Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Plasma polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

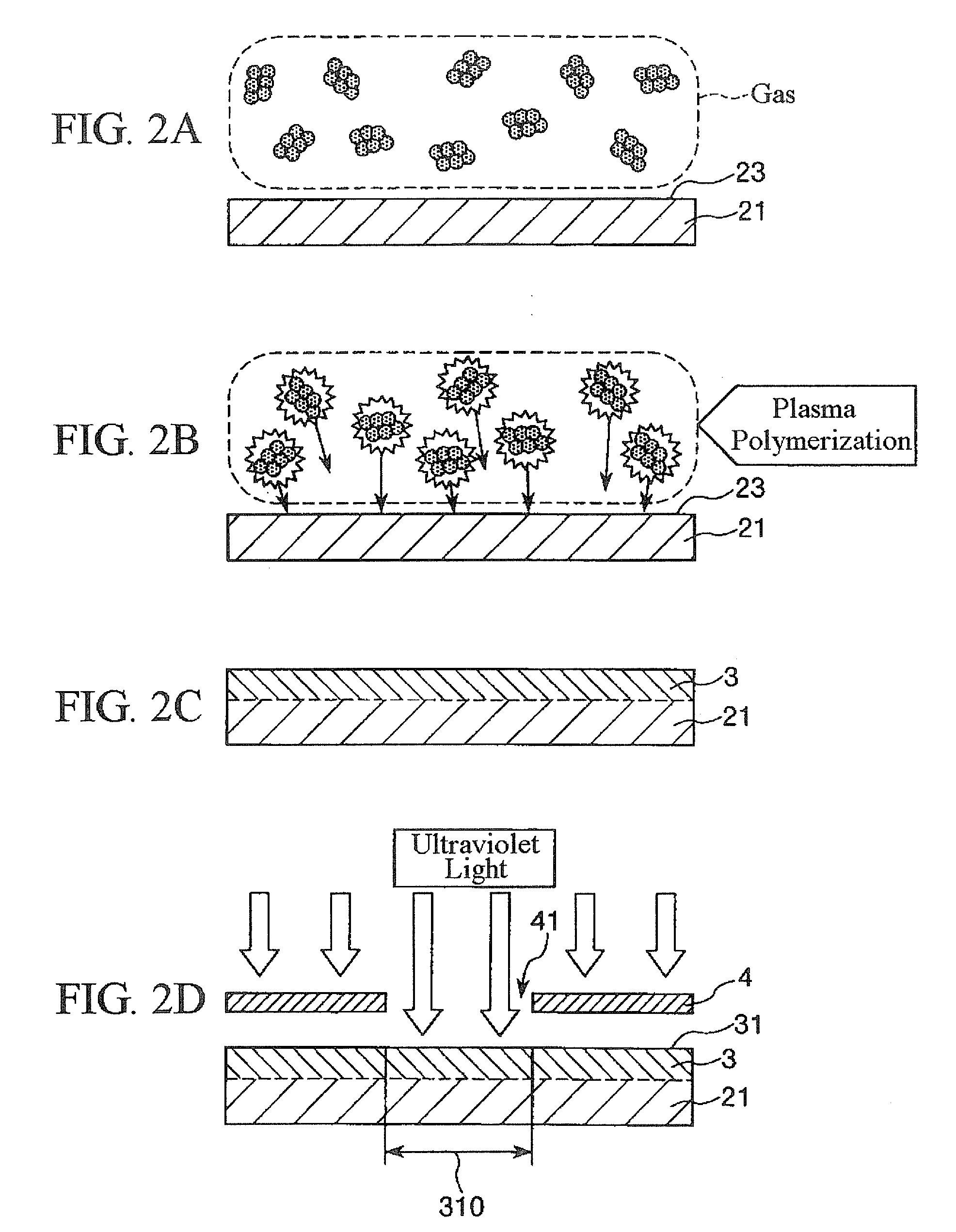

Plasma polymerization (or glow discharge polymerization) uses plasma sources to generate a gas discharge that provides energy to activate or fragment gaseous or liquid monomer, often containing a vinyl group, in order to initiate polymerization. Polymers formed from this technique are generally highly branched and highly cross-linked, and adhere to solid surfaces well. The biggest advantage to this process is that polymers can be directly attached to a desired surface while the chains are growing, which reduces steps necessary for other coating processes such as grafting. This is very useful for pinhole-free coatings of 100 picometers to 1 micrometre thickness with solvent insoluble polymers.

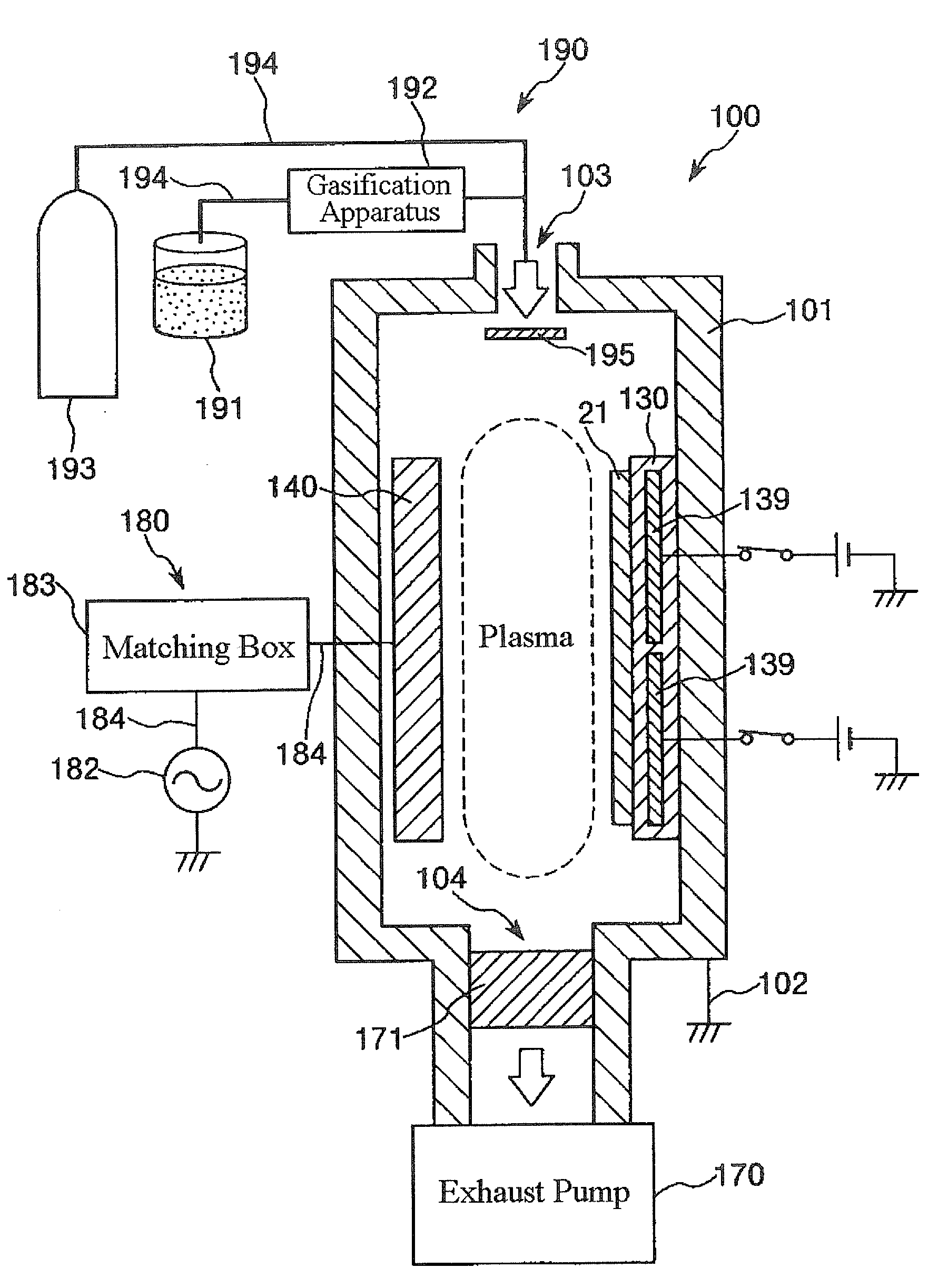

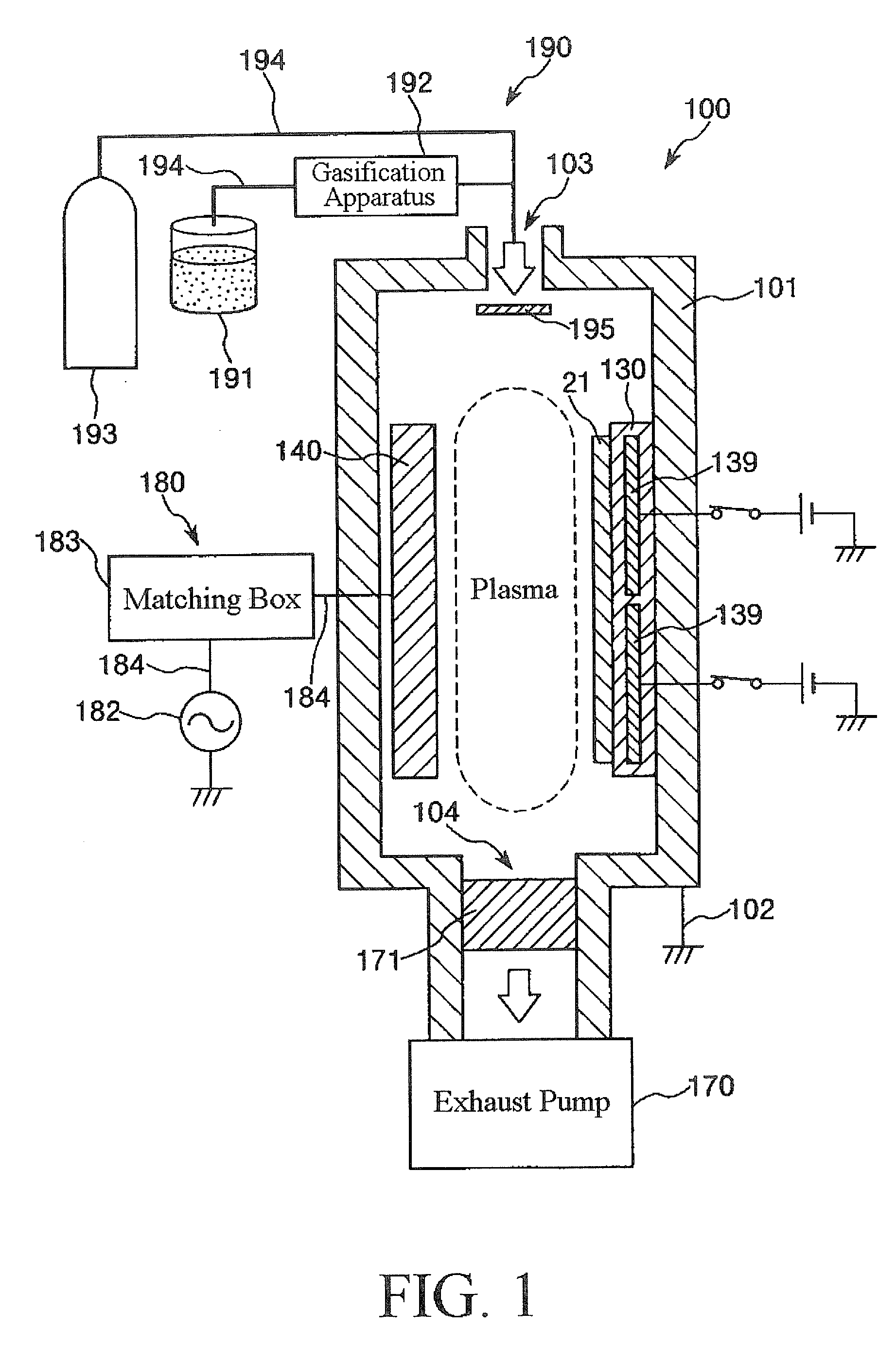

Bonding method, bonded body, droplet ejection head, and droplet ejection apparatus

InactiveUS20100193120A1Lamination ancillary operationsAdhesive processes with surface pretreatmentPlasma polymerizationMaterials science

Owner:SEIKO EPSON CORP

Plasma preparation method of polystyrene fluorescent microspheres and reaction equipment of plasma preparation method

ActiveCN105713126ALong fluorescence lifetimeImprove thermal stabilityLuminescent compositionsOrganic synthesisPolystyrene

The invention discloses a plasma preparation method of polystyrene fluorescent microspheres and reaction equipment of the plasma preparation method, and relates to the technical field of organic synthesis of fluorescent microspheres. A rare earth organic complex is adopted as a starting raw material, plasma of polystyrene is polymerized on the surface of the rare earth organic complex to coat the surface of the rare earth organic complex with a layer of polystyrene, and thus polystyrene fluorescent microspheres are formed. The method includes the main steps of 1, performing plasma pretreatment of the rare earth organic complex; 2, performing plasma polymerization, wherein plasma of polystyrene monomers is polymerized and deposited on the surface of the rare earth organic complex. The polystyrene fluorescent microspheres obtained through the preparation method have a long fluorescent lifetime and good heat stability, and the preparation process is simple, easy to perform and free of environmental pollution.

Owner:HEBEI NATAI CHEM IND CO LTD

Preparation method of polyacrylamide reverse-phase emulsion

Owner:SHANDONG UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap