Multi-user digital laser imaging system

a laser imaging system and multi-user technology, applied in the field of medical laser imaging systems, can solve the problems of only being able to exercise a limited degree of control over the overall imaging system transfer function, and unable to account for drift in the overall system transfer function, so as to achieve the effect of minimizing differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

System Overview

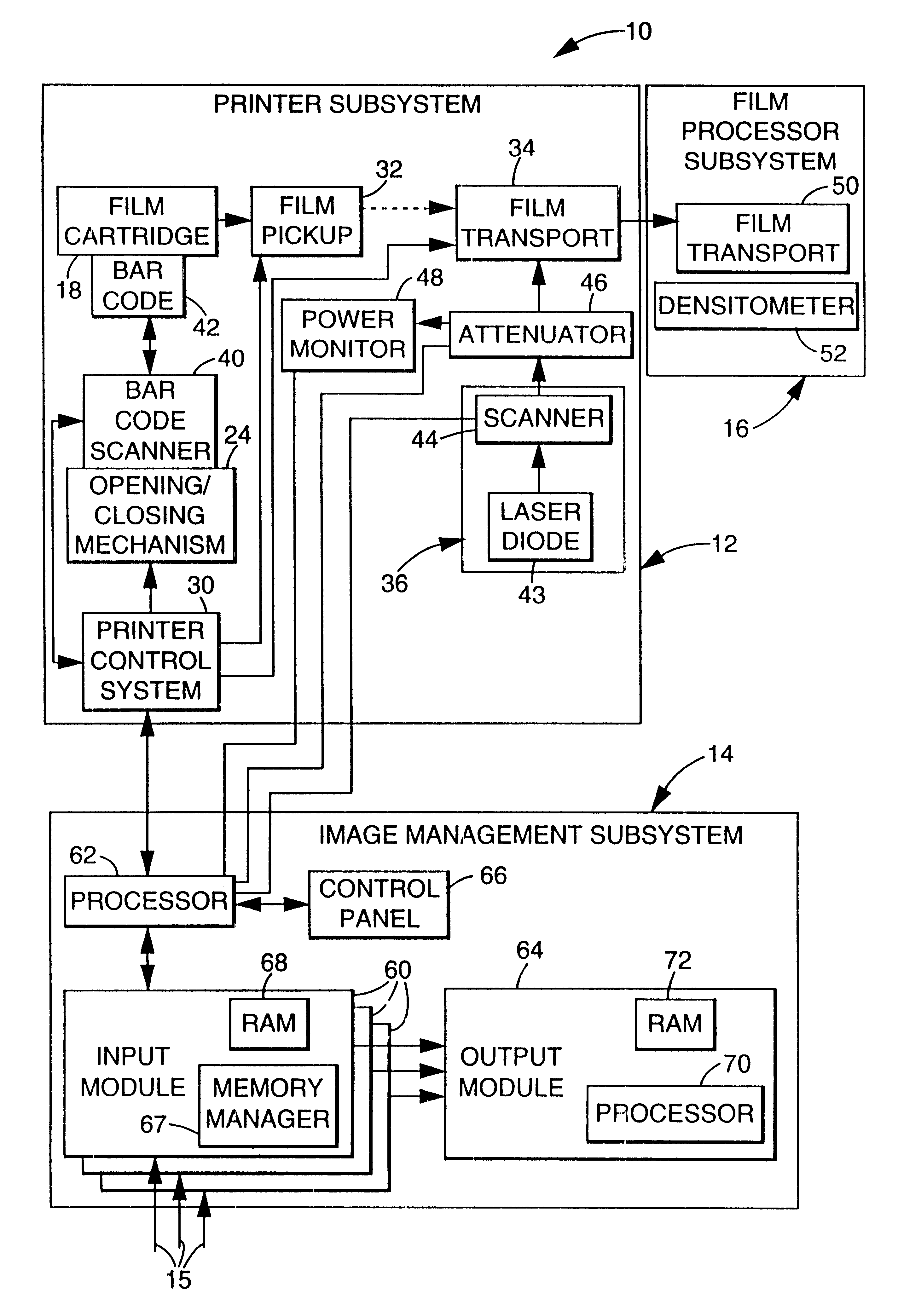

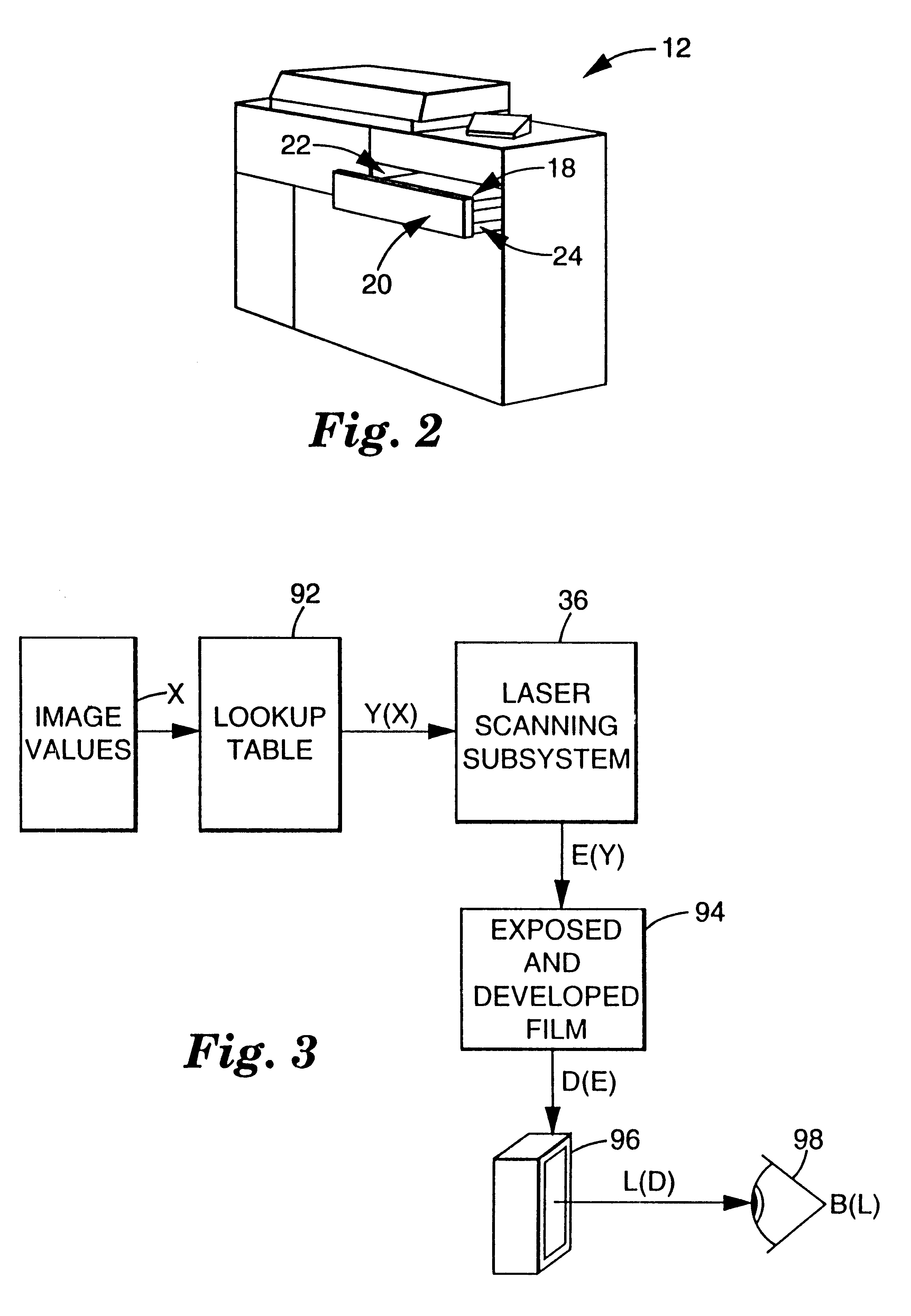

A multi-user digital laser imaging system 10 in accordance with the present invention is illustrated generally in FIG. 1. As shown, laser imaging system 10 includes laser diode printer subsystem 12, image management subsystem 14 and media processor subsystem 16. Printer subsystem 12 is a continuous tone laser imager in one embodiment, and is configured to receive resealable cartridges 18 which contain sheets of radiographic film (not separately shown). Image management subsystem 14 includes input ports 15 through which digital image values generated by a magnetic resonance (MR), computed tomography (CT) or other type of scanner are provided to imaging system 10. The image values are processed by image management subsystem 14 to generate laser drive values which are applied to printer subsystem 12 to image or expose film removed from cartridge 18. The printed film is subsequently developed by processor subsystem 16 to produce a hardcopy of the image. Imaging system 10 is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap