Full automatic extraction device

An extraction instrument, fully automatic technology, applied in solvent extraction, chemical instruments and methods, laboratory utensils, etc., can solve the problems of manual cleaning of experimental containers, troublesome operation, and unfavorable health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

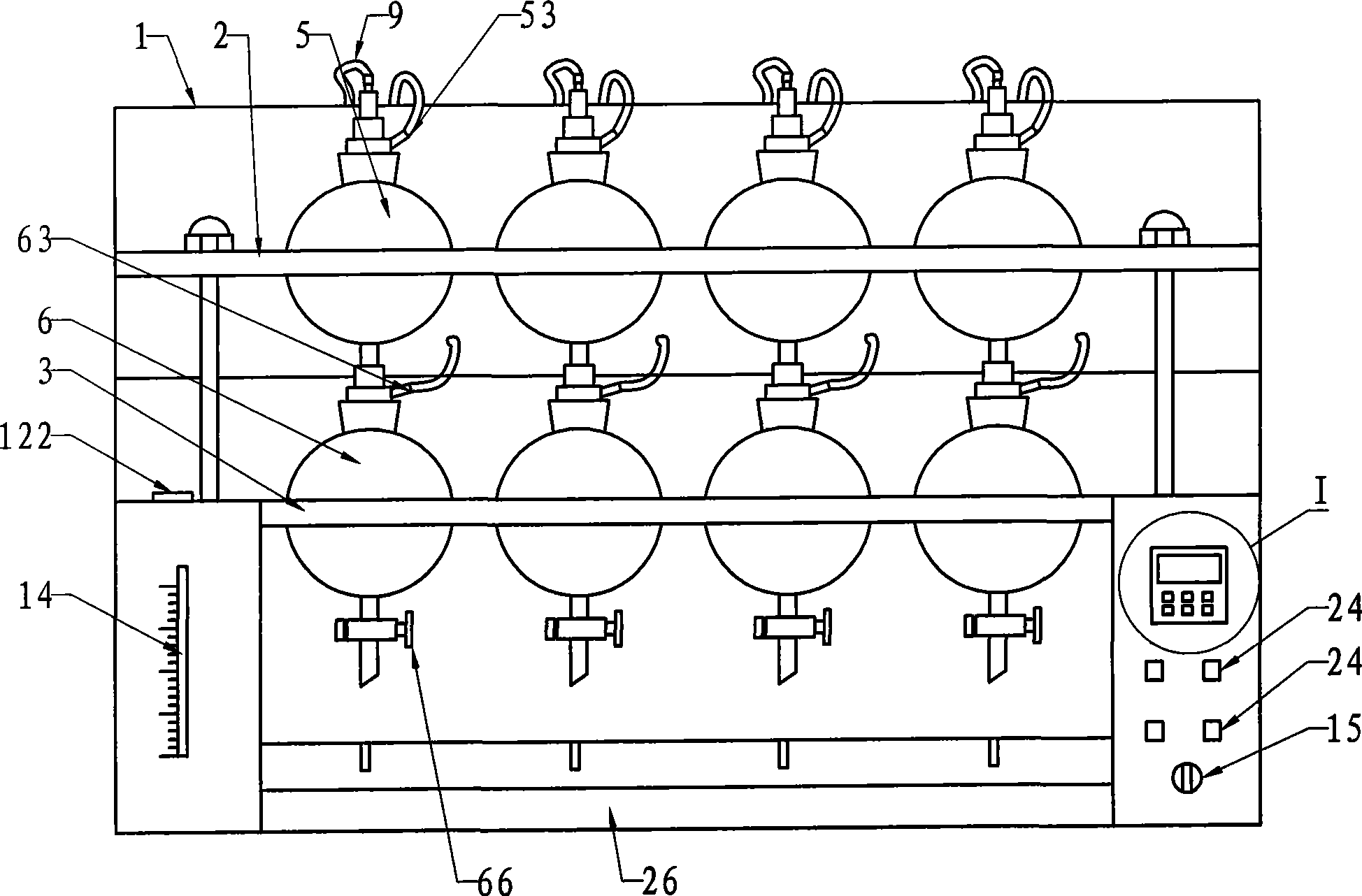

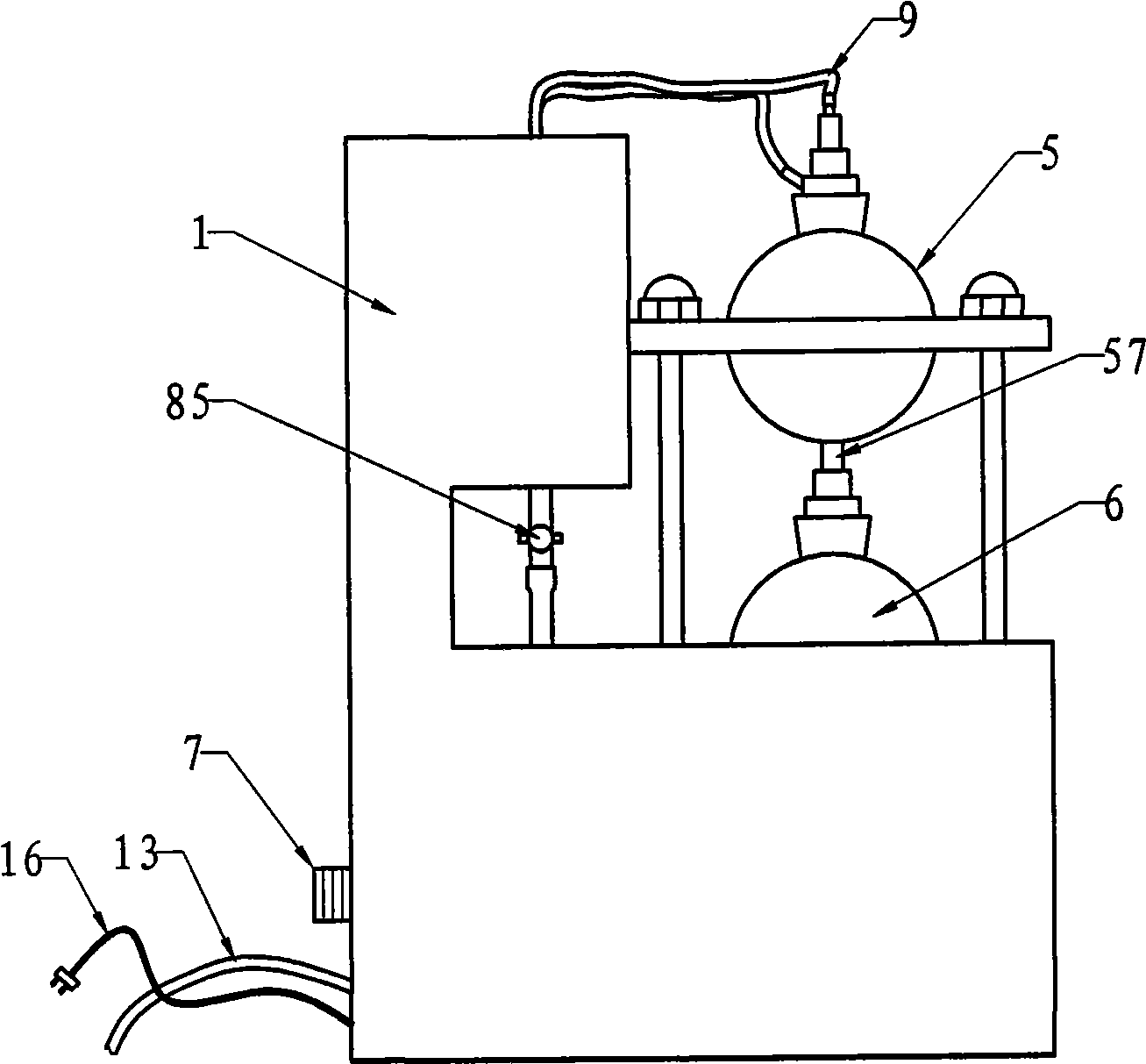

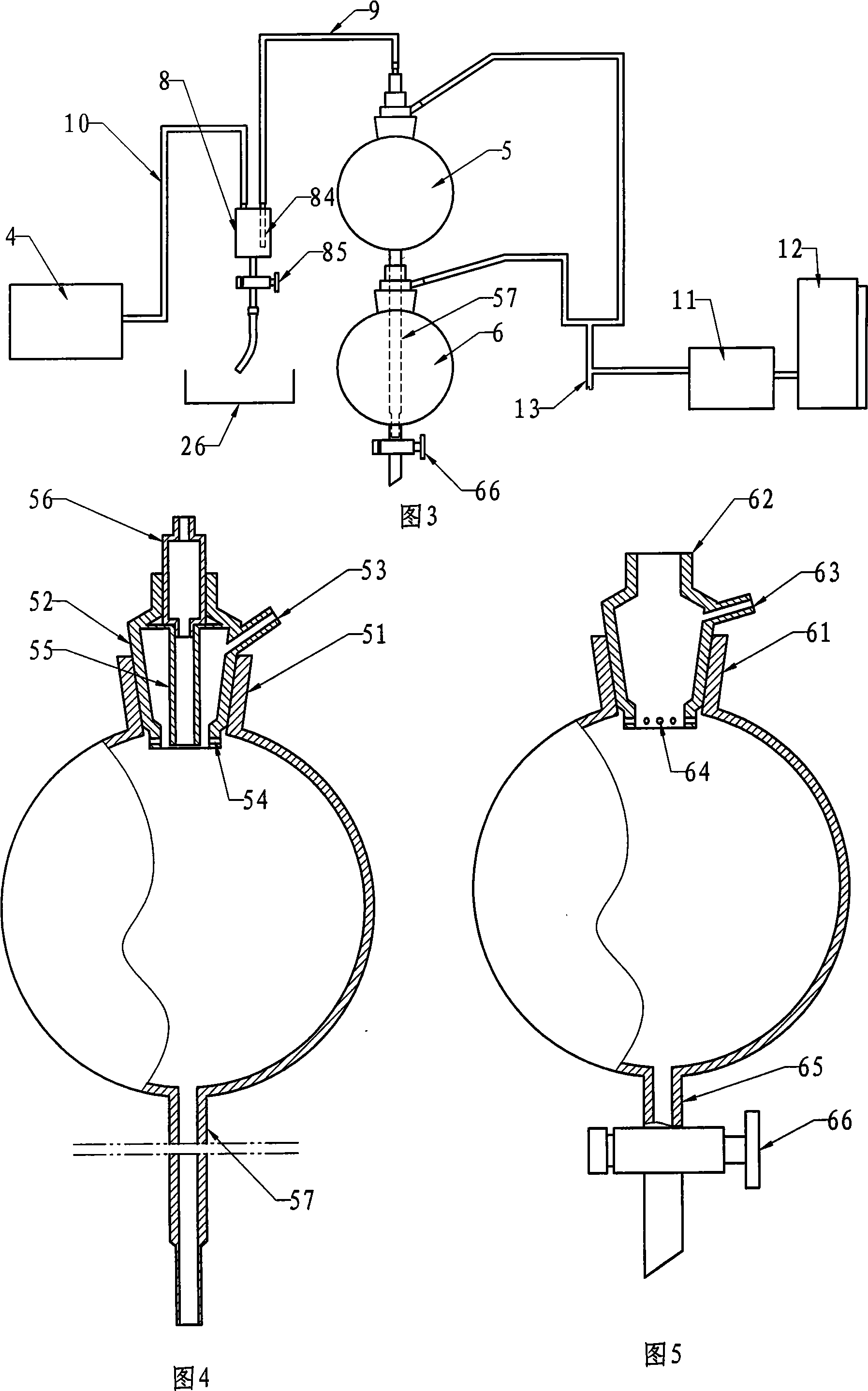

[0023] Such as figure 1 , figure 2 As shown, the automatic extraction instrument mainly includes a housing 1, a vacuum pump 4, an extraction container 5, and a separatory funnel 6. The vacuum pump 4 is arranged in the housing 1, and its output port is connected with an exhaust pipe 7, and the exhaust pipe 7 is drawn out from the rear of the housing.

[0024] The extraction container 5 is fixedly mounted on the upper fixing plate 2 of the housing, and the separating funnel 6 is fixed on the lower fixing plate 3 of the housing.

[0025] As shown in FIG. 4 , the extraction container 5 is a spherical bottle, the top of which is provided with a bottle opening 51 , and the bottom of the extraction container 5 is provided with a long pipe 57 for absorbing liquid. The bottle mouth 51 is fitted with a flushing plug 52 in a sealed manner. The flush plug 52 is provided with an inner cavity, and the top and bottom ends are provided with openings communicating with the inner cavity, and a

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap