Composite cathode of microbial fuel cell and preparation method and application thereof

A fuel cell and composite cathode technology, applied in the field of bioelectrochemistry, can solve the problems of poor electrical conductivity of magnesium oxide, and achieve the effects of low cost, stable operation, and high electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

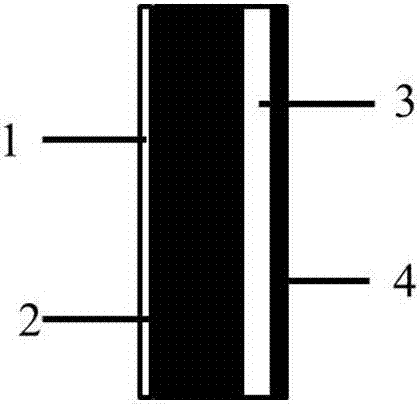

Method used

Image

Examples

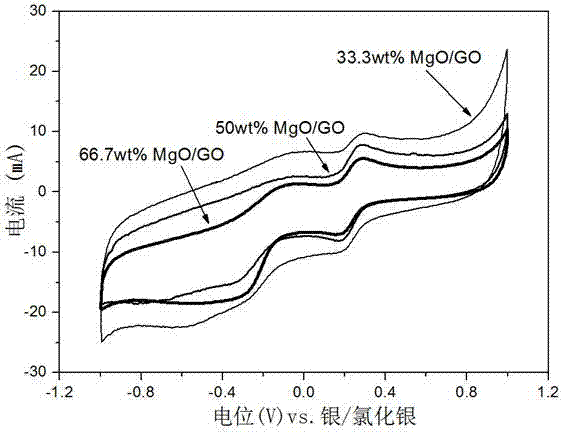

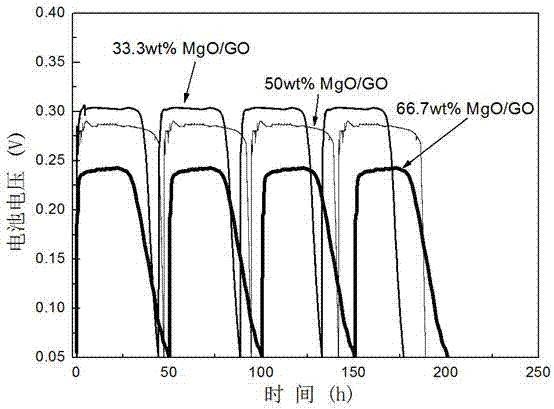

Embodiment 1

[0064] The preparation of graphene oxide / magnesia composite material specifically comprises the following steps:

[0065] Take 0.3g of graphene oxide and disperse it in 300ml of deionized water, ultrasonicate for 64min, then add magnesium oxide to the dispersion liquid according to the mass ratio of magnesium oxide and graphene oxide at 0.5:1, and stir at a stirring speed of 550rpm / min. Heated in a water bath at 80°C for 60min, then filtered the obtained product and washed it with deionized water for 6 times, and finally dried it in a vacuum oven at 50°C for 28h to obtain 33.3wt% MgO / GO. The surface area of the composite was measured as 453m 2 / g;

[0066] The preparation of the microbial fuel cell composite cathode specifically comprises the following steps:

[0067] (1) Preparation of carbon base layer:

[0068] Mix acetylene black with 42wt% polytetrafluoroethylene solution at a solid-to-liquid ratio of 1:12 mg / ul, and after ultrasonic mixing for 10 minutes, spr

Embodiment 2

[0074] The preparation of graphene oxide / magnesia composite material specifically comprises the following steps:

[0075] Take 0.4 g of graphene oxide and disperse it in 300ml of deionized water, ultrasonicate for 45 minutes, then add magnesium oxide to the dispersion liquid according to the mass ratio of magnesium oxide and graphene oxide as 1:1, and stir at a stirring speed of 350rpm / min. , heated in a water bath at 60°C for 90min, then filtered the obtained product and washed it four times with deionized water, and finally dried it in a vacuum oven at 55°C for 24h to obtain 50 wt% MgO / GO. The surface area of the composite was measured as 468m 2 / g;

[0076] (1) Preparation of carbon base layer:

[0077] Mix acetylene black with 40wt% polytetrafluoroethylene solution at a solid-to-liquid ratio of 1:10mg / ul, mix ultrasonically for 5 minutes, and spread evenly on a carbon cloth with a thickness of 0.41mm. The coating of acetylene black on carbon cloth The amount is

Embodiment 3

[0083] The preparation of graphene oxide / magnesia composite material specifically comprises the following steps:

[0084] Disperse 0.5g of graphene oxide in 300ml of deionized water, ultrasonicate for 75min, then add magnesium oxide into the dispersion according to the mass ratio of magnesium oxide to graphene oxide at 2:1, heat in a water bath at 68°C for 100min while stirring The speed was 420rpm / min, and then the obtained product was filtered and washed 5 times with deionized water, and finally dried in a vacuum oven at 60°C for 20h to obtain 66.7 wt% MgO / GO, and the surface area of the composite was measured to be 436m 2 / g;

[0085] (1) Preparation of carbon base layer:

[0086] Mix acetylene black with 38wt% polytetrafluoroethylene solution at a solid-to-liquid ratio of 1:13mg / ul, mix ultrasonically for 8 minutes, and spread evenly on carbon cloth with a thickness of 0.38mm. The coating of acetylene black on carbon cloth The amount is proportional to 1.56mg /

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap