Method for preparing iron-cobalt-nitrogen codoped graphene at low temperature

A nitrogen-doped graphene and graphene technology, which is applied in the field of low-temperature preparation of iron-cobalt-nitrogen co-doped graphene, can solve the problem of inability to easily infer the precise structure of the final synthesis catalyst, high cost and large-scale commercialization, and catalytic mechanism research difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

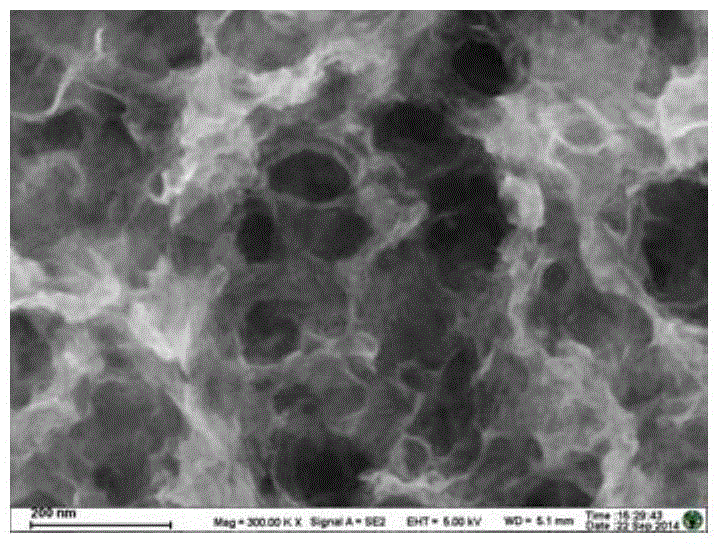

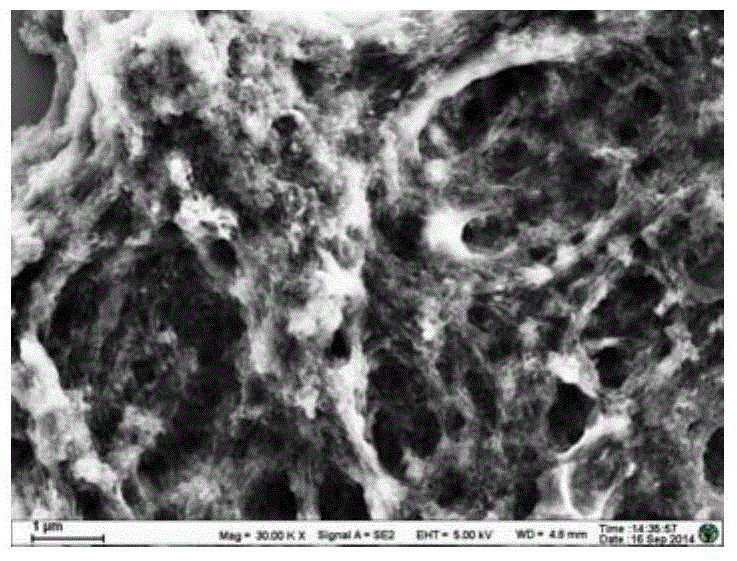

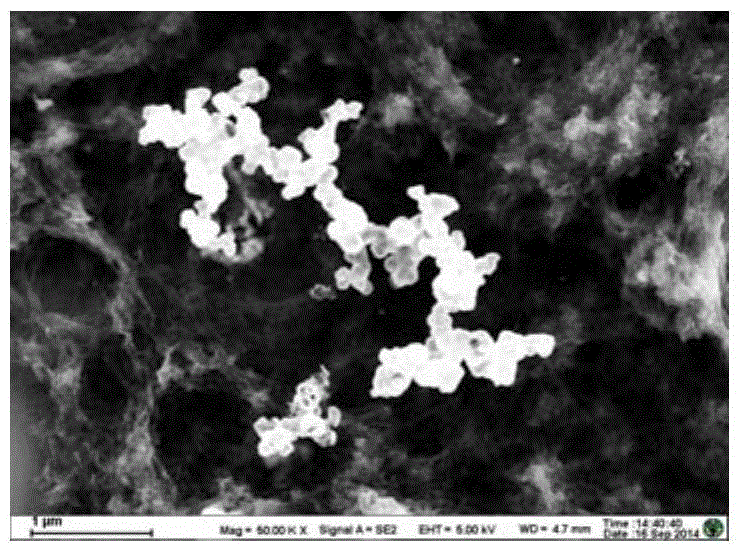

Image

Examples

Embodiment 1

[0020] Embodiment 1 The preparation of graphene oxide dispersion liquid

[0021] Add 17 mL of concentrated sulfuric acid and 0.37 g of sodium nitrate into the flask. At the same time, stir vigorously for 10 min to completely dissolve the sodium nitrate in the concentrated sulfuric acid; then take 0.5 g of graphite and add it into the flask, then weigh 2.5 g of potassium permanganate and slowly add it into the flask while keeping the system temperature below 20 °C; After all the potassium manganate was added, the ice bath was removed and replaced with a water bath at 35 °C to continue the reaction for 3 h; then, 125 mL of water was slowly added to the flask, and then 2 mL of H 2 o 2 , a large amount of bright yellow precipitate was generated; subsequently, the above bright yellow precipitate was centrifuged at 15,000 rpm for 15 min, and the supernatant was discarded; and washed 5 times with dilute hydrochloric acid with a volume ratio of 1:10; then, replace dilute Hydrochlori

Embodiment 2

[0023] Take 20 mL of the 0.5 mg / mL graphene oxide dispersion prepared in Example 1, add 80 mg of guanidine phosphate, and place it at 180 °C for 24 h to prepare nitrogen-doped graphene;

Embodiment 3

[0025] Take 20 mL of the 0.5 mg / mL graphene oxide dispersion prepared in Example 1, add 80 mg of guanidine phosphate and 3 mg of ferrous chloride, and place it at 180°C for 24 h to obtain iron-nitrogen co-doped Graphene; in the LSV test, the absolute value of the current density of iron-nitrogen co-doped graphene at the potential of -0.8 V is 5.72 mA / cm2, which is greater than that of the platinum-carbon catalyst at -0.8 V. The absolute value of the current density is 5.69 mA / cm square centimeters;

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap