Ultrasonic fingerprint recognition module and manufacturing method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

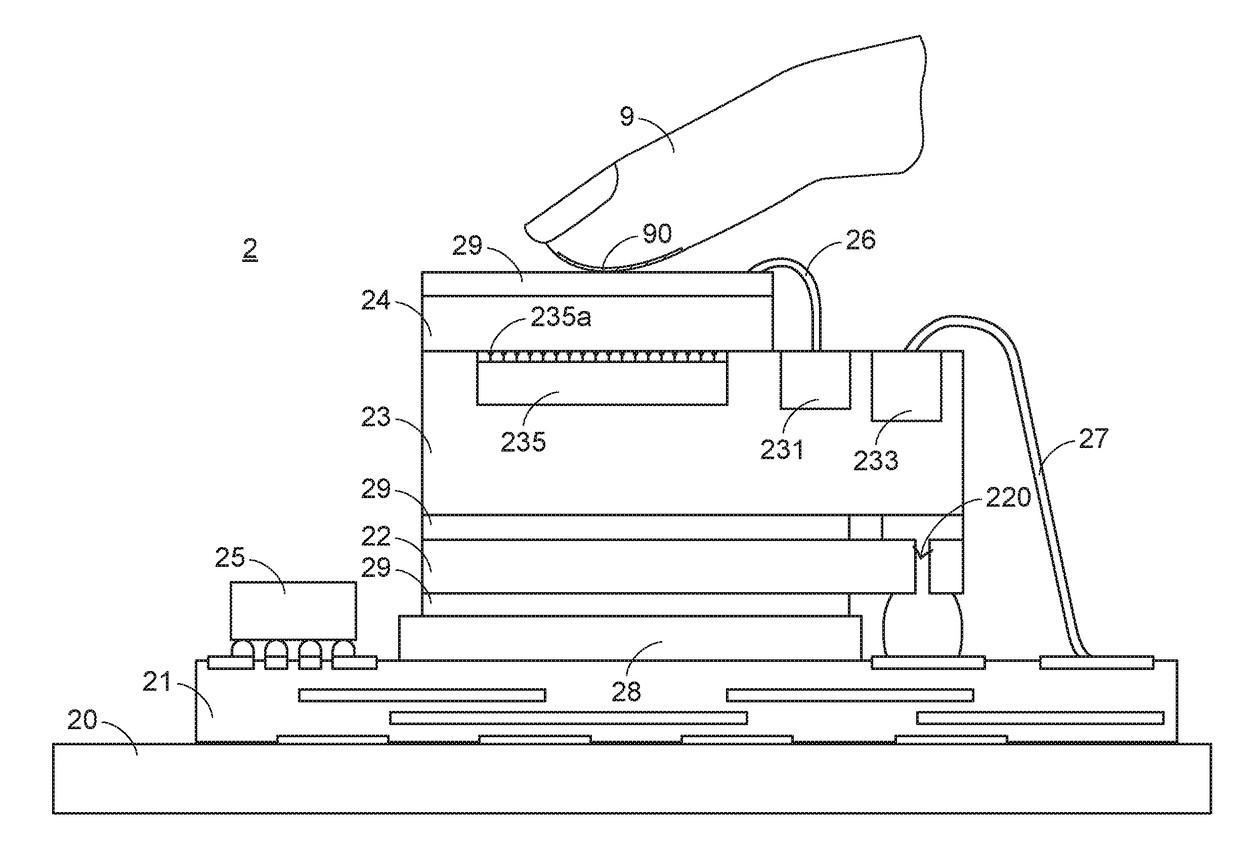

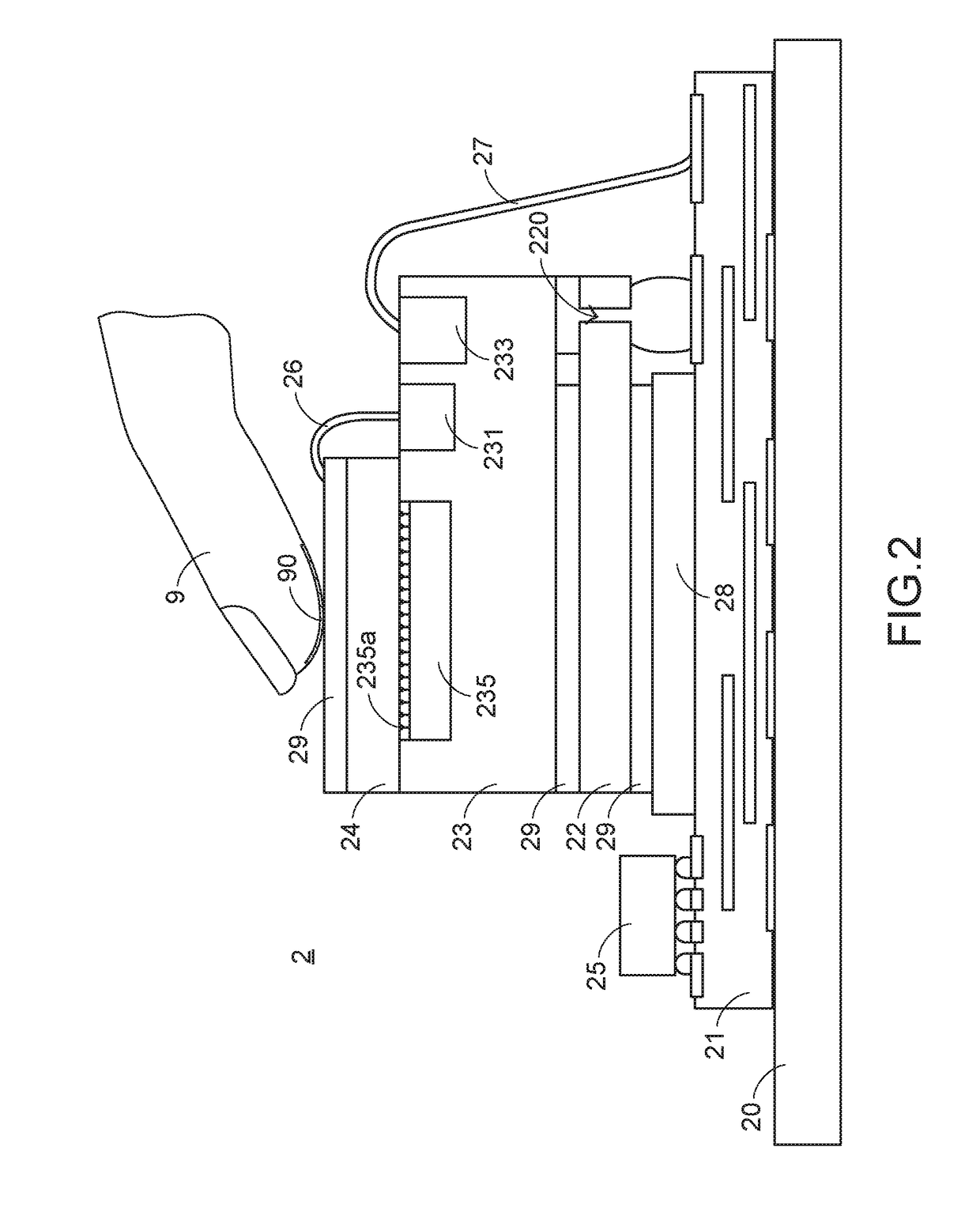

[0029]FIG. 2 is a schematic cross-sectional view illustrating an ultrasonic fingerprint recognition module according to a first embodiment of the present invention. As shown in FIG. 2, the ultrasonic fingerprint recognition module 2 comprises a substrate 21, an ultrasonic transmitter 22, a thin film transistor (TFT) 23, an ultrasonic receiver 24, a first wire 26 and a second wire 27. The above components will be described according to the sequence from bottom to top.

[0030]The substrate 21 is located at a bottom side. The ultrasonic transmitter 22 is stacked over the substrate 21. The thin film transistor 23 is stacked over the ultrasonic transmitter 22. The ultrasonic receiver 24 is stacked over the thin film transistor 23. The two ends of the first wire 26 are connected with the ultrasonic receiver 24 and a first electric pad 231 of the thin film transistor 23, respectively. Consequently, the ultrasonic receiver 24 and the thin film transistor 23 are electrically connected with each o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap