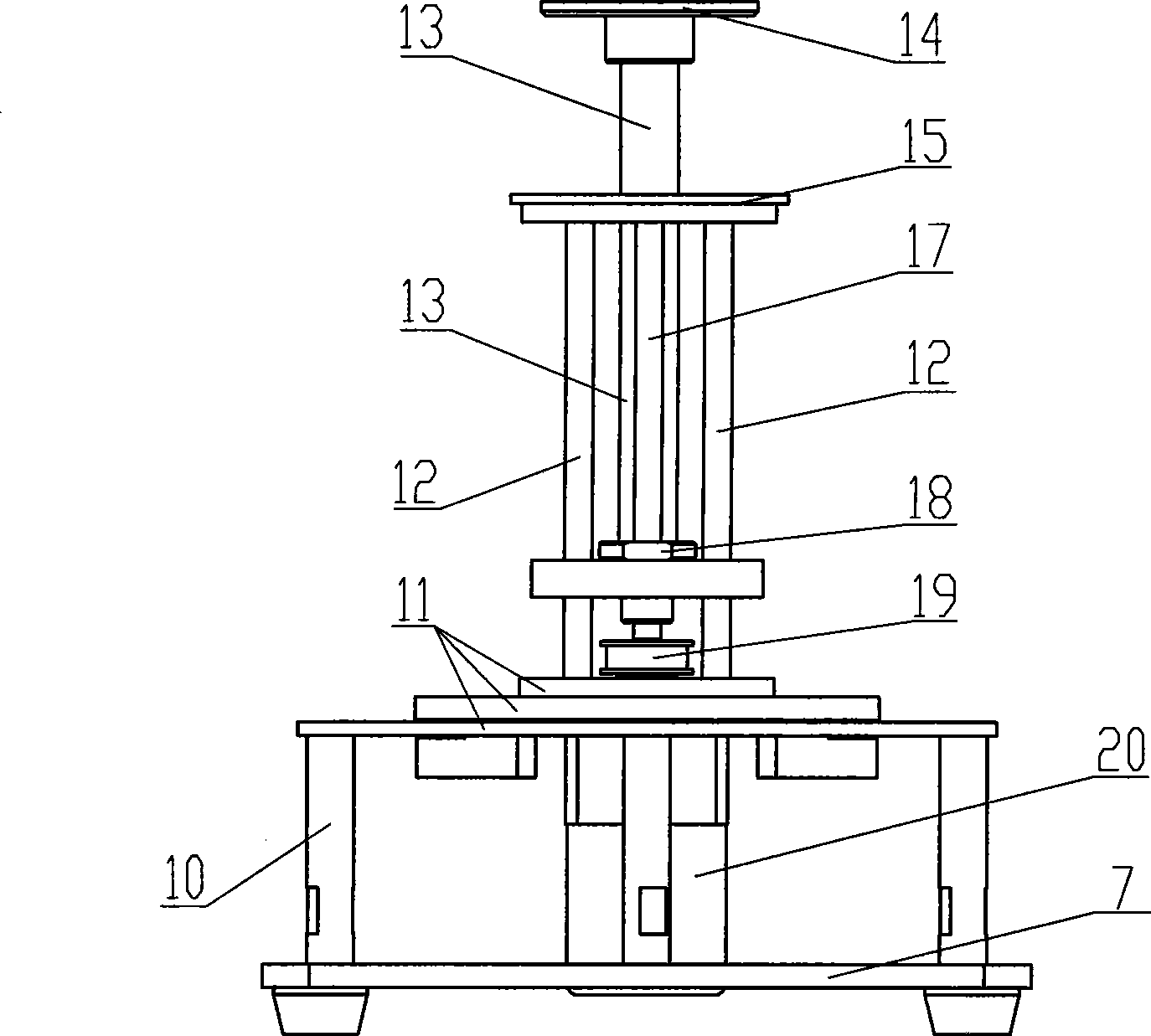

Self rotation device for vacuum cavity

ActiveCN103807119ASolve the sealing problemTroubleshoot spinning crafting issuesSpring motorMachines/enginesGear wheelEngineering

The invention discloses a self rotation device for a vacuum cavity. The self rotation device comprises a rotation tray, a casing and a spiral clockwork spring, an internal and outer inclined tooth gear, a directional rotation fork and a rotating shaft, wherein the internal and outer inclined tooth gear is an annular wheel, internal and external inclined teeth are respectively arranged on the inner and outer side surfaces of the annular wheel, the inclination directions of the internal and external inclined teeth are opposite, the upper end of the rotating shaft is fixedly arranged on the rotation tray, the lower end of the rotating shaft sequentially passes through the internal and external inclined tooth gear, the clockwork spring and a case, the directional rotation fork comprises a plurality of stop parts, the center of the directional rotation fork is fixed onto the rotating shaft, the tail ends of the stop parts are respectively butted with the internal inclined teeth, the internal end of the spiral clockwork spring is fixedly arranged on the rotating shaft, the outer end of the spiral clockwork spring is fixedly arranged on the casing, a plurality of pallets are arranged on the inner side surface of the casing, and the tail ends of the pallets are butted with the external inclined teeth. The self rotation device for the vacuum cavity has the advantages that the structure is simple, and in addition, the rotation smoothness and the airtightness requirement during the rotation can be met.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

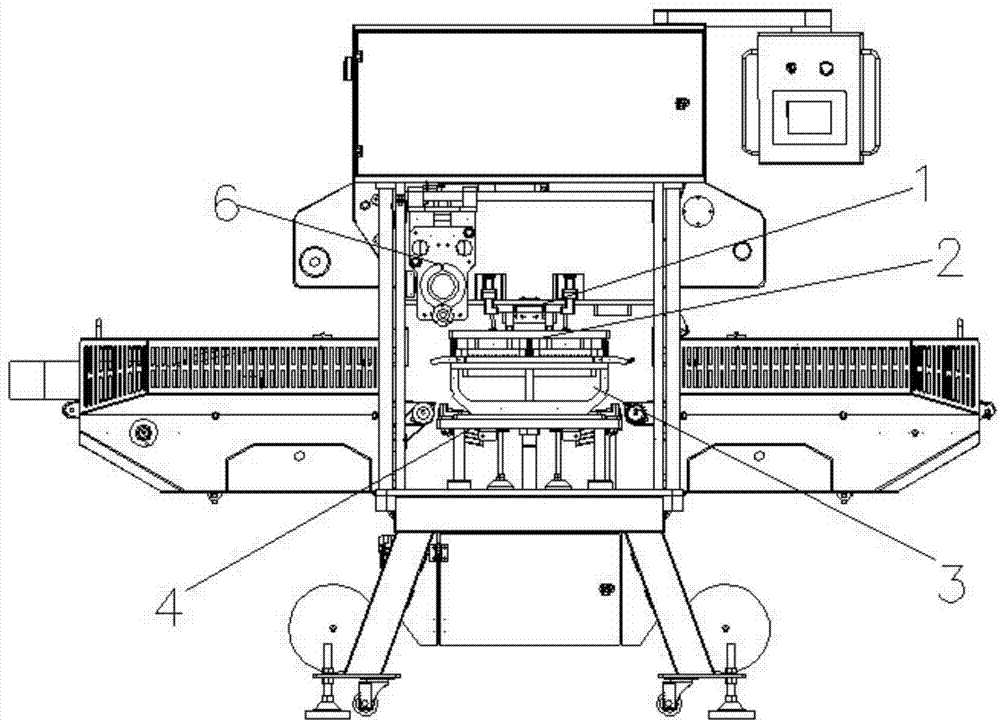

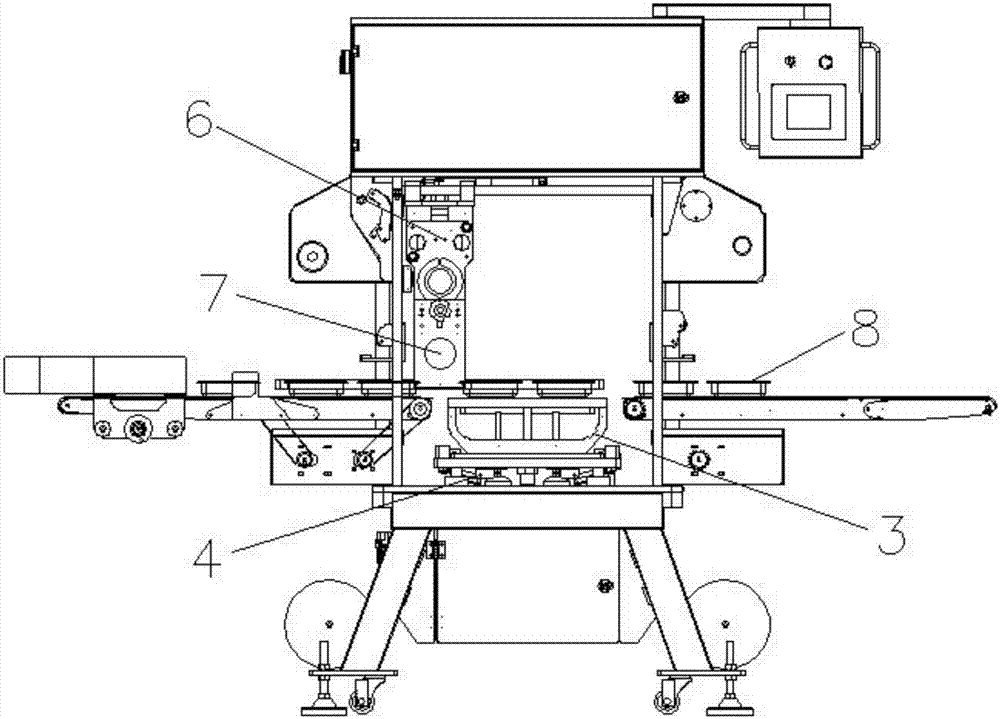

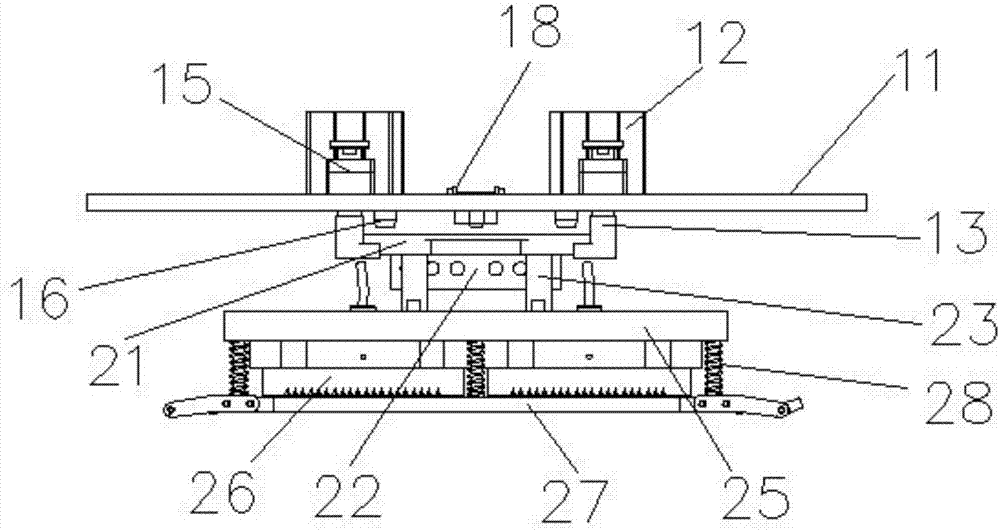

Online tray automatic sealing machine

Owner:欧华包装设备(河源)有限公司

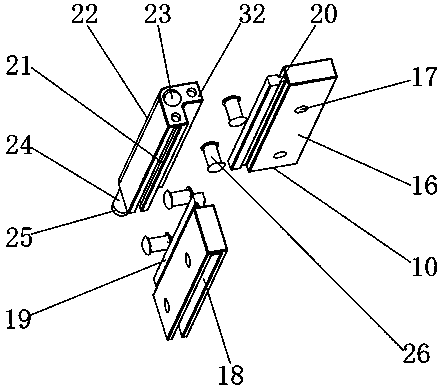

Wheel sleeve part feeding device

ActiveCN109335681ASimple structurePrecise positioningTotal factory controlConveyor partsHorizontal axisEngineering

The invention discloses a wheel sleeve part feeding device. The wheel sleeve part feeding device comprises a three-axis truss robot, a hand push trolley, a hand push trolley positioning device and a plurality of pallets. The three-axis truss robot is composed of an XYZ linear module and a pneumatic clamping jaw. The XYZ linear module comprises a horizontal axis X, a longitudinal axis Y and a vertical axis Z. The pneumatic clamping jaw is mounted at the lower end of the vertical axis Z and used for grabbing and releasing parts. The hand push trolley positioning device is arranged on the groundsuitable for the three-axis truss robot and used for limiting the hand push trolley at the designated location to ensure that the three-axis truss robot can grab all the parts and placing the pallets.The wheel sleeve part feeding device has the advantages of good universality and high efficiency.

Owner:YUHUAN CNC MACHINE TOOL

Automatic pallet combination and separation system

Owner:JIN HOUNG FUH (CHUZHOU) CONVEYING EQUIP CO LTD

Folding tarpaulin of flat pallet

Owner:BEIJING SANXING AUTOMOBILE

Pallet-less brick

ActiveUS20180244449A1Eliminate useTransported quickly and efficientlyRigid containersDamagable goods packagingBrickEngineering

Owner:BALL CORP

Sintering pallet grate bar zone negative pressure measuring device

ActiveCN101660960AFluid pressure measurement using pressure-sensitive liquidPressure difference measurement between multiple valvesEngineeringScrew thread

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Novel workpiece drying device

InactiveCN107906882AAchieve dryingEvenly heatedDrying chambers/containersDrying machines with non-progressive movementsDistal portionOptical axis

Owner:衢州菁英科技有限公司

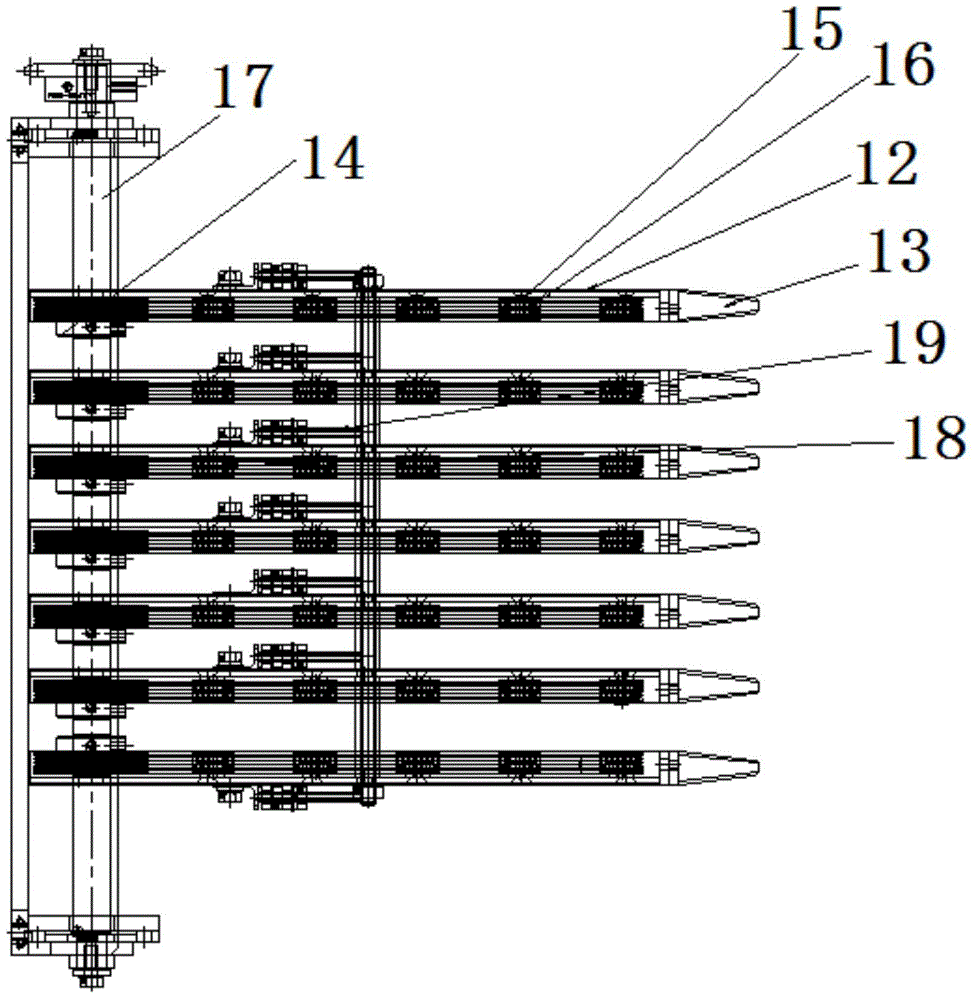

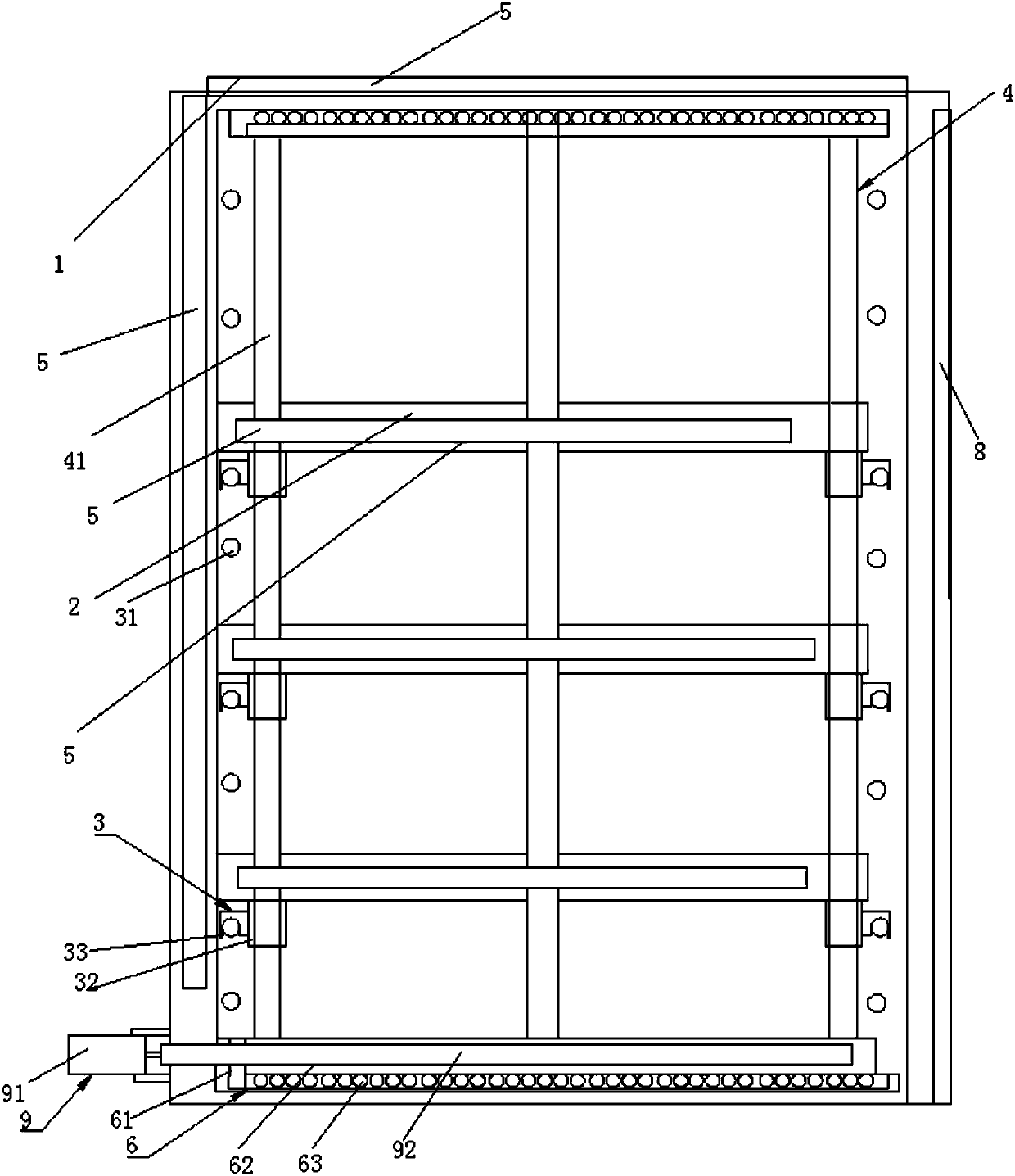

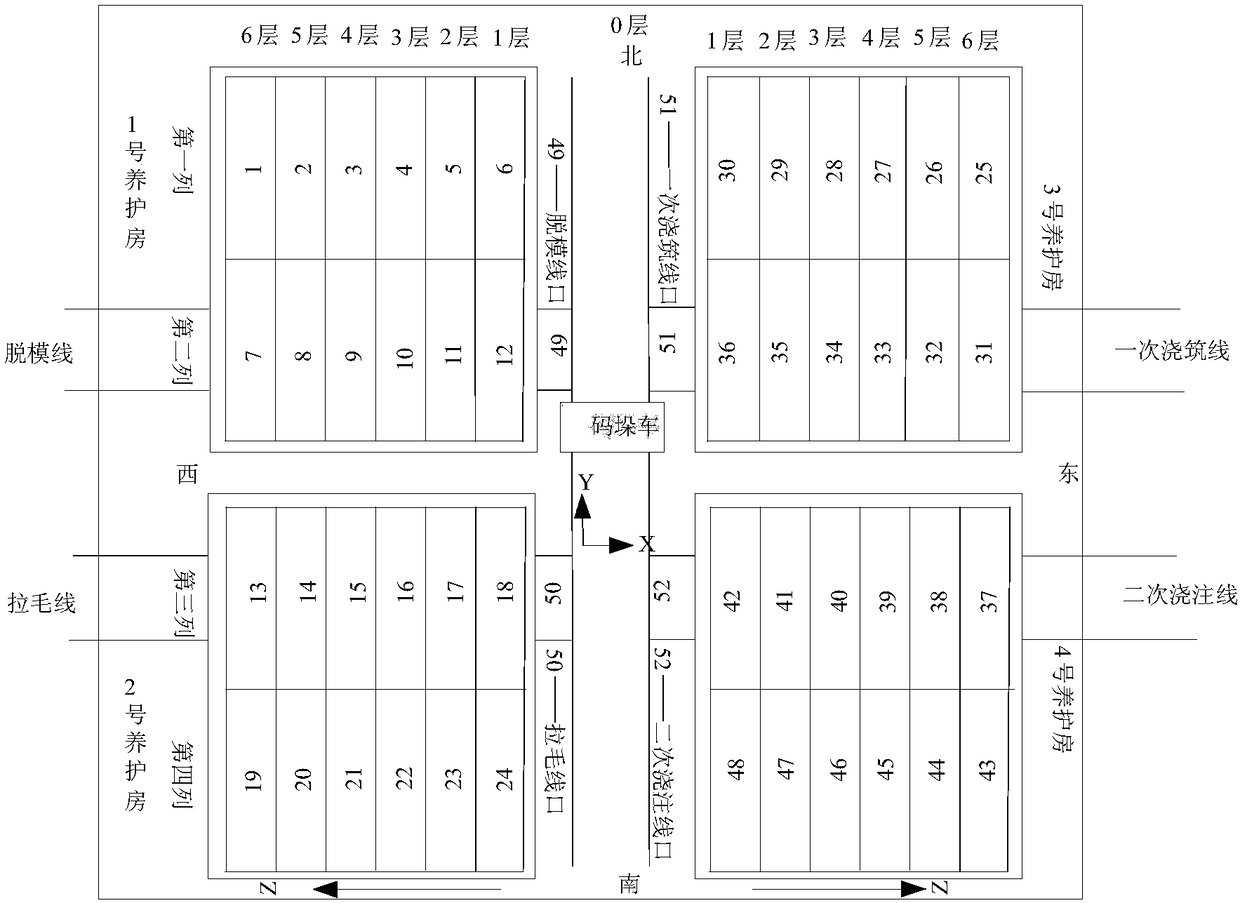

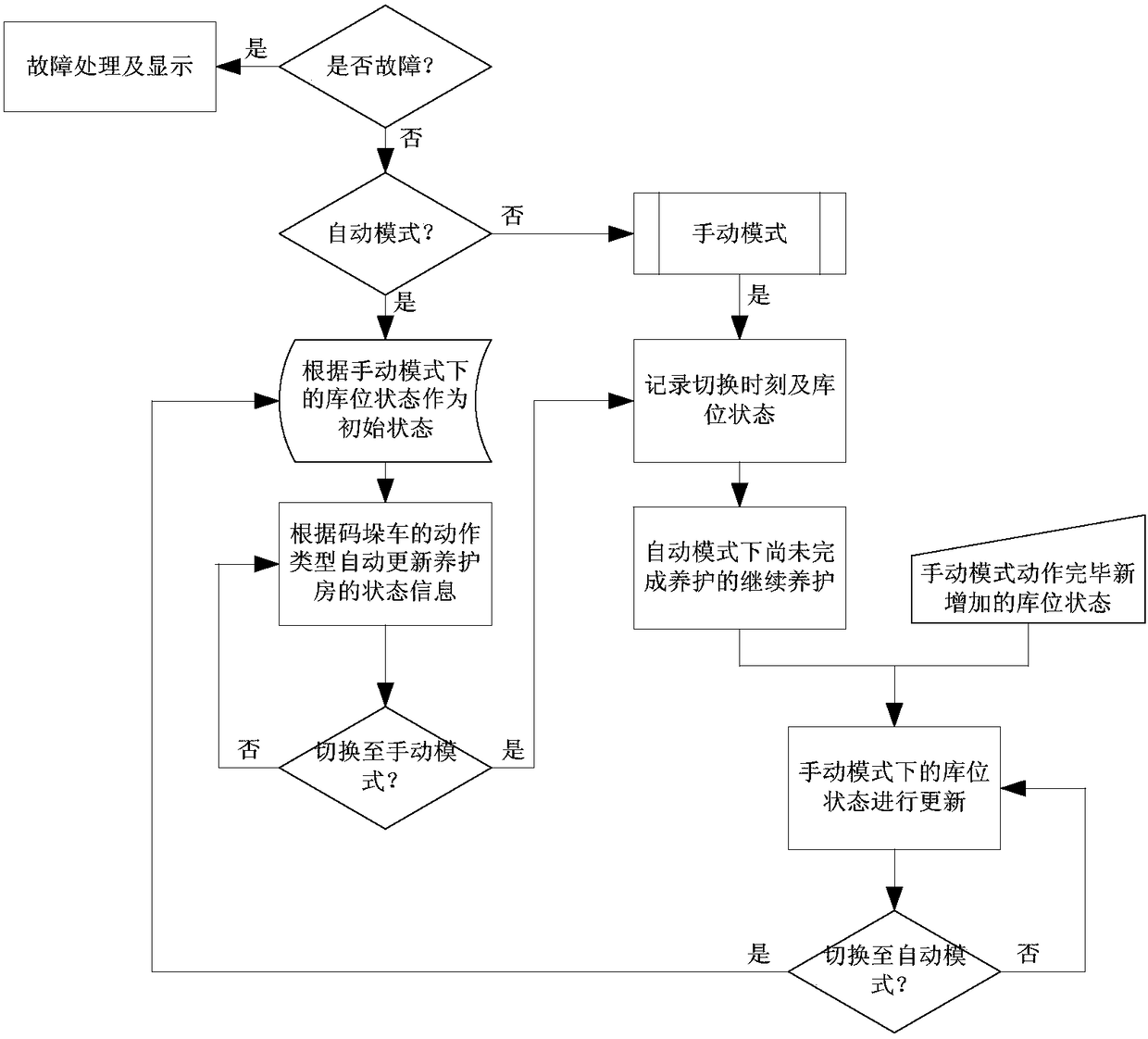

Maintenance state control system and control method in the maintenance room of the concrete precast slab production line

ActiveCN105739470BThe maintenance status is clear and controllableIncrease productivityControl devices for conveyorsStacking articlesProduction lineMode control

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap